Stainless Steel: Why It Is Stainless and Its Types

The term “stainless steel” is commonly used as a general term, but in actuality, there are multiple variations of stainless steel, each with unique applications. It is an alloy made by combining various base metals, resulting in a material that is significantly stronger than its individual components. This applies to all alloys, including stainless steel.

What Is Stainless Steel?

Stainless steel is an iron-based alloy that possesses remarkable resistance to rusting and corrosion due to its high chromium content of at least 11%. Other elements such as carbon, nonmetals, and metals may be added to the alloy to achieve specific desired properties. The presence of chromium in stainless steel results in the formation of a passive film that acts as a protective layer, allowing the material to self-heal in the presence of oxygen.

The excellent properties of this steel, including its corrosion resistance and luster, make it an ideal material for a wide range of applications. It can be shaped into sheets, plates, bars, wires, and tubing for use in various industries, including cookware, cutlery, surgical instruments, major appliances, vehicles, large buildings’ construction material, industrial equipment such as those found in paper mills, chemical plants, water treatment facilities, and storage tanks and tankers for chemicals and food products.

History

The practice of experimenting with metal alloys dates back thousands of years, with evidence of iron smelting dating as far back as 1800 B.C. Crucible steel, on the other hand, was first introduced around 300 B.C.

Stainless steel was discovered by Harry Brearley in Sheffield, England in 1913. Harry Brearley was a metallurgist, he was trying to create erosion-resistant steel when accidentally find that additional chrome in carbon steel could enhance corrosion resistance. The alloy was called “rustless steel” and later changed to “stainless steel”. The first stainless steel containers a 0.24 % C, and 12.8% Cr.

Over time, engineers have continued to experiment with this steel, resulting in a highly versatile material. By incorporating or eliminating certain metals, they have been able to create various types of stainless steel, each with unique properties and applications. This has led to the use of this steel in a vast array of products, ranging from kitchen utensils to construction components, and even simple items.

Composition

This steel is a type of steel that contains at least 10.5% chromium, along with varying amounts of other elements such as nickel, carbon, manganese, and molybdenum. The exact composition of stainless steel can vary depending on the intended use and required properties, but generally, it contains the following elements:

Chromium (Cr)

Chromium is the most important element in stainless steel, as it provides the steel sheet with its corrosion resistance. The amount of chromium in stainless steel can range from 10.5% to as high as 30%.

Nickel (Ni)

Nickel is often added to stainless steel to improve its ductility and toughness, and to increase its resistance to corrosion. The amount of nickel in the steel can range from 2% to as high as 30%.

Carbon (C)

Carbon is added to the steel to improve its strength and hardness. However, too much carbon can reduce the steel’s corrosion resistance. The amount of carbon in stainless steel is usually less than 0.08%.

Manganese (Mn)

Manganese is added to stainless steel to improve its strength and ductility. The amount of manganese in stainless steel is usually less than 2%.

Molybdenum (Mo)

Molybdenum is added to some types of this steel to increase their resistance to corrosion, especially in harsh environments. The amount of molybdenum in stainless steel can range from 0.2% to 6%.

Other elements that may be present in smaller amounts in the steel include silicon, nitrogen, phosphorus, sulfur, and copper.

What Makes Stainless Steel Stainless?

Stainless steel is known for its high resistance to corrosion and staining, which is what makes it “stainless.” The key element that gives stainless steel its corrosion-resistant properties is chromium.

When chromium is added to steel, it reacts with oxygen in the air to form a thin, invisible layer of chromium oxide on the surface of the steel. This layer is extremely thin, only a few atoms thick, but it is highly protective. It acts as a barrier, preventing water, oxygen, and other corrosive substances from reaching the underlying steel.

In addition to chromium, other elements such as nickel, molybdenum, and nitrogen can also be added to stainless steel to enhance its corrosion resistance and other properties.

Overall, it is the presence of chromium, and other alloying elements, that makes the steel stainless by forming a protective layer on the surface of the steel that prevents corrosion and staining.

Properties

Stainless steel is a highly versatile material with a range of properties that make it useful for a wide variety of applications. Some of its key properties include:

Corrosion Resistance

It is highly resistant to corrosion and rust, making it suitable for use in harsh environments, such as marine and chemical processing applications. This resistance is due to the presence of chromium, which forms a passive oxide layer on the surface of the steel that prevents further oxidation and corrosion.

Strength and Durability

This steel is an incredibly strong and durable material, making it ideal for use in heavy-duty applications that require high levels of strength and resistance to wear and tear.

Heat Resistance

This steel has excellent heat resistance, making it suitable for use in high-temperature environments. This property is due to the presence of chromium, which forms a protective oxide layer on a steel surface that can withstand high temperatures without degrading.

Hygienic Properties

These steels are easy to clean and sanitize, making them suitable for use in applications where hygiene is critical, such as food processing and medical equipment.

Aesthetic Appeal

It has a sleek and modern appearance that makes it a popular choice for use in architectural and design applications.

Types

There are several types of this steel, each with its own unique properties and characteristics. The four main types of stainless steel are:

Austenitic Stainless Steels

This is the most commonly used type of stainless steel, accounting for approximately 70% of all stainless steel production. Austenitic steel is non-magnetic, highly corrosion-resistant, and has excellent formability and weldability.

– Strength: Austenitic stainless steels are typically known for their good ductility, toughness, and excellent corrosion resistance, but they have relatively lower strength compared to other stainless steel types.

– Heat treatment: Austenitic stainless steels are not heat-treatable, but they can be cold-worked to improve their strength and hardness.

– Content: Austenitic stainless steels contain high levels of nickel and chromium, and often some molybdenum, nitrogen, and other elements.

– Typical alloys: Examples include 304, 316, and 321 stainless steel.

Ferritic Stainless Steels

Ferritic stainless steel is magnetic and has a lower carbon content than austenitic stainless steel. It is highly resistant to stress corrosion cracking, making it suitable for use in high-temperature applications. However, it has lower toughness and is less ductile than austenitic stainless steel.

– Strength: Ferritic stainless steels have moderate strength levels, but they are less ductile than austenitic stainless steels. They are known for their excellent corrosion resistance, particularly in high-temperature applications.

– Heat treatment: Ferritic stainless steels are not typically heat treated to improve their mechanical properties, as they are relatively soft and ductile in their annealed condition. However, ferritic stainless steels can be heat treated in some cases to improve their machinability and to relieve stresses from cold working. The most common heat treatment used for ferritic steel is annealing, which involves heating the steel to a high temperature and then cooling it slowly. This process can improve the ductility and toughness of the steel, making it easier to work with. Ferritic stainless steels can also be solution annealed to improve their formability, but they are not typically hardened by heat treatment as they cannot be transformed from austenite to martensite like other this steel types.

– Content: Ferritic stainless steels contain high levels of chromium and often small amounts of other elements like molybdenum, titanium, and aluminum.

– Typical alloys: Examples include 409 and 430.

Martensitic Stainless Steels

Martensitic stainless steel is magnetic and has a higher carbon content than austenitic or ferritic stainless steel. It is highly resistant to corrosion and is often used in applications where high strength and hardness are required, such as cutlery and surgical instruments.

– Strength: Martensitic stainless steels are known for their high strength and hardness, but they have lower toughness compared to other stainless steel types. They are also more susceptible to corrosion compared to other types of stainless steel.

– Heat treatment: Martensitic stainless steels are heat treatable and can be hardened and strengthened by heat treatment processes like quenching and tempering.

– Content: Martensitic stainless steels contain high levels of carbon and often lower levels of nickel and chromium compared to other stainless steel types.

– Typical alloys: Examples include 410 and 420 stainless steel.

Duplex Stainless Steels

Duplex stainless steel is a combination of austenitic and ferritic stainless steel. It has excellent corrosion resistance and high strength, making it suitable for use in harsh environments such as marine and chemical processing applications. However, it can be more difficult to weld than other types of steel.

– Strength: Duplex stainless steels have high strength levels, typically higher than austenitic or ferritic stainless steels, and they have good ductility and toughness. They are also known for their excellent corrosion resistance.

– Heat treatment: Duplex stainless steels are typically not heat treated for hardening purposes, as they already exhibit high strength levels and good toughness in their annealed condition. However, duplex stainless steels can be heat treated to improve their corrosion resistance, and machinability, and to relieve stresses from cold working. The most common heat treatment used for duplex steels is solution annealing followed by quenching, which involves heating the steel to a high temperature (typically between 1050-1150°C) and then rapidly cooling it in water or air. This process can improve the steel’s ductility, toughness, and corrosion resistance.

Duplex stainless steels can also be annealed at lower temperatures (780-850°C) to improve their formability and to relieve stresses from cold working. Additionally, duplex teels can be aged at intermediate temperatures (between 475-550°C) to improve their mechanical properties and corrosion resistance, a process known as secondary hardening.

– Content: Duplex stainless steels contain high levels of both chromium and nickel and often smaller amounts of other elements like molybdenum and nitrogen.

– Typical alloys: Examples include 2205 and 2507.

Overall, the type chosen for a particular application will depend on factors such as the desired properties, the intended use, and the environment in which it will be used.

Applications of Stainless Steel

Architecture and Construction

It is widely used in the construction of modern buildings due to its durability, corrosion resistance, and aesthetic appeal. It can be used for everything from structural components to decorative finishes and cladding.

Kitchenware and Appliances

It is a popular choice for kitchenware and appliances due to its hygienic properties, ease of cleaning, and resistance to corrosion and staining. It is used in everything from cutlery and cookware to refrigerators and dishwashers.

Medical Equipment

Stainless steel is widely used in the medical industry due to its biocompatibility, corrosion resistance, and ease of cleaning and sterilization. It is used in everything from surgical instruments and implants to medical equipment and diagnostic tools.

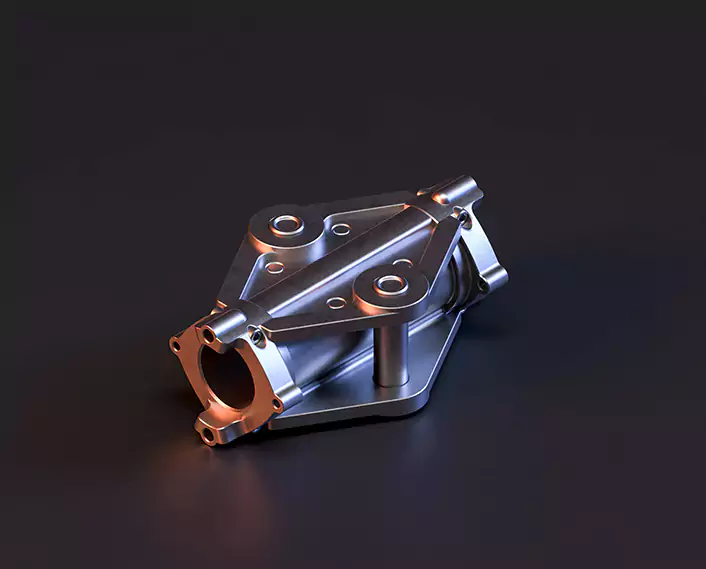

Automotive and Aerospace

It is used in the automotive and aerospace industries due to its strength, durability, and resistance to corrosion and high temperatures. It is used in everything from exhaust systems and engine components to aircraft frames and aerospace structures.

Oil and Gas

It is used extensively in the oil and gas industry due to its resistance to corrosion and high temperatures. It is used in everything from pipelines and storage tanks to drilling equipment and offshore platforms.

Future of Stainless Steels

The future of stainless steel looks bright, with continued growth expected in various industries that rely on this material. Here are a few trends that are likely to shape the future of stainless steel:

Sustainability

The growing focus on sustainability and environmental concerns is expected to drive demand for high-quality stainless steel, which is highly recyclable and has a long lifespan.

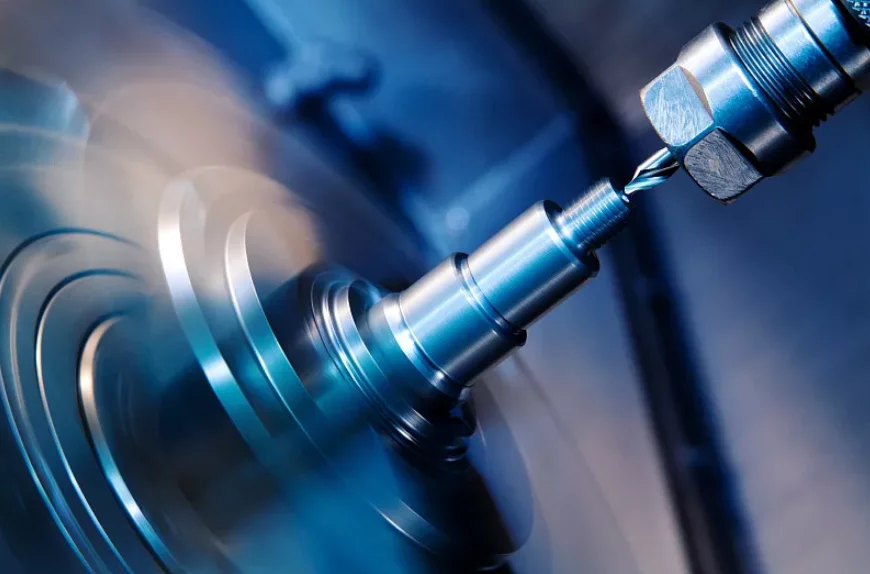

Advanced Manufacturing Techniques

The development of advanced manufacturing techniques such as 3D printing is expected to increase the design possibilities and production efficiency of the steel products.

New Applications

With continued research and development, new applications for stainless steel are likely to emerge, especially in the fields of medicine, electronics, and renewable energy.

High-performance Alloys

The development of new high-performance this steel alloys with improved properties such as increased strength, durability, and corrosion resistance is expected to drive demand in various industries.

Surface Treatment Technologies

New surface treatment technologies are expected to emerge, improving the appearance and durability of products.

Conclusion

In conclusion, it is a remarkable material that has a wide range of applications across various industries. Its unique properties, including resistance to corrosion, durability, and ease of maintenance, make it a popular choice for many applications, from architecture and construction to medical equipment and automotive components.

With continued research and development, the future of stainless steel looks promising, with new applications, alloys, and surface treatment technologies likely to emerge. Stainless steel’s sustainability and recyclability make it an attractive choice for companies looking for more environmentally friendly materials.

Overall, CapableMachining said stainless steel’s versatility, durability, and resistance to corrosion make it an essential material for a wide range of applications, and it is expected to remain a popular choice for many years to come.