Fastener Bolts: The Backbone of Industrial Connections

What is a Fastener Bolt?

Fasteners are utilized to attach and secure a wide range of materials, such as wood, metal, plastic, or concrete. These can come in different types, such as nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and many others.

Fastener bolts are mechanical components used for joining two or more objects together by creating a secure, threaded connection. They consist of a cylindrical body with external helical threads, a head at one end for turning with a wrench or other tool, and often a washer and nut to provide additional stability and tightening force.

Types of Fastener Bolts

Fastener bolts come in various types, each designed for specific applications and requirements. Here are some of the most commonly used types of fastener bolts:

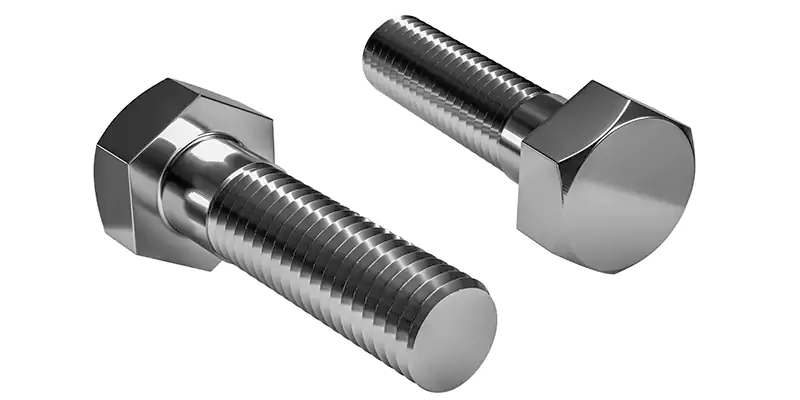

Hex bolts

Hex bolts have a distinctive head shape that resembles a six-sided hexagon. The hexagonal shape allows for multiple angles of approach when tightening or loosening the bolt, making it easier to reach bolts in hard-to-reach locations. This feature is particularly important in applications where access is limited.

Due to their ease of assembly and disassembly, hex bolts are commonly used in machining and other industrial settings. They provide a strong and reliable fastening solution that can be quickly and easily adjusted or removed when necessary.

Carriage bolts

Carriage bolts have a distinctive design that includes a convex metal head, a square neck, and threads. They are commonly used to fasten wood materials, as the square neck can easily fit into a pre-drilled hole in the wood by applying pressure. This design allows the bolts to have a self-locking potential, preventing them from rotating or slipping out of place.

Flange bolts

They are similar to hex bolts but have a wider flange under the bolt head that provides a larger bearing surface and distributes the load more evenly. The flange also acts as a washer, eliminating the need for a separate washer to be used with the bolt.

One of the key advantages of flange bolts is their ability to distribute the load more evenly, which helps to prevent damage or distortion of the material being fastened. They are also less likely to loosen over time due to their larger bearing surface and locking properties.

Stud bolts

These bolts have threads on both ends and are commonly used in flanged connections where a nut is used to tighten the joint.

Lag bolts

Lag bolts, also known as wood screws, are a type of fastener commonly used in construction and woodworking applications. Unlike standard bolts that require a nut to secure the connection, lag bolts feature a pointed tip and large threads that are designed to thread directly into wood or other soft materials.

U-bolts

U-bolts have a unique shape resembling a horseshoe, with a bent section that does not contain threads. The straight ends of the U-bolt have threads all the way along. U-bolts are commonly used for holding tubes and pipes in position without the need for drilling holes.

Eye bolts

These bolts have a loop or eye at one end and are commonly used to secure cables or ropes.

J-bolts

These bolts have a J-shaped body and are commonly used for securing concrete or other materials to a surface.

How to Choose a Proper Bolt?

Selecting the appropriate mechanical fastener from the vast range available is crucial. It is not only essential for enhancing productivity but also for ensuring the safety of the workers and the process. Therefore, it is imperative to understand how to always make the right choice when choosing a fastener.

Know the applications

There is a wide range of mechanical fasteners to choose from, but selecting the right one for many applications is essential. Choosing the correct fastener is not only vital for productivity, but it is also crucial for the safety of the workers and the process. Therefore, it is important to understand how to choose the appropriate fastener for your application at all times.

Construction

Bolts are used in construction for joining steel beams, connecting wood framing, and securing building materials to foundations.

Automotive

Bolts are used extensively in the automotive industry for assembling engines, suspensions, and other components.

Aerospace

Bolts are used in the aerospace industry for fastening aircraft components such as wings, fuselages, and landing gear.

Manufacturing

Bolts are used in manufacturing for assembling machinery, equipment, and other components.

Infrastructure: Bolts are used in infrastructure for securing bridges, tunnels, and other large-scale structures.

Electronics

Bolts are used in electronics for securing components and attaching devices to frames or enclosures.

Marine

Bolts are used in the marine industry for fastening ship components such as hulls, decks, and masts.

Select the right dimension

Dimension selection is another important factor when choosing a fastener. Threads are crucial parts of an application, as well as length, head diameter, thickness, shank diameter, nut, and washer sizes.

Thread

The thread of a fastener bolt can vary in size and shape depending on the application and the type of bolt being used. Some common thread types include coarse thread, fine thread, and metric thread.

Coarse thread bolts have a greater distance between each thread, making them ideal for fastening into softer materials such as wood or plastic.

Fine thread bolts have a smaller distance between each thread, providing a stronger grip, and are commonly used in metal applications.

Metric thread bolts use a standardized thread size and pitch, allowing for easy interchangeability and compatibility with other metric fasteners.

Length

The length of the bolt is measured from the bottom of the head to the end of the shank. It’s important to choose a bolt that is long enough to pass through all materials being fastened.

Head diameter and thickness

The head diameter refers to the width of the bolt’s head, while the thickness refers to the height of the head. These dimensions will determine the size of the wrench or socket needed to tighten the bolt.

Shank diameter

The shank diameter refers to the thickness of the bolt’s body, excluding the head. The shank diameter is an important consideration when selecting bolts for a specific application, as it affects the strength and load-carrying capacity of the bolt.

Shank diameters of fastener bolts can vary depending on the size and type of bolt. For example, a standard hex head bolt with a diameter of 1/4 inch may have a shank diameter of around 0.206 inches, while a larger bolt with a diameter of 1 inch may have a shank diameter of around 0.850 inches.

Nuts and washer sizes

Nuts and washers are used to secure and distribute the load on the bolt, and they must be compatible with the size and thread pitch of the bolt.

The size of a nut is typically designated by its nominal diameter, which is the distance across the flats of the nut. For example, a 1/4-inch bolt would typically require a 1/4-inch nut. However, it’s important to note that the thread pitch of the bolt must also be taken into account when selecting a nut, as it must match the thread pitch of the bolt to ensure proper fit and load distribution.

Materials Used for Bolts

To avoid the risks of thread stripping or galling, it is recommended to use fasteners made of hard materials. When thread surfaces are in contact, pressure can build up, leading to increased friction, fusion, or seizing of the fastener. Therefore, selecting the appropriate fastener material is crucial to prevent these issues.

Carbon Steel

This is the most common material used for bolts due to its strength and affordability. It is suitable for most applications where high strength and moderate corrosion resistance are required.

Stainless Steel

This material is highly resistant to corrosion and is often used in applications where the bolt is exposed to harsh environments or corrosive substances.

Titanium

This material is known for its high strength-to-weight ratio, making it suitable for applications where a strong and lightweight bolt is required.

Aluminum

This material is lightweight and corrosion-resistant, making it suitable for applications where weight is a concern or the bolt will be exposed to corrosive substances.

Brass

This material is often sold and used for decorative purposes due to its attractive appearance, but it is also suitable for applications where a non-corrosive bolt is required.

Nickel Alloy

This material is highly resistant to corrosion and high temperatures, making it suitable for use in extreme environments.

Bolt installation and tightening

Before officially using bolts, there are still a few steps to do! Proper installation and tightening of bolts are essential for ensuring a strong and secure connection. Here are some general guidelines for bolt installation and tightening:

Pre-Installation

Make sure the threads on the bolt and nut are clean and free from debris. Check the dimensions of the bolt, nut, and washer to ensure they are the correct size for the application.

Lubrication

Apply lubricant to the threads of the bolt to reduce friction during tightening. This can help to prevent galling and ensure a more accurate torque reading.

Torque

Tighten the bolt to the specified torque using a torque wrench. Over-tightening can cause damage to the bolt or the material being fastened, while under-tightening can result in a weak or insecure connection.

Tightening Pattern

When tightening multiple bolts, follow a specific pattern to ensure even distribution of the load. For example, in a four-bolt pattern, tighten bolts 1 and 3, then bolts 2 and 4, in a diagonal pattern.

Re-Tightening

After installation, check the torque of the bolt periodically, as bolts can loosen over time due to vibration or settling.

Conclusion

In conclusion, fastener bolts are the backbone of industrial connections, serving a critical role in joining materials and components together in a wide range of applications across various industries. With their wide range of sizes, materials, and designs, bolts offer versatility and flexibility in meeting the demands of different applications. However, CapableMachining thinks proper installation and tightening are crucial to ensure a strong and secure connection that will withstand the forces and stresses placed upon it.

From construction and automotive to aerospace and marine industries, bolts play a vital role in ensuring the safety and reliability of our infrastructure, machinery, and equipment. As such, they will continue to be a fundamental component of industrial connections for years to come.