Mig vs Tig welding: Similarities and Differences

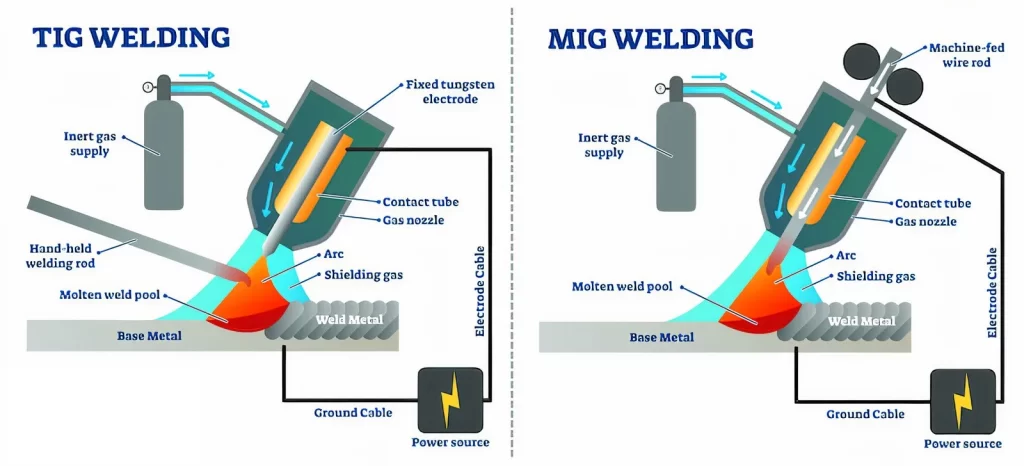

MIG and TIG welding are two popular welding methods that share similarities, such as utilizing an electric arc and a shielding gas. However, there are distinct differences, particularly in the type of welding electrodes employed to establish the arc. MIG utilizes a continuous, machine-fed solid wire (consumable wire electrode), while TIG employs a non-consumable electrode and a hand-held filler rod for welding.

These differences translate into unique strengths, weaknesses, and preferred applications for both MIG and TIG welding processes. To gain a deeper understanding, let’s delve into an exploration of these two welding techniques.

What is MIG welding?

MIG welding, also called wire welding or gas metal arc welding (GMAW), uses a constant voltage power supply to create an electric arc between a continuous feeding solid wire and the base metal. The electric arc melts the wire and sticks it to the base metal, creating a weld pool. At the same time, an inert shielding gas, like argon or carbon dioxide, is sent to protect the weld pool from atmospheric contamination. This protective gas is why the welding is called “metal inert gas” or MIG welding.

MIG welding is super fast, making it awesome for big projects like metal gates. It’s easy to learn, and the welds don’t need much cleaning or finishing. But if you need really precise and super clean welds, another type called TIG welding might be better.

What is TIG welding?

TIG welding, formally known as Tungsten Inert Gas welding or Gas Tungsten Arc Welding (GTAW), is a precise welding process that employs a tungsten electrode to create an electric arc. This arc generates the necessary heat to melt and fuse the metals being joined. Unlike MIG welding, TIG welding does not typically use a continuous feed of filler material from a wire. Instead, the filler material, if needed, is added manually by the TIG welder through a separate filler rod.

During this process, an inert gas, typically argon or helium, is used to shield the welding area from atmospheric contamination, ensuring a clean and reliable weld.

TIG welding is highly regarded for its ability to produce intricate, high-quality welds that meet rigorous standards. It finds extensive application in industries where precision, strength, and a flawless finish are paramount, such as aerospace, automotive, and art fabrication. However, TIG welding operates at a slower pace compared to other welding techniques and necessitates a skilled welder to achieve optimal results.

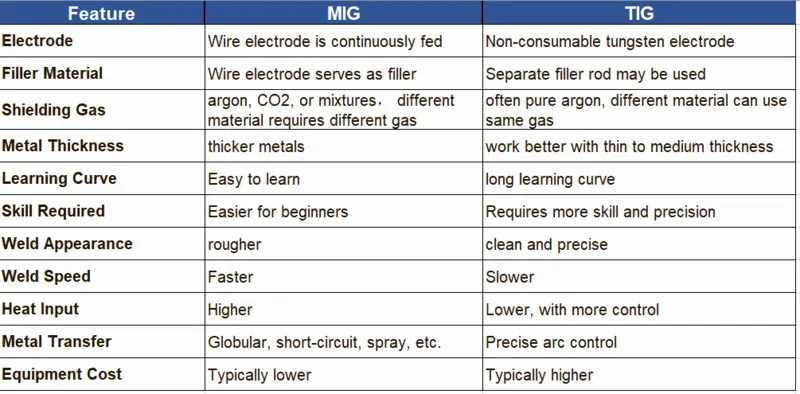

MIG vs TIG Welding Brief Comparison

This is a brief version of the differences between Mig and Tig welding.

Mig vs Tig welding key differences

Below are the key differences between Mig welding and Tig welding.

Weld Strength

Mig weld strength is good, Tig is better.

In MIG (Metal Inert Gas) welding, the weld strength is generally considered to be good and suitable for a wide range of applications. The continuous and efficient deposition of filler material through the feeding wire results in a strong and durable weld. However, the weld strength in MIG welding can be slightly lower compared to TIG welding due to potential issues such as porosity or inclusions that can occur with the rapid deposition of filler material.

Conversely, TIG(Tungsten Inert Gas) welding is renowned for producing exceptionally strong welds. The precise control over the welding process and the ability to manually add the filler material using a separate rod allow for meticulous and controlled welds. This level of precision contributes to superior weld strength in TIG welding, making it a preferred choice for critical applications where weld quality and strength are paramount, such as aerospace and nuclear industries.

Weld Speed

Mig is fast, Tig is slow.

The MIG welding process is known for its efficiency and speed. The continuous feeding of the filler wire allows for a rapid welding process. The automated nature of the wire feed and the ability to achieve long, uninterrupted welds make MIG welding significantly faster compared to TIG welding. This speed is especially advantageous for projects that require high productivity and shorter lead times.

On the other hand, the TIG welding process operates at a slower pace. The need for precise control and manual addition of filler material using a separate rod results in a more meticulous and time-consuming process. While TIG welding may not match the speed of MIG welding, its strength lies in its precision and ability to create high-quality welds, making it ideal for applications where speed is not the primary concern.

Shielding Gas

Mig uses a CO2 and argon mixture, Tig uses pure argon or helium.

MIG and TIG welding use shielding gases to prevent unwanted chemical reactions with the air. In MIG welding, a mix of inert gases like argon and carbon shields the weld pool, with the gas mixture varying based on the material being welded. In TIG welding, pure argon or helium is used to shield the weld pool. Tig welding can use the same inert gas for different materials.

For MIG welding, the wire feeding device needs adjustment based on the welding material, whether it’s a soft or hard metal wire. In contrast, TIG welding uses hand-fed filler rods. Thus, setting up TIG welding is relatively simpler compared to MIG welding.

Weld Aesthetics

Tig looks better.

MIG welding, with its continuous wire feed and relatively higher deposition rates, tends to produce welds with a slightly rougher appearance. The speed and efficiency of MIG welding can result in weld beads that may require additional finishing or smoothing for a cleaner look. However, with proper technique and adjustment, MIG welding can still achieve satisfactory aesthetics, making it suitable for various applications.

On the other hand, TIG welding is known for its exceptional control and precision, resulting in welds with superior aesthetics. The ability to manually add filler material using a separate rod allows for fine-tuning and precise shaping of the weld bead. This control often leads to smooth, neat, and visually appealing welds. TIG welding is a preferred choice for applications where the appearance of the weld is a crucial consideration.

Power Supply

Mig uses DC, Tig uses AC and DC depends on the metal welded.

MIG welding primarily employs a constant voltage power supply (DC). This means that the voltage remains stable during the welding process. The welding machine adjusts the wire feed speed to regulate the current, maintaining a consistent arc. This setup simplifies the welding process, making it easier for the MIG welder to focus on other aspects of welding.

On the other hand, TIG welding utilizes both constant current and constant voltage power supplies. In direct current (DC) TIG welding, the current remains steady while the voltage can vary. In alternating current (AC) TIG welding, the current changes direction periodically, providing versatility for welding different materials. The choice of power supply depends on the welding requirements, including the type of metal and the desired welding outcome. AC allows for a cleaning action on the surface of the metal, helping to remove oxides, contaminants, and impurities during the welding process. This cleaning action results from the alternating current changing its direction, breaking down the oxide layer, and producing a smoother, cleaner weld. This cleaning action is particularly important for metals easy to oxide such as Aluminum or Magnesium.

Difficulty to Learn

Mig is easy, Tig needs more training.

MIG welding is generally considered easier to learn and master compared to TIG welding. The continuous wire feed in MIG welding simplifies the process, making it more approachable for beginners. With minimal manual dexterity required for filler rod control, individuals can quickly grasp the basics and produce satisfactory welds in a relatively short time.

Conversely, TIG welding is regarded as more challenging to learn due to its intricacy and demand for precise technique. It requires good manual coordination to control the tig torch, filler rod, and foot pedal simultaneously. Achieving mastery in TIG welding, especially in terms of creating high-quality welds, demands a steeper learning curve and extensive practice.

Which welding is better suited for what metals

Steel

MIG welding is often more suitable for welding steel due to its efficiency, ease of use, and compatibility with steel welding applications. MIG welding allows for a continuous wire feed, making it ideal for welding steel structures, automotive parts, and similar steel components. The welding of most steels does not require high appearance requirements because they are either protected by coatings or uncoated but have low appearance requirements. This is another reason why most people use MIG welding on steel.

Stainless Steel

For welding stainless steel, both MIG and TIG welding are commonly used and can be suitable depending on the specific requirements of the project.

MIG welding is often preferred for welding stainless steel due to its efficiency and speed. The continuous wire feed in MIG welding allows for faster welding and higher deposition rates. It is suitable for thicker sections of stainless steel and is efficient for projects that require a higher volume of welding.

On the other hand, TIG welding is excellent for welding stainless steel when precision and control are essential. TIG welding provides better control over the heat input and allows for precise welding, making it suitable for thinner sections of stainless steel and applications where the appearance of the weld is crucial.

Aluminum

Tig is more suitable for welding aluminum alloys and magnesium alloys. Around 1940, Tig welding became famous because it could better weld these two light metals.

Aluminum possesses a high thermal conductivity and low melting point compared to other metals. TIG welding allows precise control over the heat input, crucial for welding aluminum effectively. The TIG welder can adjust the heat to match the high thermal conductivity of aluminum, ensuring proper fusion without overheating or warping the metal.

TIG welding offers a narrow and well-controlled heat-affected zone (HAZ). The ability to focus the heat precisely on the welding area minimizes the HAZ, reducing the risk of thermal distortion or metallurgical changes in the surrounding material, a critical advantage when welding aluminum.

TIG welding produces clean, spatter-free welds, which is essential for aluminum welding where impurities or contaminants can compromise the weld quality.

Aluminum alloy components often demand a superior appearance, and TIG welding excels in meeting these aesthetic criteria, particularly in weld quality.

Two Different Metals

TIG welding is often the choice for welding two different metals. The reason is that different metals conduct heat differently, so precise heat control is essential during welding. TIG welding allows the use of various welding wires, making it easier and more convenient when welding two different metals together.

When To Use MIG vs TIG Welding

When to Use MIG Welding:

Thicker Materials: MIG welding is the go-to choice when working with thicker materials, providing efficient and strong joints in such scenarios.

Long Runs: Continuous wire feeding in MIG welding makes it optimal for extended welding runs, minimizing interruptions to replace filler material. This ensures a smoother welding process, reducing the possibility of weld defects, and making it ideal for long, uninterrupted runs. And it saves a lot of time.

Handling Difficult Positions: MIG welding stands out for its ease of use even in challenging positions, requiring only one hand for operation. This convenience in difficult welding positions enhances its applicability.

High Productivity Demands: MIG welding’s ability to maintain a swift pace of work makes it suitable for high-productivity requirements, making it the preferred choice in industrial settings where speed is crucial.

Suitable for Less Experienced Welders: MIG welding is relatively easier to learn and master, making it accessible and efficient for less experienced welders or those new to the welding process.

When to Use TIG Welding:

Thinner Materials: TIG welding’s precision and control make it perfect for welding thin materials, where preventing burn-through or warping is crucial for a successful weld. This process ensures delicate and accurate welding in such cases.

Short Runs: TIG welding is most effective for shorter runs, providing meticulous welds in a precise and controlled manner, particularly beneficial for projects requiring careful attention to detail in limited welding lengths.

Shop or Bench Work: TIG welding excels in controlled environments like workshops or benches, where the TIG welder can maintain a stable position, resulting in superior welds. The stability contributes to achieving the desired welding outcome.

Delicate or Fine Work: TIG welding is the preferred choice when aesthetics matter, delivering visually appealing welds. Projects involving visible components, like automotive restoration or artwork, benefit from TIG welding, ensuring a refined appearance without warping or burning issues.

Non-ferrous Metals: Experienced welders often opt for TIG welding when working with non-ferrous metals like aluminum, copper, and stainless steel due to its precise control and suitability for these exotic materials, ensuring top-notch weld quality and appearance.

Experienced Welders for Optimal Results: TIG welding’s advantages fully come to fruition under the guidance of experienced welders who can harness its precision. For intricate projects and desired superior outcomes, having an experienced welder is paramount to making the most of TIG welding. In cases where expertise is lacking, a simpler method like MIG welding may be a more suitable choice.

One comment

Leave a Comment

You must be logged in to post a comment.

Keep up the fantastic work!