The development of CNC machine tool fixtures

As we all know, tooling fixture is an important part of the process equipment, is one of the most active factors in the process, and directly affects the quality of the product, production efficiency and processing costs. With the continuous progress of science and technology, CNC machining equipment has developed rapidly, with which the corresponding CNC machine tool fixtures are also constantly developing and changing.

Due to the lack of selection of CNC machine tool fixture system considerations, thus appearing in the advanced machining equipment using relatively backward general-purpose fixtures or special fixtures, so as not to give full play to the effectiveness of such equipment. How to improve the rapid response capability of the fixture to give full play to the CNC machine tools and machining centers of the processing efficiency, is the current fixture design issues faced.

Classification of CNC machine tool fixtures

According to the fixture in different types of production in the general characteristics of machine tool fixtures can be broadly divided into general-purpose fixtures, special fixtures, adjustable fixtures, combined fixtures and assembling fixtures 5 categories.

1. general-purpose fixtures

Has been standardized to process a certain range of different workpiece fixtures, known as the general fixture. Its structure, size has been standardized, and has a certain degree of universality, such as three-jaw chuck, spring chuck, top and chicken heart chuck, indexing head, rotary table, flat vise, V-iron and so on.

General-purpose fixture in the production of a wide range of applications, mainly dispersed in the workshop in the hands of machine tool operators, is an indispensable auxiliary tool of the machine tool.

This kind of fixture is adaptable, can be used to clamp a certain shape and size range of various workpieces. The disadvantage is that the accuracy of the fixture is not high, the productivity is also lower, it is more difficult to clamp the complex shape of the workpiece, so it is generally used in small batch production of a single piece.

Such fixtures play a greater role in the production, but the production of products can not be completely dependent on this type of fixture.

2. Specialized fixtures

Specifically designed and manufactured for a certain process of a workpiece fixture, known as the special fixture.

The advantages of the special fixture is targeted, compact structure, easy to operate quickly. In the product is relatively stable, large batch production, the use of a variety of special fixtures, can obtain high productivity and processing accuracy.

The disadvantage is that the design and production cycle is longer, higher cost, poor generalization.

Specialized fixtures are generally used in mass production. In addition to mass production, small and medium-sized batch production also requires the use of some special fixtures, but in the structural design of specific technical and economic analysis.

Currently in many countries the range of parts processed is not wide, so there are still many companies use special fixtures for work, such as the textile machinery industry wall panels, seat frame parts more than the use of special fixtures.

The industrialized countries, the penetration rate of CNC machine tools has reached more than 70%, the wide range of processing parts, the use of special fixtures far from meeting the requirements of the parts change, so in addition to the production of large quantities, generally less separate use of special fixtures.

3. adjustable fixture

Some components can be adjusted or replaced to adapt to a variety of workpiece processing fixtures, known as adjustable fixtures.

For different types and sizes of workpieces, only need to adjust or replace the original fixture on the individual positioning elements and clamping elements can be used.

Adjustable fixture is a new type of fixture developed for the defects of general-purpose fixtures and special fixtures.

General adjustable fixture and group fixture structure is relatively similar, are in accordance with the appropriate adjustment can be used several times the principle of design.

General adjustable fixture of the general range than the general fixture is greater. Group fixture is a special adjustable fixture, according to the principle of group design and can process similar workpieces.

For the series of stereotyped products, and a certain production batch, group clamping is a more economical and practical type of fixture.

This type of fixture is suitable for a relatively single product, product size and shape of the parts do not change the occasion.

4. Combined fixture

The use of standard combination of components, parts, specifically for a workpiece of a process assembly fixture, known as combination fixture.

Combination fixture is a modular fixture, standard module components with high precision and wear resistance, can be assembled into a variety of fixtures. Fixtures can be disassembled after use, cleaned and left to assemble new fixtures.

Because of the combination of fixtures with a combination, adjustability, contingency and other advantages, so the use of a combination of fixtures can shorten the production preparation cycle, components can be repeated many times, and has the advantage of reducing the number of special fixtures, so the combination of fixtures in a single piece, small batch multi-species production and processing is a more economical fixtures.

But the combination of fixtures exists between the components with more links, fixture stiffness is low, not high precision, assembled into a fixture volume and quality, operation is not as convenient as a special fixture and other shortcomings, therefore, it is only used in CNC machining in the structure of a simple, low-precision requirements, the batch of small parts processing.

5. assembly fixture

With a special standardized, series of assembled parts assembled fixture, known as assembled fixture, its base plate and clamping parts often with small hydraulic cylinders.

It has the advantages of the combination of fixtures, but its accuracy and efficiency than the combination of fixtures, structure is more compact than the combination of fixtures, such fixtures are more suitable for use in the production of larger batches.

Application status quo

At present, the above types of CNC machine tool fixtures are applied, each enterprise according to the characteristics of their own products and demand for different types of fixture systems.

In general, due to production needs, enterprises are often a variety of types of fixtures coexist, just have their own focus.

In general, the use of relatively backward fixture systems on advanced machining equipment, so that it is difficult to give full play to the efficiency of CNC equipment, many enterprises have problems.

The formation of this situation is mainly related to the introduction of a large number of enterprises in the CNC machine tool time is not long, the lack of in-depth research on CNC machine tool fixtures and a unified understanding of the fixtures are often limited to ordinary machine tool fixture mode.

Development trend of CNC machine tool fixtures

Driven by the development of CNC machine tools, machining center machine tools, flexible machining units and flexible manufacturing systems, CNC machine tool fixtures are moving towards the direction of multifunctionality, modularity, high precision, high rigidity, high strength, generalization, rapidity and automation.

1. Multi-functional modular fixture components

Can be used alone can also be used in combination with other components in the use of multifunctional modular unit will further increase the proportion of the body.

Such as the use of a variety of positioning and clamping seat, positioning compression bearing, precision vise and other modular units with positioning, clamping and adjustment of the integrated function, can be used alone, can also be assembled together with several pieces of use.

T-shaped foundation, box can be assembled into a clamping fixture for multiple pieces of work, the use of such fixtures can reduce the machine’s downtime, maximize the play of CNC, machining centers, machine tools, high-efficiency performance.

2. High strength, high rigidity, high precision

In order to improve labor productivity, shorten the processing time of the workpiece, the workpiece processing has been to high-speed, large cutting capacity direction, the process is highly concentrated, the workpiece positioning and clamping to complete the milling, drilling, boring and other multi-process processing.

The size and direction of the cutting force is constantly changing, only in the case of CNC machine tool fixture itself has a high strength and rigidity, in order to meet the machining accuracy of the workpiece.

3. Specialized fixture, combined fixture, group fixture integration

Multifunctionality of modern processing equipment, so that the process is highly concentrated, the workpiece can be completed after a positioning and clamping multi-process processing, which requires a common and can be reused combination of adjustable fixture system.

It is composed of a series of unified, standardized components and components, the use of these components, components assembled into a variety of different forms, different structures, reusable fixtures for single-piece or small and medium-sized batch production.

This fixture system retains a variety of advantages of the combination of fixtures, its assembly with the same simple and reliable as the special fixtures, and adjustable components, retaining the advantages of grouped fixtures.

In order to facilitate the fixture and machine tool positioning connection, fixture matrix has a unified standard positioning connection position, so that the special, combined, group fixtures to the integration, combination of the direction of development to meet the needs of modern machining equipment.

4. Rapid workpiece clamping, automation

In order to shorten the workpiece processing in the auxiliary time, reduce the labor intensity of workers, workpiece clamping, disassembly also need to be mechanized, automated. Workpiece clamping by the original single-function compression parts, fasteners can be adjusted for the development of the module to achieve rapid assembly and fast clamping.

For large batches of some parts of the processing, hydraulic fixtures, pneumatic fixtures can realize the workpiece automation fast clamping.

With the increasingly fierce competition in the market, the speed of product replacement accelerated, the user requires shorter and shorter delivery time, in the type of production products, the proportion of mass production declined, the increase in small and medium-sized batch, CNC machine tool fixtures are also with the continuous development of change.

For small and medium batch production, a form of fixture known as flexible fixture system, because of its high precision, high rigidity, high strength, modularity, generalization and rapidity, etc., more and more accepted by many processing enterprises, and gradually become one of the mainstream of CNC machine tool fixtures.

Flexible fixture system

Flexible fixture system is a combination of flexible fixture units, special fixtures and combination fixtures into a fixture system.

Flexible fixture unit is a new type of fixture components developed on the basis of the combination of fixtures, it not only has a combination of fixtures production preparation cycle is short, the advantages of strong versatility, and the basis of the relative integration, need to be equipped with fewer components, the operation is simpler, and a wider range of use.

It can not only be compatible with the combination of fixtures, but also with the combination of specialized fixtures. Flexible fixture system on the one hand has a combination of fixtures with strong flexibility, with special fixtures targeted, compact structure, easy to operate the advantages of rapid; on the other hand, it overcomes the combination of fixtures with poor rigidity, low precision, quality, and the traditional design and manufacturing of special fixtures with high costs, long cycle and other shortcomings.

Of course, there are some disadvantages of flexible fixture system. For example, due to the high precision of flexible fixture components manufacturing, high requirements for materials, complex processes, while there must be a certain number of components to normal use, so a larger investment.

In addition, because the fixture is made by assembling, so the fixture is more bulky than the specialized fixture.

1. Flexible fixture unit

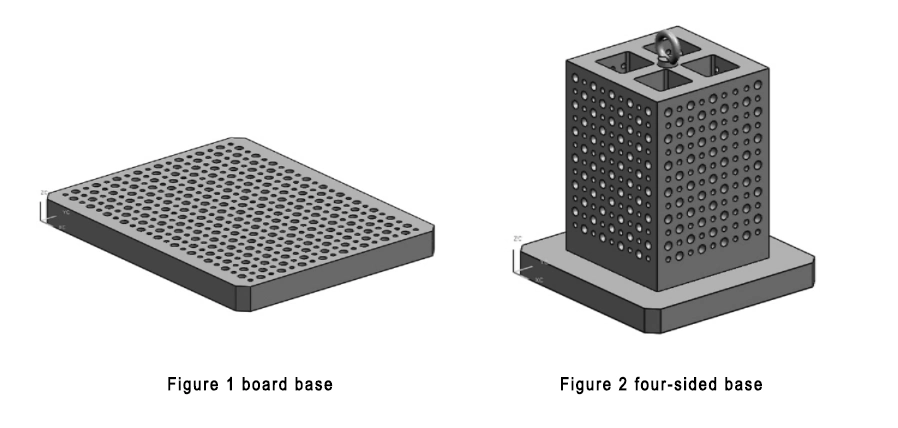

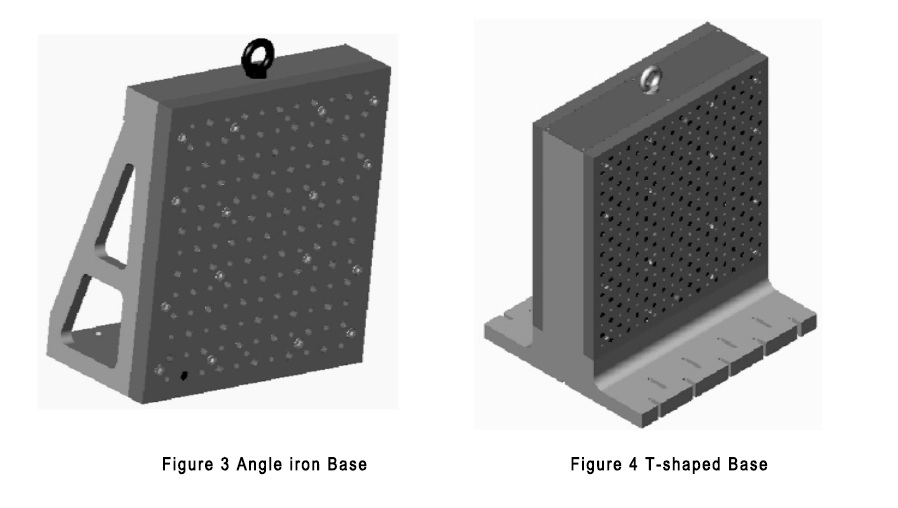

Flexible fixture unit is a new type of fixture element developed on the basis of the combination fixture, with board base (see Fig. 1), four-sided base (see Fig. 2), angle iron base (see Fig. 2), and a new type of fixture element developed on the basis of the combination fixture.

Each foundation is processed with accurate hole center distance position of a group of positioning holes and a group of fastening screw holes, which are distributed in a grid.

The use of the positioning holes in the base plate can be mounted on a variety of fixtures, through the fixture positioning mode, clamping mode, processing mode changes in combination, can ensure that the fixture a positioning fixture for multiple pieces of processing, or a positioning fixture for multi-face machining, shorten the CNC machine tool clamping downtime, give full play to its effectiveness.

When the processing object to change the species, only need to properly adjust the assembly mode or replace the corresponding fixture can be quickly converted to the processing of new parts, adaptability is very strong, you can better play the production of CNC machine tool flexibility.

Advantages of flexible fixture unit:

1) Flexible fixture unit has the advantages of clever structure, high precision, good rigidity, small volume, high strength of assembling and combining, high working load, fast and flexible assembling and adjusting installation, stable precision, safety and reliability.

2) Flexible fixture unit can be recycled through assembling-disassembling-reassembling.

Compared with the special fixture, it has obvious technical and economic effects, which can shorten the fixture manufacturing time and production preparation cycle, save metal materials and reduce costs.

3) Good generality and high degree of standardization.

The products are applicable to CNC machine tools of ISO, JIS, DIN and USA standards.

4) With sufficient strength and good toughness.

The components are made of high quality steel with surface hardening treatment, the surface hardness reaches HRC58~62. The shape and position tolerance of the main working surface of the product can reach IT3~4 level (IT4~6 level for traditional combination fixture), and the tolerance of the main parts can reach 0.01~0.005 mm (0.03~0.05 mm for traditional combination fixture).

2. Specialized fixtures and combination fixtures

Traditional special fixtures have four functions: positioning, clamping, guiding and tool setting, while CNC machine tools are generally equipped with contact test head, tool pre-setting instrument and tool setting parts and other equipment, which can be used by the machine tool to solve the problem of tool setting.

CNC machine tools by the program-controlled accurate positioning accuracy can be realized in the fixture tool guiding function.

Therefore, fixtures in CNC machining generally do not need guiding and tool setting functions, only require positioning and clamping functions, which can simplify the structure of the fixture.

Combined with flexible fixture units, specialized fixtures can be designed more easily. Fixture design only needs to consider how to quickly and reliably locate and clamp the workpiece, how to locate and clamp for multi-face machining or multi-piece machining, in order to shorten the fixture downtime of the CNC machine tool and give full play to its effectiveness.

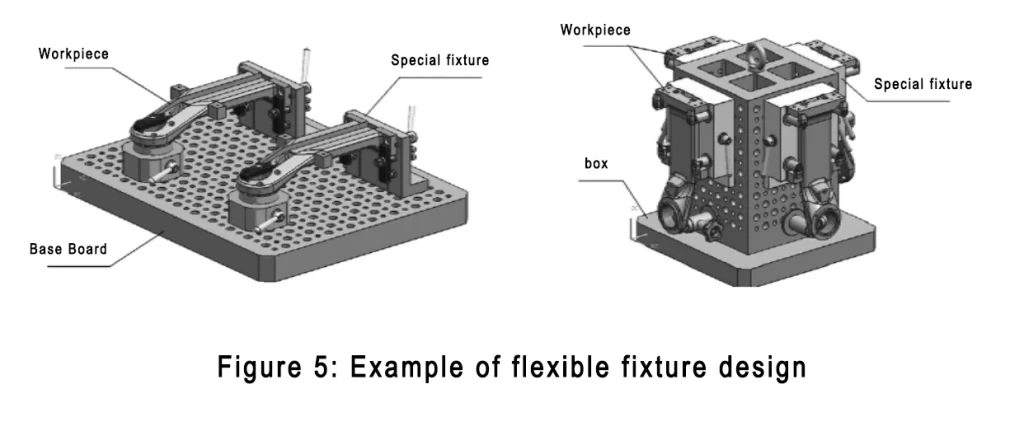

Flexible clamping unit and special fixtures combined with the application of the example shown in Figure 5. With the flexible fixture unit as the basis of the fixture, the positioning of the workpiece on the machine table becomes very convenient.

Specialized fixtures can be greatly simplified in structure and greatly reduced in weight. Therefore, the speed of fixture design and machining can be increased, and the cost of fixtures can be reduced.

When the product batch is very small or special fixtures need to be changed due to damage, the flexible fixture unit can also be combined with a combination of fixtures, temporary fixtures or transition fixtures to ensure that the product production is carried out smoothly.

3. Flexible fixture design and assembly

Flexible fixture system assembly is simple, unlike the combination of fixtures that need to be assembled by specially trained assemblers to assemble fixtures.

The flexible fixture unit can be selected by the fixture designer during the design of the fixture, and its assembly relationship and requirements are reflected on the fixture drawings, and the assembly and inspection are completed by the fixture production department, which can not only ensure the accuracy and quality of the fixture, but also prepare the fixture in advance according to the production of the product.

Flexible fixture with corresponding two-dimensional drawings and three-dimensional graphics of the workpiece, in the current process card or the upcoming trend of three-dimensional process can be directly referenced, so it is conducive to the guidance of product production and process management of the workpiece, but also to improve the coefficient of process equipment.

An example of a flexible fixture design is shown in Fig. 5.

4. Establishment of Flexible Fixture System

The establishment of flexible fixture system requires the following aspects.

1) Equip a certain number of flexible fixture units.

In order to set up a flexible fixture system, it is necessary to equip a considerable number of flexible fixture units to realize the normal operation of the system.

2) Formulate the design, manufacturing and management of flexible fixture system specifications.

Only the development of strict design, manufacturing and management specifications to ensure the normal operation of the flexible fixture system.

The specification includes the tooling designer to design the fixture how to refer to the flexible fixture unit, fixture manufacturing and assembly by what departments, how to store and maintain the fixture, how to loan the use of the use of disassembly and cleaning after the use of the return and other issues.

3)Technical training

Before the application of flexible fixture system, it is necessary to provide technical training to the relevant personnel to carry out flexible fixture system design, manufacturing and management specifications of the publicity.

Conclusion

CNC machine tool fixtures in a variety of forms, each enterprise according to the characteristics of their products and production needs to use the corresponding fixture system.

Flexible fixture system with high precision, high rigidity, modularity, generalization and rapid response and other advantages, especially suitable for product batch size, varieties, high precision, fast update of the enterprise’s CNC machining needs, is the future of CNC machine tool fixtures is a major direction of development, it is worthwhile to promote the application.