Powder Coat Finish: A Solid and Artistic Cover

Know About Powder Coat Finish

Powder coat finish is a dry finishing process used to add a protective and decorative coating to a wide range of surfaces, such as metal, plastic, and wood. The process involves electrostatically charging a dry powder material, which is then sprayed onto the surface to be coated. The charged powder particles adhere to the surface, forming a uniform and durable coating that is resistant to corrosion, impact, and abrasion. The powder-coated parts or surfaces are then cured in an oven, where the powder particles melt and fuse into a smooth and seamless finish.

Powder coat finish is widely used in various industries, including automotive, construction, furniture, and appliances, due to its superior performance, versatility, and environmental friendliness.

Brief History of Powder Coat Finishes

The history of powder coat finish can be traced back to the 1940s when a group of scientists discovered that they could electrostatically charge and spray dry paint powders onto metal surfaces. However, it was not until the 1960s that the first commercial powder coating system was introduced, which was primarily used in the automotive industry.

In the following decades, advancements in powder coating technology, materials, and equipment have led to the widespread adoption of the powder coating industry and coat finish in various industries, including aerospace, electronics, and medical equipment. Today, powder coat finish is a popular alternative to conventional liquid coatings due to its superior performance, durability, and environmental benefits.

How Powder Coating Process Works

Surface Preparation

The first step in the powder coating process is to prepare the surface to be coated. This involves cleaning and pre-treating the surface to remove any oil, dirt, rust, or other contaminants that may interfere with the adhesion of the powder coating. The surface is then dried and heated to remove any moisture and ensure optimal adhesion before coating the powder.

Powder application

The second step is the application of the powder material. The powder material is typically made of thermosetting resins, pigments, and additives that provide the desired properties, such as durability, corrosion resistance, and color.

The powder is electrostatically charged using a spray gun and is then sprayed onto the surface to be coated, where it adheres uniformly due to the electrostatic attraction.

Curing

The third and final step is the curing of the powder coating. The coated surface is then placed in an oven or curing chamber, where it is heated to a specific temperature and held for a specific period of time to melt and fuse the powder particles together. The result is a durable, high-quality, and uniform finish that is resistant to impact, abrasion, and corrosion.

Materials Used in Powder Coating process

The materials used in the powder coating process are composed of three main components: resins, pigments, and additives. The resins are responsible for providing the powder coating its mechanical properties, while the pigments give it its color and aesthetic properties. The additives are added to improve the coating’s application properties, such as flow, leveling, and curing.

Some of the most common resins used in the powder coating process include:

Epoxy

Epoxy resins provide good adhesion, durability, and chemical resistance. Epoxy-coated surfaces are known for being hard and electrically insulative. However, they tend to become brittle over time, especially when exposed to UV light, which is present in sunlight.

As a result, epoxy-coated items are primarily used indoors or buried underground as pipe coatings to avoid the negative effects of UV light.

Polyester

Polyester resins are known for their durability, weather resistance, and gloss retention. They are often used in outdoor applications, such as architectural metalwork and automotive parts.

Polyurethane

Polyurethane resins provide excellent durability, flexibility, and abrasion resistance. They are often used in applications that require high performance and impact resistance, such as automotive components and sports equipment.

Acrylic

Acrylics have an advantage over epoxy-based resins in that they perform well under sunlight and blend well over a surface. They leave a high gloss, wet-looking finish that can either be clear or pigmented. However, despite their popularity, their use as automobile clear-coats is still being developed due to their brittleness and lack of durability. Nevertheless, acrylics are widely used on specific automotive parts, such as wheels and exposed engine parts, when a super gloss finish is desired.

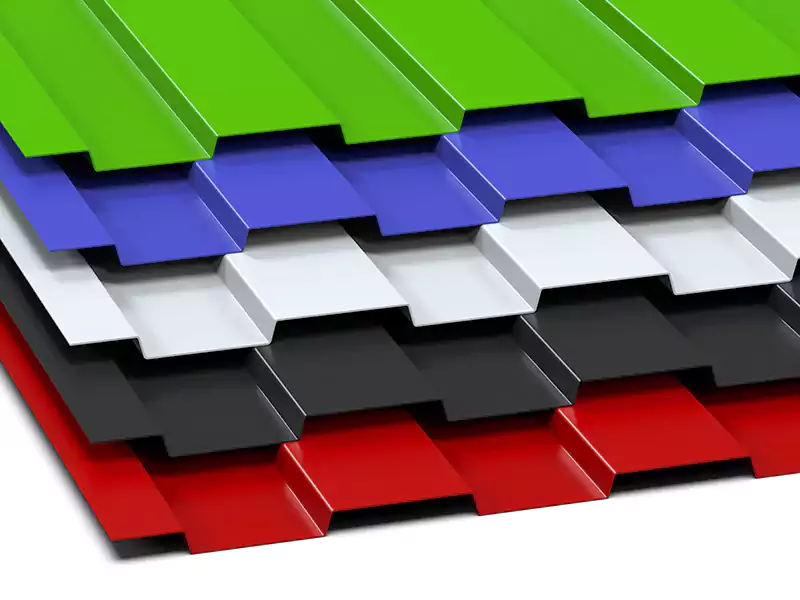

The pigments used in the powder coating process can be organic or inorganic and may be added to provide a wide range of colors and effects, such as metallic, matte, or textured finishes. The choice of pigment depends on the desired appearance and performance of the finished product.

Powder coating materials may also contain various additives, such as flow agents, leveling agents, and curing agents. These additives are added to improve the powder’s application and curing properties.

Applications of Powder Coat Finish

Powder coating is a versatile and durable finishing method that is used in a wide range of applications. Here are some common applications of the powder coating method:

Automotive Industry

Powder coating is used extensively in the automotive industry for finishing wheels, frames, suspension parts, engine components, and more. The durable finish and aesthetic versatility make it an ideal choice for automotive applications.

Architectural Applications

Powder coating is commonly used in architectural applications, such as doors, windows, and building facades. The durability and weather resistance of powder coating makes it an ideal choice for outdoor architectural applications.

Furniture and Home Decor

Powder coating is also used in the furniture and home decor industry for finishing metal furniture, lighting fixtures, and other decorative items. The range of colors and finishes available make it a popular choice for designers.

Industrial Applications

Powder coating is used in many industrial applications, such as machinery, equipment, and pipelines. The durability and chemical resistance of the finish makes it ideal for industrial environments.

Consumer Electronics

Powder coating is used in the consumer electronics industry for finishing products like computer cases, gaming consoles, and other electronic devices. The finish is durable, scratch resistant, and can be applied in a variety of colors and textures.

Medical Industry

Powder coating is used in the medical industry for finishing medical devices and equipment. The finish is durable, easy to clean, and can be applied in a variety of colors and textures.

Advantages of Powder Coat Finish

Powder coat finish offers several advantages over other finishing methods. Some outstanding advantages are as followed:

Durability and longevity

Powder coatings are highly durable and long-lasting. They are resistant to scratches, chipping, and fading, making them ideal for high-traffic or outdoor applications.

Environmental friendliness

Powder coating is an eco-friendly finishing method. The process produces little to no volatile organic compounds (VOCs) and generates minimal waste. Additionally, unused powder coating materials can be reclaimed and reused, reducing waste even further.

Cost-Effectiveness

Powder coating is a cost-effective finishing method. The curing process is efficient and produces minimal waste, reducing material and labor costs. Additionally, the durability of the finish reduces maintenance and replacement costs over time.

Aesthetics and Varieties

Powder coating offers a wide range of colors, textures, and finishes, allowing for endless design possibilities. Additionally, the powder coat finish can be applied to a variety of materials, including metal, plastic, and wood.

Application efficiency

Powder coating is a quick and efficient process that allows for high-volume production. The powder can be applied in a single pass, reducing production time and costs.

Types of Powder Coating

According to different materials and applications, the types of powder coating vary correspondingly. There are some common types of power coasting:

Thermosetting powder coating

This is the most commonly used type of powder coating. It involves using a powder that cures when heated, creating a durable and long-lasting finish. Thermosetting powder coating is ideal for applications where durability and resistance to weather and chemicals are important.

Thermoplastic powder coating

Unlike thermosetting powder coating, thermoplastic powder coating can be re-melted and re-coated. This makes it a good option for applications where rework or repairs may be needed.

UV-Cured powder coating

This type of powder coating cures quickly under UV light, making it a fast and efficient option for certain applications. It is often used in the electronics and medical industries.

Maintenance and Care for Powder Coat Finish

Powder coat finish is known for its durability and longevity, but proper maintenance and care are still necessary to ensure the finish lasts as long as possible. Here are some tips for maintaining and caring for a powder coat finish:

Regular cleaning

Regular cleaning is essential to maintaining the appearance and durability of the powder coat finish. Use mild detergent and water to clean the surface regularly, especially in high-traffic or outdoor areas.

Avoid abrasive cleaners

Avoid using abrasive cleaners, solvents, or harsh chemicals on powder-coated surfaces, as they can damage the finish. Instead, use a soft cloth or sponge to gently clean the surface.

Prevent scratches and chips

Prevent scratches and chips on the surface by avoiding rough or abrasive contact with the finish. Use furniture pads, coasters, or other protective measures to prevent damage.

Touch-Up as needed

Touch up any chips or scratches as soon as they are noticed to prevent further damage. Use touch-up paint specifically designed for powder coatings.

Protect from UV exposure

The powder coatings can fade over time when exposed to UV rays, especially when the coating pigment is organic. Protect the surface from direct sunlight, especially in outdoor applications, by using shade structures or UV-resistant coatings.

Inspect regularly

Inspect the surface regularly for signs of damage or wear. Address any issues as soon as they are noticed to prevent further damage.

Conclusion

In conclusion, powder coat finish is a durable, versatile, and environmentally friendly finishing method that offers a wide range of benefits for various applications. With its excellent durability, chemical resistance, and aesthetic versatility, it has become a popular choice for manufacturers, designers, and consumers alike. Additionally, its cost-effectiveness and environmental friendliness make it a sustainable and responsible option.

Proper maintenance and care are necessary to ensure the longevity of the finish, but with regular cleaning and protection from UV exposure, the powder coatings can last for many years. Overall, a powder coat finish is an excellent choice for anyone looking for a durable, high-quality finishing solution for their products or projects.

Capable Machining has applied the Powder coating process to thousands of parts for different applications. If you have any questions about this surface finishing process, please send us an email, and we will be glad to answer.