Technology development trend of five-axis CNC machine tools

CNC machine tools are the workhorses of the manufacturing equipment industry, is the cornerstone of the realization of advanced manufacturing technology and equipment modernization, is to ensure the development of high-tech industries and the modernization of national defense and military strategic equipment. With the development of industrialization five-axis linkage CNC machine tool is considered to be the aerospace, marine, precision instruments, power generation and other industries processing key components of the most important processing tools.

As the most difficult and widely used CNC machine tool technology, five-axis linkage CNC machine tools have their irreplaceable advantages in processing.

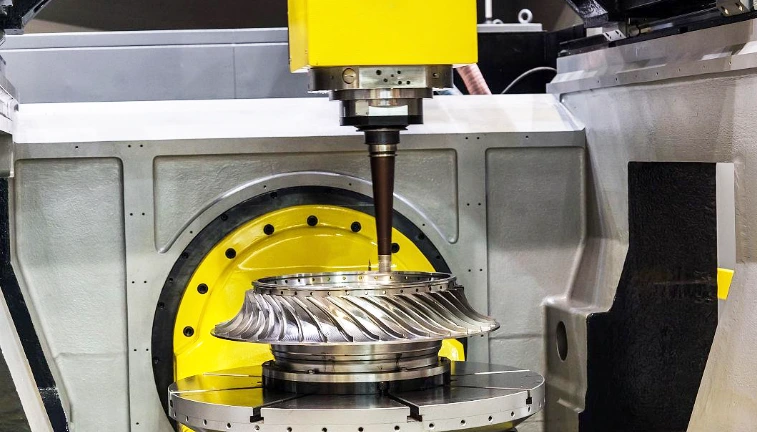

1) able to process general three-axis linkage machine tools can not process or can not be a clamping processing completed continuous smooth free-form surfaces. For example, aircraft engine rotor, large generator rotor, large ship spiral prize.

Due to five-axis CNC machine tools in the processing of tool angle relative to the workpiece can be adjusted at any time to avoid tool processing interference, so five-axis CNC machine tools can complete three-axis linkage machine tools can not be completed many complex processing.

2) can improve the machining accuracy of free space surface machining efficiency and machining quality. Relative to three-axis CNC machine tool processing general cavity complex workpieces, five-axis CNC machine tools can be completed in a clamping processing, and because of the five-axis CNC machine tool processing can be adjusted at any time the angle of the position, five-axis CNC machine tools can be processed at a better angle of the workpiece, avoiding the multiple clamping, greatly improving the processing efficiency, processing quality and machining accuracy.

3) In line with the trend of machine tool development. In the parts processing, a lot of time is consumed in the handling of workpieces, loading and unloading, installation and adjustment time, in order to minimize these times, people want to use a machine tool to complete as much processing.

Five-axis CNC machine tools can complete several sets of three-axis CNC machine tools to complete the processing tasks, greatly saving space and workpiece running between different processing unit time and cost. Five-axis CNC machine tools play an important role in the development of today’s machine tool industry has become a hot spot and focus.

Five-axis linked CNC machine tools in various countries

1. The basic structure of five-axis linkage CNC machine tools to achieve five-axis linkage

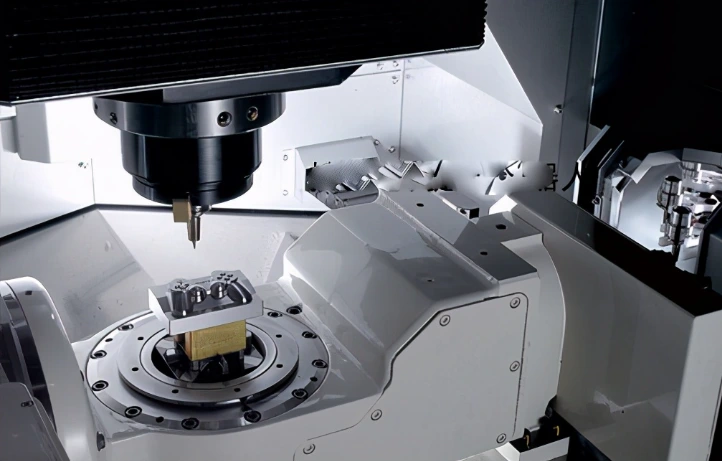

The basic structure of five-axis linkage CNC machine tools to achieve five-axis linkage. In addition to realizing the movement of the X/Y/Z axes, five-axis linkage CNC machine tools also need to realize the rotation of two axes. Taking the vertical machining center as an example, there are two ways to realize the rotation head of the vertical five-axis machining center:

1) Table slewing axis.

The table set on the bed can rotate around the X-axis, defined as the A-axis. In the center of the table, there is also a rotary table that rotates around the Z-axis, defined as the C-axis. By combining the A-axis and the C-axis, the workpiece fixed on the table can be machined by the spindle of the machining center except for the bottom surface.

The advantage of this setup is that the spindle is relatively simple, spindle rigidity is good, low manufacturing costs, the disadvantage is that the table can not be set too large, less load-bearing.

2) Relying on the rotary spindle head.

The front of the spindle is a rotary head, this rotary head on the one hand can be rotated around the Z-axis 360 °, to become the C-axis, on the other hand can be rotated around the X-axis, to become the A-axis. The advantage of this setup is that the spindle head is more flexible and can machine large parts such as the fuselage of a large airliner, so it is more widely used on large gantry machines.

Because of this setup in the cutting process makes the spindle relative to the workpiece turned over an angle, so that the spherical milling cutter to avoid the apex of the cutting, to ensure a certain linear speed, can improve the surface cutting accuracy, so this structure is very welcome by the high-precision surface machining.

In addition to the above two structures in addition to horizontal machining centers have through the combination of table rotation and spindle head swing to achieve the five-axis linkage structure.

2. Research status of five-axis linkage CNC machine tools in Europe and the United States

The current five-axis linkage CNC machine tools in Europe and the United States, Japan as a representative of the five-axis linkage CNC machine tools in these countries represent the highest level of development of five-axis linkage CNC machine tools.

At present the famous machine tool factory five-axis linkage CNC machine tool technology development focus can be summarized as: high speed, high precision, environmental protection, intelligence, composite. Torque motor in foreign countries as a rotary coordinate drive device is widely used, so that foreign machine tool feeding mechanism to achieve high-speed, low-loss, high-precision, high-efficiency target IS.

DMG’s DMC165, when equipped with a rotary table, is capable of five-axis simultaneous CNC machining.

The maximum speed of the machine can reach 30,000 r/min, due to the use of high-performance linear motor drive, its fastest movement can reach 90m/min, acceleration 28.

As a representative of the composite machine tools, Germany DMG’s GMX250 linear five-axis milling and turning center and DMU80P/H five-axis milling and turning center, South Korea Doosan PUMAMX2500ST nine-axis control of the five-axis milling and turning center Switzerland, Willem C. Makoder W-508MT eight-axis control of the five-axis linkage milling and turning center Switzerland, Bumotec’s S192b, the first of its kind in the world. The S192b1 and S191FrL-R five-axis milling and turning centers exhibited by Baume & Mercier Technology, Switzerland, also gained wide attention at CIMT2007.

The use of new machine tool technology in five-axis machine tools has made five-axis machine tools simpler and simpler in structure, but more and more excellent in performance and functionality.

Recently, in order to avoid the fork spindle head in the spindle occurs a small deflection, the C-axis must be rotated by a large angle of the situation, the German Zimmermann company designed a M3ABC spindle head, this spindle head adds a curved guideway, and therefore more than one B coordinate.

Therefore, it is a head with three rotary coordinates A, B and C. In addition to the limitation of the offset angle of about plus or minus 40°, there are other positional limitations. This milling head combines all the advantages of the various construction solutions to date.

The advantages are as follows: very good rigidity and compactness with A, B and C coordinates; large deflection range; and unrestricted c-axis rotation. This design allows 5-axis CNC machines to be machined with higher precision.

3. China’s five-axis linkage CNC machine tool research status quo

China’s five-axis linkage CNC machine tools relative to the overall level of foreign countries is still relatively low, specifically in the key functions can not independently develop or similar products with foreign countries than the stability, accuracy and other differences.

But in the support of relevant state policies and related enterprises, schools and other departments of the efforts of China’s five-axis CNC machine tool technology has also been rapid development, and gradually formed a more mature products.

From the CIMT2007 exhibition of machine tools, China’s five-axis CNC machine tools have formed a variety of mature technology, with independent technology and intellectual property rights of the characteristics of IS].

Shenyang Machine Tool exhibited VMC25100u 5-axis vertical machining center and GMC1230u 5-axis gantry high-speed machining center, which are suitable for the machining of Chin alloy and aluminum alloy frames in the aviation industry, and have been relying on imports from Europe and the United States for a long time.

Jinan machine tool display XHSV2525X6000 five-axis gantry mobile high-speed milling machining center, table size of 6,000 mmx2500mm, X / Y / Z-axis stroke of 6,000 mm/2,500mm/1250mm, feed speed 0 ~ 20,000mm/min, fast into the 40m/min, swing milling spindle 0 ~ 24 The oscillating rotary milling spindle 0~24000r/min, power 40kw, tool magazine capacity 20.

This product is the largest five-axis linkage machining centers in the current exhibition specifications, indicating that China’s research and development in high-grade large-scale, heavy-duty CNC machine tools has also made the latest progress.

During the “Tenth Five-Year Plan” period, China’s five-axis CNC machine tools in the development of certain results can be summarized in five points.

1) Some original achievements have been made.

There are two machine tool group in Qiqihar, Tsinghua University, Harbin Electric Machinery Co., Ltd. developed XNZD2415 large gantry type five-axis linkage mixed machine tools in China parallel five-axis linkage CNC machine tools made an important breakthrough, and in the Harbin Electric Machinery Factory water plant two years of use in the higher evaluation.

2) five-axis CNC machine tool technology innovation has made a breakthrough.

For example, two machine tools in Qiqihar independently developed high-speed five-axis CNC milling machine, through the introduction and digestion of technology, mastered the milling head within the oil mist cooling beam pre-stress anti-deformation control and other key technologies, and the use of harmonic drive principle, the development of the A/C pendulum angle milling head, to meet the precision requirements of the processing of large-scale water pump blade surface.

Shenyang Machine Tool Group through joint design with foreign countries to overcome the power drive unit, large diameter and large through-hole high-speed spindle tool holder, thermal balance, precision compensation and other key technologies, high-performance milling and turning composite machine tool magazine and robotic tool changer completely with independent intellectual property rights.

The maximum spindle speed is 70,000r/min, which can meet the high speed and high efficiency machining of large rotating parts with complex shapes, such as the spindle of aircraft engine and the piston of landing gear marine engine.

Beijing Mechanical and Electrical Institute of High Technology Co., Ltd. has developed a series of 5-axis blade machining centers for Dongfang Steam Turbine Factory. On the basis of the research of large blade machining process, it has given the solution method of optimal cutter center distance, and designed a new type of clearance elimination mechanism and mechanism balancing system for rotary axis, and put forward the free combination of springs, which has made the balancing effect reach 80%.

3) Functional components research and development to speed up the pace.

Beijing Machine Tool Research Institute developed the electric spindle and separation drive type high-speed spindle unit, as well as Luoyang Bearing Research Institute developed a variety of internal mounted electric spindle unit, so that China’s high-speed spindle unit technology is becoming more mature.

Tsinghua University has made important achievements in the research of linear servo motor, and its high response linear motor and high thrust linear motor servo system have the advantages of stable and reliable special power supply.

In the control system, build high thrust permanent magnet linear AC motor all-digital servo drive control hardware and software platform, servo control has also made great breakthroughs; through independent innovation and technical cooperation with domestic and foreign.

At present, China has a number of machine tool manufacturers have mastered the A/C axis composite pendulum milling head design and manufacturing technology, the development of different structures of the five-axis linkage CNC machine tools, Beijing Machinery and Electronics Institute of High-Tech Co., Ltd. has also developed a torque motor directly driven by the A/C axis composite pendulum milling head.

4) CNC rotary table and tool magazine directly driven by force motors are successfully developed.

5) Developed HSK toolholder technology and related products

Through the research and analysis of HSK tooling system, developed the expert knowledge system of UJS HSK tooling system, established the comprehensive experimental performance database of HSK tooling system, developed the technology of HSK tool shanks and related products, and made the developed HSK tooling system reach the technical level of the same kind of imported technical products.

Five-axis linkage CNC machine tool development trend

From the research status of five-axis linkage CNC machine tools in various countries, we can clearly see the development trend of today’s five-axis linkage CNC machine tools:

1) High speed, High efficiency

Modern processing industry, high efficiency, low cost and high quality requirements of Europe, the United States, Japan and other countries are keen on high-speed and even ultra-high-speed machine tool research. With the development of machine tool technology 161 high-speed machine tools, the main functional components of high-speed spindle unit, high-speed feed mechanism, high-performance numerical control and servo systems have been a breakthrough, high-speed machine tools are increasingly wide range of applications, the current linear motor-driven spindle speed of up to 15,000 ~ 100,000r/min, feed moving parts rapid traverse speed of 60 ~ 120m/min. cutting feed speed 60m/min. Cutting feed speed of 60m/min. maximum acceleration of 10g.

2) High Reliability

Five-axis linkage CNC machine tool processing surface is more complex, general requirements for its average trouble-free time of more than 20 000 h, and a variety of alarm and protection measures to reduce losses caused by failure. The average failure-free time of foreign drives can reach 30000h.

3) High Precision

With the development of CAM systems, machine tool machining accuracy has been greatly improved, Japan FANUC company designed an ultra-precision machining machine tool machining accuracy of 0.00 um, its unique reciprocating motion unit, can be ultra-precise microfabrication groove.

4) Composite

With the previous pure pursuit of high-speed spindle and feed mechanism is different, today’s market for personalized requirements are increasingly strong, the delivery date is also shortening, so the five-axis machining centers tend to be more small-scale, and even single-piece production.

In order to meet this requirement, machine tool manufacturers need to develop a higher degree of composite composite machine tools, the above mentioned five-axis mill-turn machining center is an important example of this trend.

5) Intelligent Network Flexible.

Intelligent contained in the various aspects of machine tool control, mainly adaptive control technology fault diagnostic devices, intelligent digital Ho service drives. Network diagnosis, remote control, network design and the rise of technology to make the five-axis linkage CNC machine tools to network development.

6) Greening. Dry cutting or semi-dry cutting technology has been a rapid development, in Europe there have been about 10% to 15% of the processing using dry cutting or semi-dry cutting technology.

Conclusion

Five-axis linkage CNC machine tools have become the most important processing tools in today’s processing industry, with the deepening of industrialization, five-axis linkage CNC machine tools will be used in a wider range of fields.