Four Common Methods in Rapid Prototyping

The prototype is the initial sample of a certain product, and rapid prototyping means making samples quickly. In different stages of product development, for different products, the purpose of making samples is different. In general, there are three kinds of purposes for making samples: verifying the function, verifying the appearance, and verifying the mass production process. According to these three different types of purposes, rapid prototyping adopts different processes. Among these processes, four are utilized most often: 3D printing, CNC machining, vacuum casting (urethane casting), and rapid molding.

When choosing what technology

If you want to verify the appearance or basic shape of the product, 3D printing of plastic products is usually the best choice. Metal products can choose CNC processing or 3D printing. Metal 3D printing is still very expensive. In general, CNC processing will be relatively cheap. Of course, for some very complex parts, such as a curved pipe structure, CNC machining will be difficult to achieve.

If you want to verify a certain function or a certain force situation, such as whether the rotating fan blade will break at the required speed, the prototype must use a specific material, so CNC machining will be more suitable. Due to the different forming principles of the 3D printing process, the strength of the material will be greatly different when the product is used in the future.

If you want to verify the defect rate or consistency during mass production, you must use a process as close to mass production as possible. For example, injection molding is used in mass production, and rapid mold injection molding is used at this time.

Vacuum casting is normally utilized when 3D printing can not provide the right material or when the quantity required is too less for injection molding but too much for 3D printing. Vacuum casting is most suitable for the production of a few dozen to a few hundred prototypes. However, with the ever-increasing of labor cost, rapid injection molding is more and more used to replace vacuum casting.

The 4 Rapid Prototyping Methods

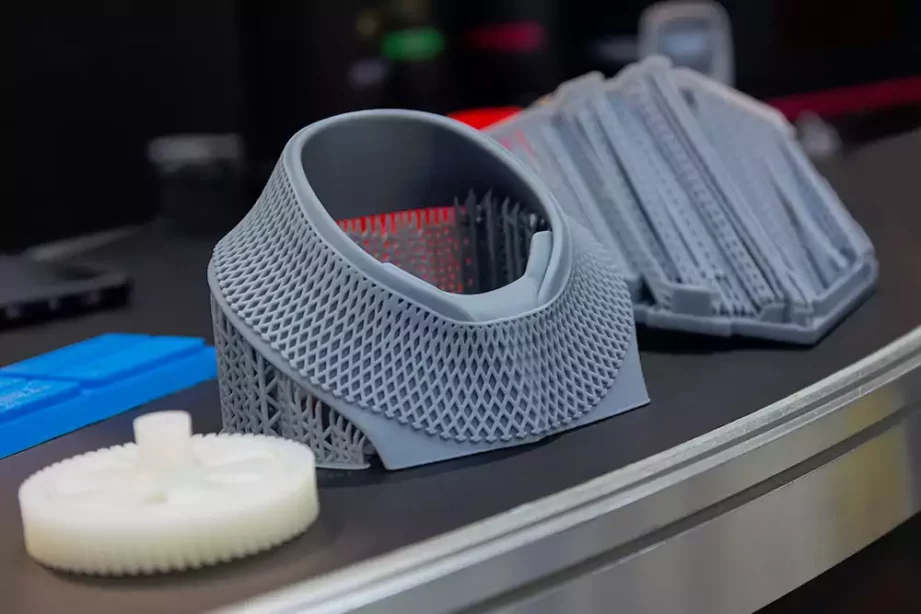

3D Printing

Additive manufacturing, also known as 3D printing, is a method of creating three-dimensional objects using a computer-aided design (CAD) model or a digital 3D model. It employs various processes where the material is deposited, joined, or solidified under the precise control of a computer. Typically, materials like plastics, liquids, or powder grains are fused together, often in layers, to build the object.

During the 1980s, 3D printing techniques were primarily used for producing functional or visually appealing prototypes, and the term “rapid prototyping” was more commonly used to describe the process. However, by 2019, advancements in precision, repeatability, and material capabilities have elevated 3D printing to the extent that some processes are now considered viable for industrial production. Consequently, the term “additive manufacturing” is often used interchangeably with 3D printing.

One of the significant advantages of 3D printing is its ability to fabricate highly intricate shapes or geometries that would otherwise be challenging to construct manually. This includes creating hollow parts or incorporating internal truss structures to reduce weight. As of 2020, the most widely utilized 3D printing process is fused deposition modeling (FDM), which employs a continuous filament of thermoplastic material.

Since the late 1970s, numerous 3D printing processes have been developed, initially characterized by their large size, high cost, and limited capabilities.

Today, there exists a wide range of additive processes, each distinguished by the method of depositing layers to create parts and the materials employed. Some techniques involve melting or softening the material to form layers, such as selective laser melting (SLM) or direct metal laser sintering (DMLS), selective laser sintering (SLS), fused deposition modeling (FDM), or fused filament fabrication (FFF). Other methods utilize advanced technologies to cure liquid materials, like stereolithography (SLA). Laminated object manufacturing (LOM) involves cutting thin layers and joining them, often using materials such as paper, polymer, or metal.

Particle deposition using inkjet technology prints individual drops of material, with each drop representing a particle or object. Color hot-melt inks are used to produce single-color objects by stacking CMYK drops. Complex 3D models are constructed by fusing overlapping drops into layers as dictated by the sliced CAD file. Inkjet technology enables the creation of solid or open-cell structures based on the printer’s inkjet print configuration. Different methods offer their own advantages and disadvantages, leading some companies to provide a choice of powder and polymer materials for object fabrication.

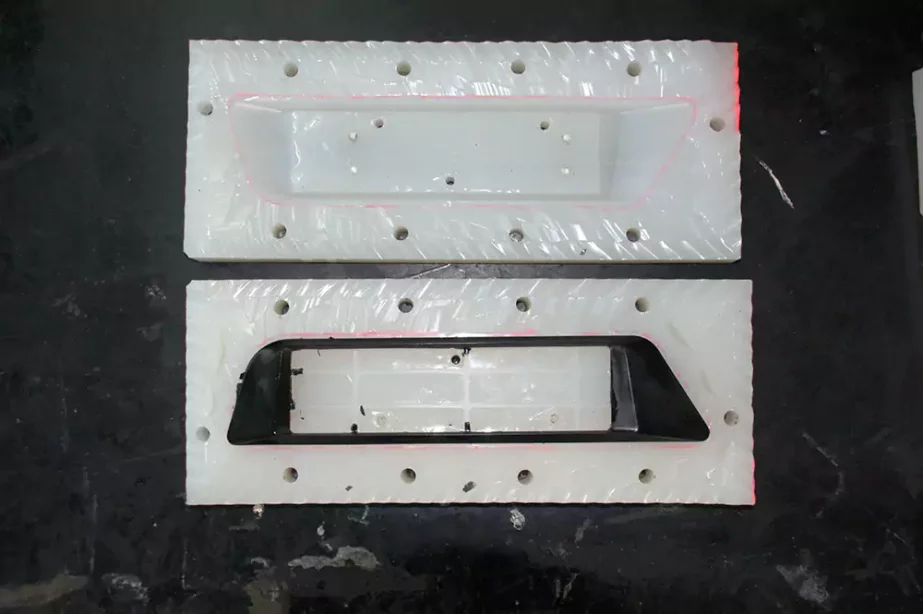

Vacuum Casting

Vacuum Casting is an efficient and cost-effective method commonly employed for rapid prototyping, particularly for producing a limited quantity (typically up to 20) of precise polyurethane prototype parts. Although slightly slower compared to standalone SLA (Stereolithography) processes, Vacuum Casting involves additional manual steps. The manufacturing time depends on the desired characteristics of the part, with size playing a significant role in the material’s curing duration.

To create a small batch of parts, a single master mold is crafted using an SLA master model. This mold, composed of silicone rubber, is utilized to cast resin into it within a vacuum chamber. The outcome is a bubble-free casting, which is ideal for generating highly accurate, functional plastic prototype parts with intricate details that faithfully replicate patterns, dimensions, profiles, and textures.

Vacuum Casting allows for the production of parts with varying levels of flexibility or rigidity, offering a broad spectrum of colors and materials to choose from, including the creation of transparent components.

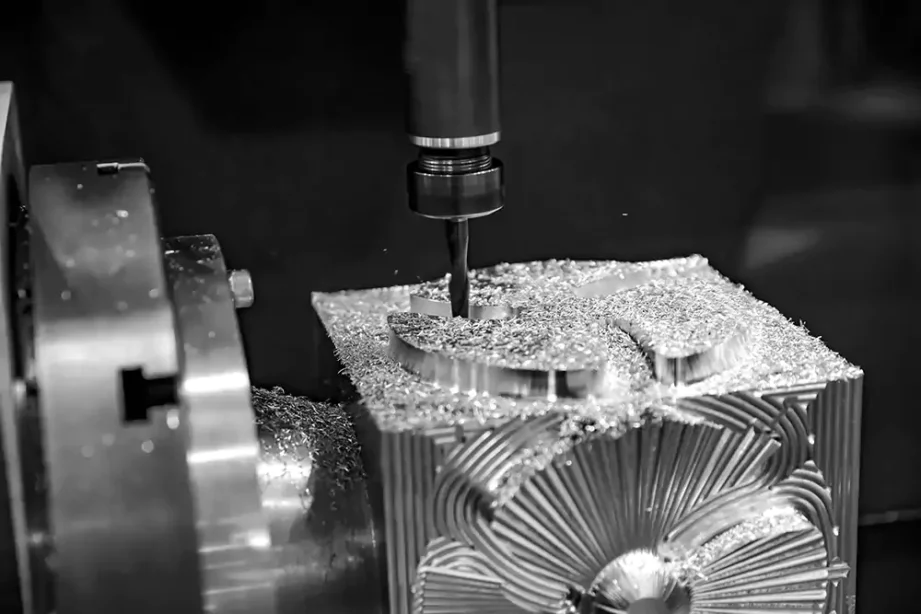

CNC Machining

Numerical control, commonly known as CNC (computer numerical control), is the automated method of controlling machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, through the use of a computer. With CNC, a machine processes a given material (metal, plastic, wood, ceramic, or composite) based on programmed instructions without requiring direct manual intervention from an operator.

A CNC machine consists of motorized maneuverable tools and often a motorized platform, both of which are controlled by a computer according to specific input instructions. These instructions are delivered to the CNC machine in the form of a sequential program that contains machine control codes like G-code and M-code, which are then executed. The program can be manually written by an individual or, more commonly, generated through computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is “sliced” prior to generating the instructions or program, and G-Code is also used in 3D printing.

CNC offers significant improvements in productivity compared to non-computerized machining, particularly for repetitive production tasks that would otherwise require manual control (e.g., using hand wheels or levers) or mechanical guidance through pre-fabricated pattern guides (as seen in pantograph mills). However, it is important to note that these advantages come with substantial costs in terms of both capital expenditure and the setup time required for each job. In certain cases, for prototyping and small batch jobs, a skilled machine operator can produce high-quality parts while the CNC workflow is still being set up.

Rapid Injection Molding

Rapid injection molding is a manufacturing process that enables the rapid production of injection-molded parts for prototyping or low-volume production. It combines the advantages of traditional injection molding with a streamlined and expedited workflow.

The process starts with the creation of a mold, typically made of aluminum or a softer material compared to production-grade molds. The mold is designed to accommodate the desired part geometry. Next, the mold is mounted into an injection molding machine.

The material, often thermoplastic resin, is then injected into the mold under high pressure. The material fills the mold cavities, taking the shape of the desired part. After the material solidifies and cools, the mold is opened, and the part is ejected. This cycle can be repeated multiple times to produce a series of parts.

Rapid injection molding offers several advantages. First, it allows for fast turnaround times, significantly reducing the lead time compared to traditional injection molding. This makes it an ideal solution for prototyping, concept testing, and small production runs. Additionally, rapid injection molding offers cost savings by eliminating the need for expensive and time-consuming production-grade molds.

While rapid injection molding is not suitable for high-volume manufacturing due to the limitations of softer molds, it provides a valuable option for quickly obtaining functional and representative parts. It enables engineers and designers to test and validate their designs, make adjustments, and iterate rapidly before committing to full-scale production.

Conclusion

In conclusion, prototyping is a crucial phase in the product development process that involves creating a tangible representation of a design concept. It allows for testing, validating, and refining ideas before proceeding to full-scale production. Prototyping enables designers, engineers, and stakeholders to visualize and interact with the product, gather feedback, identify design flaws, and make necessary improvements. By facilitating iteration and collaboration, prototyping plays a vital role in ensuring the development of successful and user-centric products. It helps reduce risks, save costs, and accelerate the overall design and innovation process.