How to machine double thread trapezoidal thread on CNC lathe?

For the study of CNC lathe machining double line trapezoidal thread its purpose is to solve the processing problems as well as improve the processing method, combined with the existing CNC machining equipment, optimization of machining procedures and processes, the use of CNC lathe and machining procedures to process out of the double line trapezoidal threaded parts, to be able to meet the requirements of dimensional accuracy, but also optimize the machining of the working hour’s quota. With ordinary lathe equipment processing, labor intensity, low productivity, and high technical requirements for skilled workers, CNC lathe is difficult to ensure high precision and processing quality.

CNC lathe processing can improve productivity, reduce labor intensity, and ensure the processing quality and technical requirements. In addition, in CNC lathe processing double thread trapezoidal thread, the requirements of technical workers are not very high.

Characteristics of double thread trapezoidal thread

There are many kinds of threads, which can be divided into cylindrical threads and conical threads according to the shape of helix formation, and can be divided into connection threads and transmission threads according to different uses, and can be divided into triangular threads, rectangular threads, trapezoidal threads, and serrated threads according to the characteristics of the tooth type, and can be divided into right-handed threads and left-handed threads according to the rotational direction of helix, and can be divided into single threads and multi-threads according to the number of helical threads.

In all kinds of mechanical products, the parts with threads are widely used, especially the transmission threads, which are widely used in the manufacturing industry.

One of them is to play the role of transmission, for example, the long wire rod on the ordinary lathe and the wire rod of the middle and small sliding plate, between the two wire rods is also through the transmission of trapezoidal threads to realize the movement of the working table and the tool holder.

Secondly, it plays the role of connecting steel structures. In steel frame structure, trapezoidal thread is used to connect steel columns and beams to realize stable structural support.

At the same time, trapezoidal threads are also used to fix the connection between the equipment and the base in the installation process of some large mechanical equipment.

Thirdly, it plays a role in transmitting power. For example, the original rotary motion is changed into the form of linear motion, which is driven by human power through the screw vice drive, and the screw and nut sleeve are used as the top lifting parts in the maintenance of railway vehicles, the support of construction works and the lifting of heavy objects in general.

Machining difficulties in ordinary lathe

ordinary lathe processing double line trapezoidal thread technical difficulties in the lathe processing trapezoidal thread, there is a certain degree of technical difficulty, can not be very good to ensure that the surface roughness of the thread, the labor intensity, and technical skills requirements are also very high, the operator needs to have a high level of technical skills.

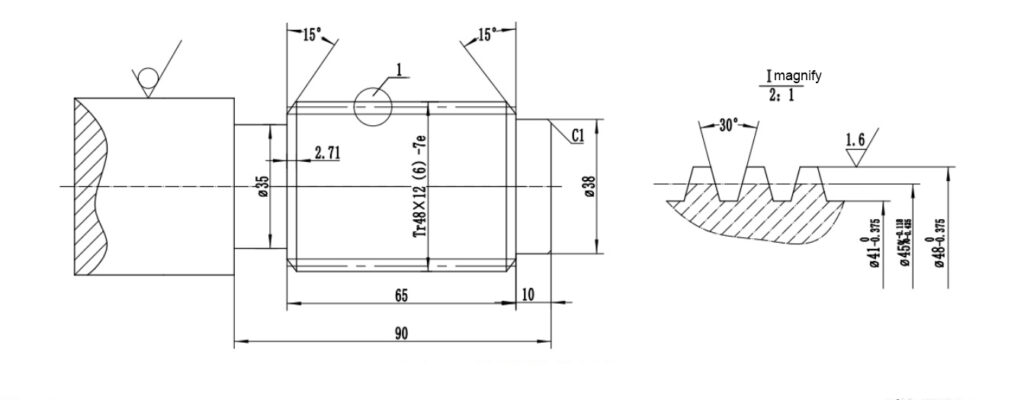

With the use of CNC lathe processing double-line trapezoidal thread, general technicians can master and learn the method of processing double-line trapezoidal thread while ensuring a high degree of processing accuracy. Double-line trapezoidal thread parts are shown in Figure 1. Ordinary lathe processing there are five difficulties:

(1) In the process of machining double thread trapezoidal thread, there will be tool wear, the need for tool replacement, tool change process, the tool needs to be re-calibrated positioning, positioning inaccuracy will lead to threads occurring messy teeth phenomenon.

(2) Ordinary lathe turning double thread trapezoidal thread is realized through the screw drive, the movement of the tool holder to the chuck process there is the influence of the transmission chain error, the machining process is difficult to ensure that the double thread trapezoidal thread of the lead and pitch of the high precision.

(3) Using an ordinary lathe to process double thread trapezoidal thread, in this process, after turning into the first thread, it is necessary to move a pitch through the tool holder on the lathe; the moving distance needs to use the percentage meter or the small scale plate of the tool holder on the lathe, to make the tip of the lathe tool move along the axis accurately by the distance of one pitch, the whole process, divided into two threads to be processed.

(4) Some old lathe due to use for a long time, lathe operation error and gear wear makes the gear mesh phase offset, need to constantly adjust the gear mesh phase in the machining process, to ensure the quality of machining better.

(5) In the process of machining, the draft of turning double thread trapezoidal thread is adjusted by the operator, and there will be machining errors in this process, which makes it difficult to guarantee the quality of machining.

CNC lathe processing double line trapezoidal thread method

CNC lathe machining double line trapezoidal thread is a relatively complex but important process, the key lies in the reasonable choice of processing methods.

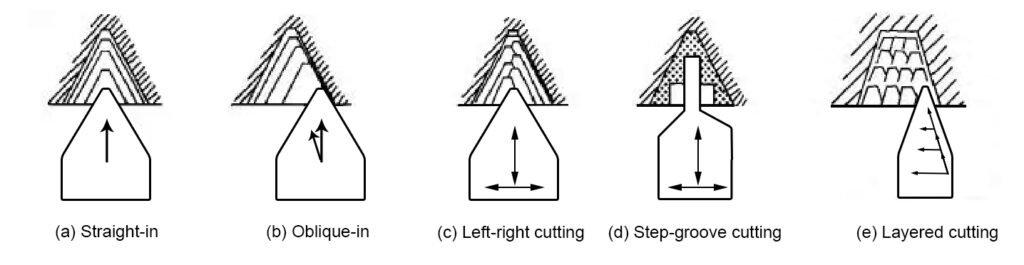

There are many methods for turning trapezoidal threads, generally there are two kinds of single-tool and multi-tool completion. Double thread trapezoidal thread machining method is shown in Figure 2.

1. Analyze the G32 straight method

Format: X(U)_Z(W)___R__F.

With the straight-in cutting method, G32 applies to tapered threads. This thread machining instruction applies to machining straight threads, tapered threads, and end threads, and the program is complicated, so it is generally not chosen.

2. Analysis G92 Straight-in method

Format: X(U)Z(W)__R__F.

In the forward cutting method, the thread turning tool X directions intermittently feeds until the depth of the teeth is reached. Using this method of processing trapezoidal threads, thread turning tool three surfaces have to participate in cutting, which leads to chip removal difficulties, so that the tool wears faster, the amount of tool eaten is too large, prone to the phenomenon of “knife”, this method is not desirable.

3. Analyze G76 oblique method

Format: G76 P(m)(a)Q(dmin)__R(d).

g76 x(u)z(w)__p(k)__q(d)__f(l).

In the inclined feed method, the thread-turning tool feeds intermittently to the depth of the tooth along the direction of the tooth type. With this method of thread cutting, the thread turning tool always has only one side cutting edge to participate in cutting so that the chip removal is relatively smooth and the phenomenon of “sticking” does not easily occur.

4. Analyzing G78 left and right feed method

Format: G78 P(m)(a)__Q(dmin)__R(d)__D1;

G78 X(U)ZW)__P(k)__Q(d)__F(l).

Compared with the G32 instruction and the G92 instruction, the disadvantage of both is that it is difficult to remove chips during the machining process, which leads to fast tool wear and even prone to the phenomenon of “tool stabbing”.

Comparing the first two with G76 instruction, the first two do not have the advantages of G76, G76 instruction is easy to program, so that scholars can easily learn to program, and at the same time, it can also be very good to ensure the quality of machining and requirements.

The program format of G76 instruction and G78 instruction is similar; their instruction format is relatively simple, the calculation is not cumbersome, convenient and quick, and suitable for manual programming in thread processing.

Double-line trapezoidal thread machining process analysis and process

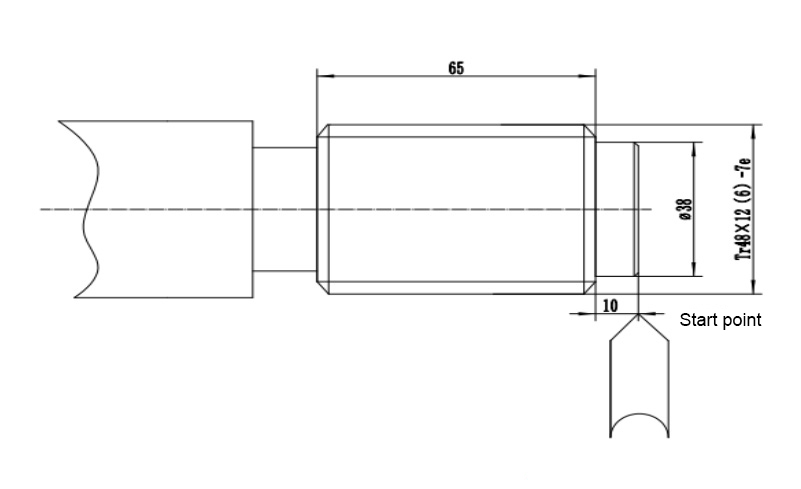

This paper shows the Frank CNC system FANUC-oiMF type CNC lathe, processing as shown in Figure 3 trapezoidal thread Tr48 × 12 (6)-7e, and process analysis and processing analysis.

As shown in Figure 1, double line trapezoidal thread length of 65 mm, chamfer for 30 °, thread surface roughness of Ra1.6, the requirements of the mechanical movement relationship to meet the transmission needs, the thread mechanism can rotate flexibly, so the whole should have a certain degree of rigidity requirements, so the double line trapezoidal threaded parts selection of 45 steel.

1. Calculate the dimensions of double thread trapezoidal threads

The most important thing in trapezoidal thread processing is the size calculation. Only correctly grasp the trapezoidal thread of the relationship between the large diameter, diameter, and diameter and correctly calculate their respective sizes to make a qualified double thread trapezoidal thread. Through the analysis of the parts in Figure 1, it is known that the double thread trapezoidal thread Tr48×12(6)-7e, the nominal diameter of the thread D = 48 mm, thread lead L = 12 mm, thread pitch P = 6 mm, the number of thread heads n = 2, after consulting books, it is known that the outer trapezoidal thread formula is as follows The thread pitch P=6 mm, the number of threads n=2 after consulting the books to learn the external trapezoidal thread calculation formula is as follows:

Trapezoidal thread diameter: D = nominal diameter (1)

According to the formula (1), the large diameter of the trapezoidal thread in Figure 1 is 48 mm, and according to the tolerance code, check the tolerance table of code in the Machinery Manual to know that the upper deviation of the size is 0 mm, and the lower deviation is -0.375 mm.

Trapezoidal thread height: h = 0.5 × P + AC (2)

According to the formula (2) and consult the books, AC = 0.5 mm, calculated Figure 1 double line trapezoidal thread height: h = 0.5 × 6 + 0.5 = 3.5 mm.

Trapezoidal thread diameter: d1 = diameter -2 × height (3)

Calculate the diameter of the trapezoidal thread of Fig. 1 according to equation (3): d1=48-2×3.5=48-7=41 mm.

According to the tolerance code, consult the mechanical manual code tolerance table to know the size of the upper deviation of 0 mm and the lower deviation of -0.375 mm.

Trapezoidal thread center diameter: d2 = D-0.5P (4)

According to the formula (4), the center diameter of the trapezoidal thread in Figure 1 is calculated as follows: d2=48-0.5×6=48-3=45 mm.

According to the tolerance code, consult the mechanical manual code tolerance table to know the size of the upper deviation of -0.118 mm and the lower deviation of -0.425 mm.

Trapezoidal thread bottom width: W = 0.366P-0.536 × AC (5)

According to the formula (5) to calculate Figure 1, double line trapezoidal thread bottom width: W = 0.366 × 6 – 0.536 × 0.5 = 1.928 mm.

Trapezoidal thread tooth top width: F = 0.634P (6)

Calculate the width of the top of the trapezoidal thread in Fig. 1 according to equation (6): F=0.634×6=3.804 mm.

2. Selection of tool for machining double-thread trapezoidal threads

It is essential to choose the right tool for machining trapezoidal threads. Choosing the right tool can significantly improve the productivity and the quality of double-thread trapezoidal threads. This paper uses the processing of steel 45 as an example. In the processing trapezoidal thread of steel 45, the tool with YT5 hardened white steel cutter and coated carbide cutter is used more. When choosing YT5 hardened white steel cutter, the blade may be clamped due to the error of manual sharpening angle and bouncing due to the hardness of machining No.45 steel, affecting the precision and quality. One should choose coated carbide tools to grasp better the accuracy, quality, and surface roughness of double-thread trapezoidal thread processing.

Double-line trapezoidal thread program design and methods

There are various programming methods for double-thread trapezoidal threads, which can be automatically and manually programmed. These are usually encountered in thread fixed cycle instructions G32 and G92, thread composite cycle instructions G76 and G78, and other machining instructions.

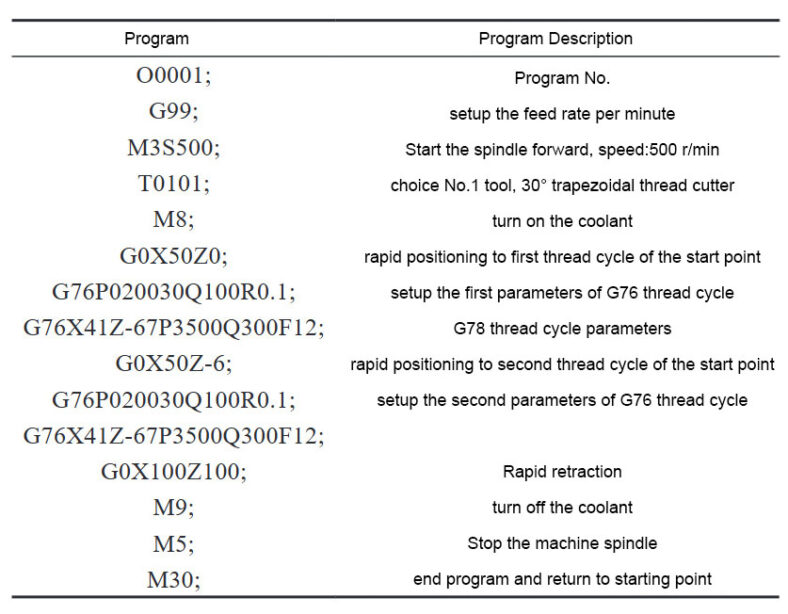

The two-thread trapezoidal thread program is designed as follows:

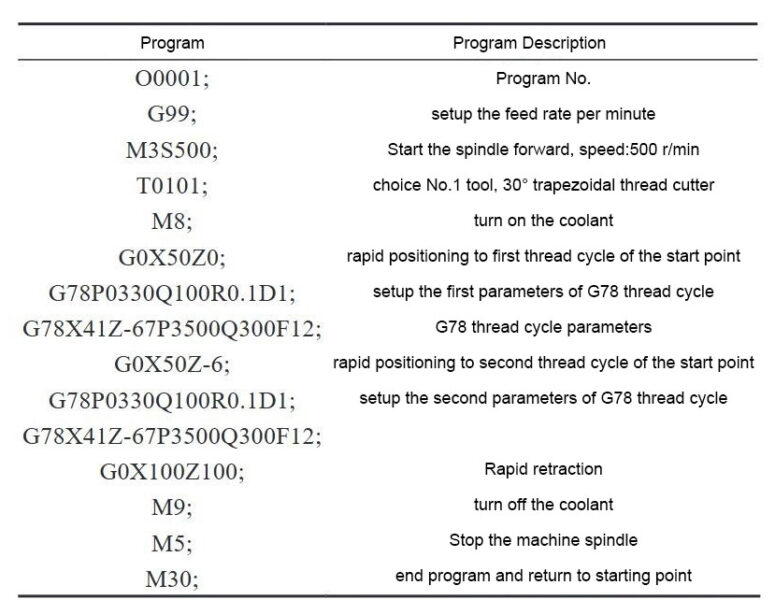

The following is a program comparison between the G78 and G76 thread-cutting compound cycle instructions. The starting point of programming is set at the origin of the workpiece (X-axis is on the axis of the part, and Z-axis is the right end face of the part), and the FANUC-oiMF CNC lathe system is used to process the part with double-threaded trapezoidal threads (the part with double-threaded trapezoidal threads is shown in Fig. 1). The contents of the program for machining double-threaded trapezoidal threads by the G76 instruction and the description of the program are shown in Table 1, and that of the G78 instruction is shown in Table 2. The program and program description of the G76 instruction for machining double threads are shown in Table 1, and the contents of the G78 instruction for machining double threads are shown in Table 2.

As we can see, G76 and G78 instructions are similar in program format. Their instruction format is simpler, the calculation is not cumbersome, it is convenient and fast, suitable for manual programming of thread machining, and it is also the most commonly used two kinds of instructions in the field of thread machining, the G76 thread cyclic instruction is applied more for processing ordinary thread, and the G78 thread cyclic instruction is applied more for processing trapezoidal thread. The G78 instruction optimizes the feed method under the G76 instruction. The G78 instruction optimizes the feed method under the G76 instruction, and it can be said that G78 is an enhanced version of the thread machining instruction.

Control points of double-line trapezoidal thread machining

(1) Before running the thread cycle program, make sure that the parts and tools are clamped and stabilized on the CNC lathe, and make sure that the workpiece or tool does not loosen or fall during the machining process, because the second clamping is not allowed before the end of the thread machining, or else it will produce the threads messy teeth.

(2) before processing, to ensure that the lathe spindle speed is normal, the processing process shall not change the spindle speed of the CNC lathe and can not adjust the spindle speed of the CNC lathe multiplier. Otherwise, it will produce chaotic teeth and thread lines.

(3) Because of the trapezoidal thread of Fig. 1, the precision of each dimension is required to be high, so the metric micrometer gauge should be correctly selected to measure to ensure the precision of each dimension of the double line trapezoidal thread.

(4) G78 is the most commonly used thread cycle instruction for CNC lathe machining of double-thread trapezoidal thread. The difference between G76 and G78 is that G76 is a one-sided feed method. At the same time, G78 is a left-right feed method, so G78 is more suitable for the processing of multiple threads and trapezoidal threads of screw and worm, so G78 is more often used in the field of CNC machining of trapezoidal threads. Therefore, the G78 instruction is used more in CNC trapezoidal thread machining.

(5) In CNC machining, CNC lathe processing double thread trapezoidal thread is more advantageous than ordinary lathe machining, which makes it difficult to ensure accuracy and produces more error factors. CNC lathe processing not only reduces the fatigue intensity of labor but also greatly reduces the error and improves the product quality and production efficiency of double thread trapezoidal thread.

Conclusion

In summary, this paper analyzes the processing method of double-thread trapezoidal thread, compares the processing of several instructions, compares the fixed cycle instruction and the compound cycle machining instruction, and finally adopts the left and right feed method of the G78 thread cycle cutting instruction for CNC turning. Compared with other instructions, this method is simple to calculate and does not easily produce the phenomenon of a “knife.” Combined with the actual practice, after the practical test, this machining method can improve the production efficiency and meet the quality requirements of the parts.