Rapid Plastic Prototypes: An Overview of Manufacturing Technologies and Materials

Rapid plastic prototypes are important tools for making new products because they let engineers and designers make physical copies of their ideas. These rapid prototypes are used to test how they look, how well they fit, and how well they work. They are also used to test the manufacturing process and materials.

Manufacturing Technologies for Plastic Prototypes

Plastic rapid prototypes can be made using a number of different manufacturing methods, each of which has its own pros and cons. Three of the most popular methods are injection molding, 3D printing, and CNC machining.

Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process for creating plastic parts. The process involves injecting molten plastic material into a mold cavity, where it cools and solidifies into the desired shape.

Injection molding is ideal for producing high-volume, high-precision parts with excellent surface finishes. It is also an efficient process, with cycle times ranging from a few seconds to a few minutes.

Pros of plastic injection molding

Versatility

Plastic injection molding can produce a wide range of products in different shapes and sizes, from simple parts to complex components with intricate details.

Efficiency

Injection molding is a highly automated process that can produce a large number of parts quickly and consistently. The cycle time can be as short as a few seconds, which makes it a cost-effective method for large production runs.

Quality

Injection molded parts have a high level of accuracy and consistency, which ensures that the final products meet the desired specifications.

Customization

Injection molding allows for the customization of parts with various colors, textures, and finishes, which can help companies create unique products that stand out in the market.

Sustainability

Injection molding can be a sustainable manufacturing method because it uses only the necessary amount of plastic to create the parts, and the waste material can be recycled or reused.

Cons of plastic injection molding

High initial cost

The initial cost of creating the mold for plastic injection can be high, especially for complex parts. This can be a barrier for small businesses or startups that don’t have the financial resources to invest in the tooling.

Lead time

Creating the mold for injection can take several weeks or months, which can increase the lead time for the final product. This may not be suitable for industries with fast-changing market demands.

Material limitations

Injection molding can only use certain types of plastic resin materials, which may not be suitable for all applications. Some plastics may not be able to withstand high temperatures or have other limitations.

Environmental impact

Although plastic injection molding can be a sustainable manufacturing method, the plastic waste remains an environmental concern. The waste generated from the manufacturing process can pollute the environment if not handled properly.

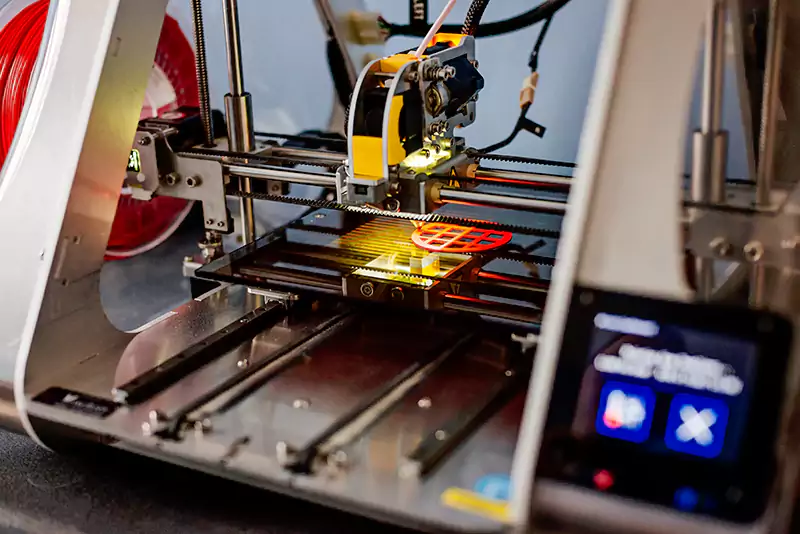

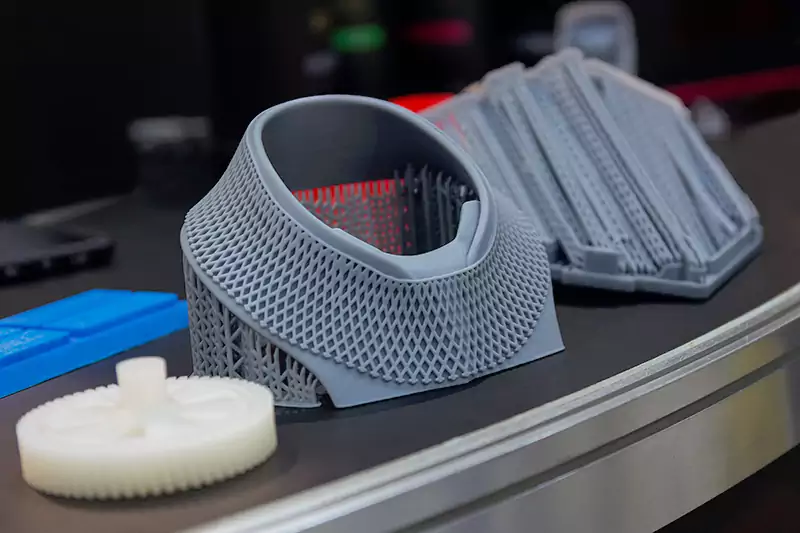

3D Printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering material on top of itself. There are several types of 3D printing technologies available, including Fused Deposition Modeling (FDM), Stereolithography Appearance (SLA), and Selective Laser Sintering (SLS).

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is a popular 3D printing technology used in plastic prototyping. It works by melting and extruding thermoplastic filament, which is then deposited layer by layer to create the desired object. The filament is melted using a heated extrusion nozzle and deposited on a build platform that moves in the X, Y, and Z axes.

FDM is a cost-effective and fast prototyping method that allows for a wide range of plastic materials to be used, including ABS, PLA, PETG, and Nylon. Additionally, FDM allows for the creation of complex geometries and internal cavities, making it ideal for functional prototyping and small-batch production.

However, the surface finish of FDM prototypes may not be as smooth as injection-molded parts, and the layer-by-layer deposition process can lead to weak points and reduced mechanical strength.

Stereolithography Appearance

SLA technology, fully known as Stereolithography Appearance, is to focus the laser on the surface of the light-cured material (Photosensitive resin) so that it can solidify from point to line, from line to the surface in order, and repeat, so as to form a three-dimensional solid layer by layer.

Laser curing molding is the earliest rapid prototyping manufacturing process, which has high maturity and has passed the test of time. The rapid prototypes is directly made from the CAD digital model, with fast processing speed, a short production cycle, and no need for cutting tools and molds. It can process rapid prototypes and molds with complex structures and shapes or is difficult to form by traditional means. It is the most popular industrialized 3D printing technology, and hence extremely low cost for single plastic rapid prototypes making.

Because this process requires photosensitive resin, the material selection is limited. Its product strength is far lower than that of injection molding or CNC products of similar materials. The color is also affected by the availability of materials.

Pros of 3D printing

Customization

3D printing enables the creation of highly customized and personalized products that can be tailored to meet the specific requirements of customers.

Rapid prototyping

3D printing allows the creation of prototypes in a matter of hours, which can save time and money. It is the most common way for rapid prototyping especially for outlook verification prototypes.

Reduced waste

3D printing uses only the necessary amount of material to build an object, reducing waste and promoting sustainability.

Accessibility

3D printing has become increasingly accessible and affordable, with many companies producing affordable 3D printers for personal use.

Cons of 3D printing

Limited material selection

While there are many materials that can be used for 3D printing, the selection is still limited compared to traditional manufacturing methods.

Complexity

3D printing can be complex and requires technical knowledge and expertise to operate the equipment and software effectively.

Size and tolerance limitations

Most 3D printers have size limitations, meaning that larger objects may not be able to be printed. Among all 3 common plastic prototyping methods, 3D printing is the worst in terms of tolerance control. It also has the least reserlution, some fine thread features can not be realized by 3D printing.

Cost

While 3D printing can be cost-effective for small runs or prototyping, the cost can become prohibitively high for larger production runs.

CNC Plastic prototypes

Using CNC machines to make plastic prototypes.

The strength of 3D printing products is generally poor, and most materials are not resistant to high temperatures. The range of materials available is also limited. It is not necessarily suitable for the sample used to test the function. CNC processing does not have these problems. The materials used for CNC processing are injection molded blocks or plastic profiles with high strength. Almost all plastic materials have square or rod materials. CNC prototyping got a wide selection of materials. The initial investment of injection molding is large, the cycle is long, and the mold needs to be made, so it is only applicable to the samples with large quantities or unlikely to be changed. CNC is applicable to batch production from a single piece to thousands or even tens of thousands of pieces. It takes relatively less time, same as 3D printing it is one of the most popular method of rapid prototyping. CNC plastic prototyping also offers the highest tolerance among all 3 prototyping methods.

CNC plastic prototyping also has its limitations. Generally, most plastic products will adopt injection molding, rotational molding, blow molding, and other mass production methods after the products are finalized. Due to the difference between CNC and injection molding, the design of CNC products will be very different from that of injection molding products. Therefore, the sample verification of CNC can not fully reflect the performance of the later injection molding products. At the same time, many complex designs that can be realized by injection molding or 3D printing cannot be realized by CNC machining.

Although CNC is suitable for both single-piece production and mass production, 3D printing is usually much cheaper in a few to dozens of batches. In tens of thousands to hundreds of thousands of batches, injection molding, rotational molding, and other processes are usually much cheaper than CNC.

Functional Testing of Plastic Prototypes

Functional testing is a critical aspect of developing plastic prototypes. It is essential to ensure that the prototype can meet the desired performance requirements before proceeding to mass production. The functional testing process involves subjecting the prototype to various testing conditions to determine its performance under different scenarios.

One common method of functional testing is known as the Design of Experiments (DOE). DOE involves varying several parameters to determine their impact on the prototype’s performance. The DOE approach enables engineers to optimize the prototype’s design, material selection, and processing parameters to achieve the best performance.

Another approach is to use Finite Element Analysis (FEA) to simulate the prototype’s performance under different conditions. FEA enables engineers to analyze and optimize the prototype’s structural integrity, stiffness, and other mechanical properties.

Plastic Materials for Prototyping

Plastic materials offer a wide range of benefits for prototyping. They are easy to process, lightweight, and can be molded into complex shapes. Some of the most commonly used plastic materials for prototyping include:

ABS (Acrylonitrile Butadiene Styrene)

ABS is a popular choice for prototyping due to its excellent impact resistance and toughness. It is widely used in the automotive, consumer goods, and electronics industries.

Polycarbonate (PC)

Polycarbonate is a highly transparent and durable plastic material. It is commonly used in applications where impact resistance and high clarity are required, such as medical devices and automotive parts. The most well known PC product is probably DVD, CD and VCD.

Polypropylene (PP)

Polypropylene is a lightweight and versatile plastic material. It is commonly used in prototyping for consumer goods, packaging, and automotive applications.

Nylon

Nylon is a strong and durable plastic material that is commonly used in prototyping for mechanical parts and components.

POM

POM has high strength and certain self-lubrication. It is often used to make structural parts, gears, and other parts requiring high strength.

How to Choose Your Plastic Material?

Choosing the right plastic material for your prototyping project is crucial as it can impact the overall quality and functionality of your prototype. Here are some factors to consider when selecting the right plastic for your project:

Purpose

The intended purpose of your prototype should be considered when selecting a plastic material. For instance, if your prototype needs to be flexible, you might want to consider materials such as polyethylene or polypropylene. If your prototype requires strength and durability, materials such as polycarbonate or ABS might be better suited.

Temperature resistance

Consider the temperature requirements of your project. Some plastic materials can withstand high temperatures, while others may not. For instance, if your prototype will be used in high-temperature environments, you might want to consider materials such as PEEK or PEI.

Chemical resistance

The plastic material you choose should be resistant to the chemicals that it will be exposed to. For instance, if your prototype will come into contact with harsh chemicals, materials such as PVC or PTFE might be better suited.

Cost

The cost of the material is also a crucial factor to consider. Some materials are more expensive than others. It is important to consider the cost of the material relative to your budget and the overall cost of the project.

Availability

It is important to consider the availability of the plastic material you choose. Some materials might not be readily available, which can impact the lead time and overall cost of your project.

Conclusion

Plastic rapid prototypes play a critical role in the product development process. They allow engineers to test and refine product designs before proceeding to mass production. Injection molding and 3D printing are two of the most popular manufacturing technologies for producing plastic prototypes, while functional testing enables engineers to optimize the prototype’s performance.

Selecting a suitable plastic material for prototyping is also crucial to ensure that the prototype can meet the desired performance requirements. Overall, plastic rapid prototyping has become an essential part of modern product development, and it is expected to continue to evolve as new technologies emerge.