What are the factors affecting the machining accuracy of CNC machine tools? how to improve?

CNC machine tools are indispensable core equipment in the modern manufacturing industry. Their machining accuracy directly determines the quality and performance of the product.

With the continuous progress of industrial technology and the rapid development of the manufacturing industry, the requirements for the machining accuracy of CNC machine tools have become increasingly high.

Therefore, it is of great significance to in-depth study the various factors affecting the machining accuracy of CNC machine tools and actively explore and practice effective ways to improve this accuracy to enhance the overall level of manufacturing and competitiveness.

CNC machine tool machining accuracy factors

Error factors

A CNC machine tool may make various errors during processing due to the tool angle, measurement scale, and other reasons, which in turn reduces the machine tool’s precision.

The use of CNC machine tools for processing should be based on their specific accuracy requirements to control the level count.

For example, part of the machine tool for processing accuracy requirements is relatively low, the level meter count can be controlled below 0.04mm/1000mm, while for some of the higher precision requirements of the machine tool, the level count should be controlled to 0.02mm/1000mm.

Therefore, the selection of the correct tool size and angle is to ensure that the machine tool machining accuracy, to ensure that the machining task is completed accurately the key link.

If the tool size and angle are not selected accurately, it will affect the accuracy of parts processing and lead to serious errors.

In addition, practice shows that the thermal deformation of CNC machine tool machining process, is also an important cause of machine tool machining error, the error may even reach 40% ~ 70%.

With the continuous development of CNC machine tool technology, more and more CNC systems began to use the motor sliding ball for tool adjustment to ensure the accuracy of CNC machining.

The ball, in the case of long-term continuous rotation, will lead to an increase in the bearing gap, which in turn makes the CNC machine parts play an external role, gradually producing deviation in the forward and reverse roles.

In addition, due to the different angles of mechanical force, its rotation process will also affect the accuracy and overall performance because of the difference in force, which in turn affects the accuracy and quality of parts processing.

Servo factors

In the actual operation process, CNC machine tool processing accuracy may also be affected by various other factors, such as the servo control system.

The servo control system can effectively control the operation of the CNC machine tool in the entire CNC machine tool system, ensuring stable operation, reducing error in the operation process, and improving the precision and quality of machine tool processing.

As the main source of power for the operation of CNC machine tool systems, the performance of the servo control system directly affects the machine tool’s machining accuracy.

The precision, response speed and stability of the servo system are the key factors affecting the machining accuracy of CNC machine tools.

If the servo system’s precision is not high enough, it will not be able to ensure the machine tool’s precise positioning and movement trajectory, thus affecting the machining accuracy.

Slow response speed causes the machine tool to lag in the machining process, affecting machining efficiency and accuracy.

Poor stability will lead to irregular fluctuations in the machining process, affecting the machining quality.

Therefore, in the use of CNC machine tools for parts processing, to realize the precise control of the servo system, the operator needs to use the servo system to effectively control the ball screw, so as not to affect the parts processing accuracy due to unnecessary errors.

Solutions

Error compensation

Various deviations will inevitably occur in CNC machine tool processing. Error compensation technology can be used to solve these deviations and ensure the accuracy of CNC machine tool processing.

CNC machine tool operators in the processing process, should be based on the actual situation of the CNC machine tool system and the demand for parts processing, the CNC system is set up for compensation, to minimize the reduction of processing accuracy due to error factors.

Error compensation technology includes software compensation and hardware compensation in two ways.

Software compensation is mainly achieved through the compensation algorithm inside the CNC system, the application of programming technology, the precise positioning of the parameter unit, and the real-time calculation and correction of the machine tool’s motion error, which combine to control the backlash and realize reasonable compensation.

For example, by establishing an error model, the thermal deformation of the machine tool, tool wear and other errors can be compensated. On the other hand, hardware compensation mainly refers to the reasonable adjustment of machine tool hardware to reduce the error.

For example, by adjusting the preload force of the ball screw, the error caused by mechanical clearance can be effectively reduced.

In addition, CNC machine tool operators can install high-precision sensors and feedback systems to monitor the machine tool’s running status in real time, finding and adjusting deviations in a timely manner, thereby improving machining accuracy.

Servo compensation

In the CNC machine tool system, the servo control system plays a crucial role and plays a key role.

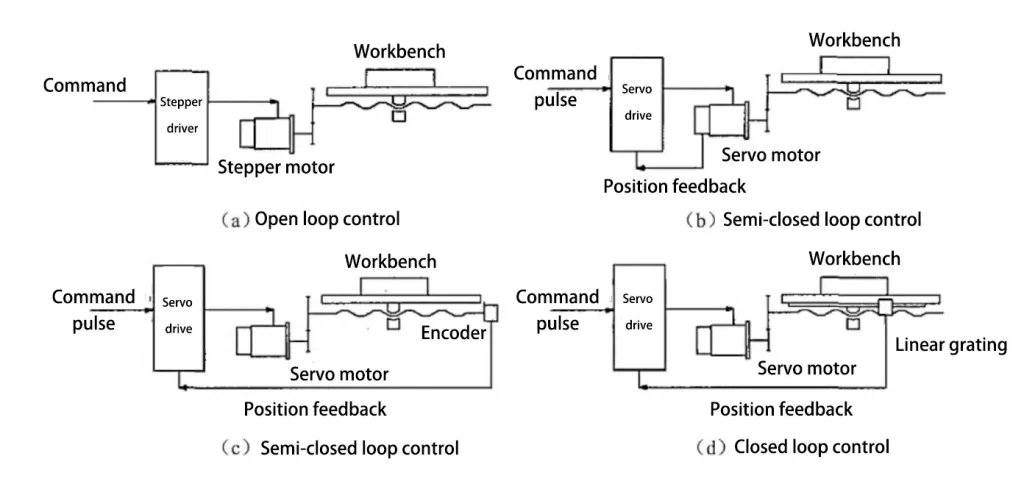

According to the different control system structures, CNC machine tool servo control systems can be divided into four types, as shown in Figure 1, and directly determine the efficiency and quality of parts processing.

Similarly, once the servo control system failure, will not only affect the efficiency of CNC machine tool processing, and will even seriously affect the accuracy of CNC machine tool processing.

Regular maintenance and calibration of the servo system are necessary to ensure its stability and accuracy.

CNC machine tool maintenance personnel should check whether the connection between the servo motor and the drive is firm to ensure no loose or damaged parts. They should also regularly check the servo system’s parameter settings to ensure that they match the machine tool’s operational requirements.

In addition, maintenance personnel can adjust the control parameters to ensure the response speed and stability of the servo system, such as changing the PID parameters to achieve the best control results.

In some cases, replacing or upgrading the servo system’s hardware components may be necessary to improve its performance. For example, using higher-precision encoders can improve position detection accuracy, thereby enhancing machining accuracy.

Finally, a complete maintenance program should be established for servo system maintenance, including regular inspection, cleaning, and lubrication to ensure the long-term stable operation of the servo system.

CNC machine tool machining accuracy protection measures

Strengthen the awareness of personnel, enhance the quality of the team

In the processing of CNC machine tools, to ensure that the machining accuracy meets the expected standards, enterprises should actively take a series of measures to strengthen the management and training of CNC machine tool operators and maintenance personnel. This will enable them to continuously improve their professional skills and operating level and thus ensure the machine tool’s efficient and accurate operation.

On the one hand, the enterprise can organize systematic training courses regularly so that operators and maintenance personnel can master the latest CNC machine technology, machining process, and error compensation methods.

This will help them understand the machine tool’s performance and improve the accuracy and efficiency of the operation.

On the other hand, the enterprise should encourage technical exchanges between employees and experience sharing, so that employees through the analysis of actual cases, to master the ability to solve practical problems in the process of CNC machine tool processing, thus promoting the dissemination of professional knowledge at the same time, but also able to stimulate the staff’s innovative thinking, so that they are better able to control the machining errors in their daily work to ensure that the stability of the machining accuracy of CNC machine tools.

To further stimulate employees’ enthusiasm, enterprises should establish a perfect incentive mechanism to encourage employees to actively participate in improving CNC machine machining technology and innovation activities. This would prompt employees to pay more attention to controlling machining accuracy under the drive to provide rewards and recognition.

The incentive mechanism can include bonuses, promotion opportunities, recognition, and other forms to meet the needs of different employees better and motivate them to continue making progress.

Improve the processing technology, optimize the processing procedures

In the processing of CNC machine tools, to further improve the machining accuracy, to strengthen the awareness of personnel and enhance the quality of the team based on improving the machining process and optimizing the processing procedures are equally important.

Continuous improvement of CNC machine tool processing technology can effectively reduce errors in the processing process and improve the processing quality of parts.

On the one hand, enterprises should constantly update and optimize the machining process, scientific planning tool selection, cutting parameter settings, and coolant use.

For example, enterprises should be based on the demand for CNC machine tool processing, selection of suitable for specific materials and processing requirements of the tool, thereby minimizing tool wear and prolonging the service life of the tool, while improving the finish of the machined surface;

Reasonable setting of cutting speed, feed rate, depth of cut, and other parameters can effectively avoid machine tool overload and tool breakage, ensuring the stability of the machining process and the machining accuracy of the parts.

On the other hand, optimize the processing procedure. According to the CNC machine tool technician, writing and adjusting the CNC program can realize the precise control of the machine tool movement.

When writing the program, technicians should fully consider the dynamic characteristics of the machine tool, avoiding operations such as emergency stops, rapid rotation and other operations that may lead to machine vibration and machining errors, and make full use of the advanced programming functions provided by modern CNC systems, such as subroutines, macros, and loops, etc., to simplify the program structure, improve the efficiency of programming, and reduce human error, thus improving the machining accuracy.

In addition, enterprises should also pay attention to real-time monitoring and feedback during the processing of CNC machine tools, and through the installation of high-precision sensors and feedback systems, real-time monitoring of the operating status of the machine tool and the quality of machining, timely detection and adjustment of deviations, to effectively avoid machining errors due to abnormalities in the state of the machine tool.

At the same time, it should also focus on the Internet of Things, big data analysis, and other modern information technology in the processing of CNC machine tools to realize an in-depth analysis of the machining process, find potential problems, and take measures in advance to ensure the stability of the machining accuracy.

Determine the cutting amount, improve the cutting environment

In the CNC machine tool machining process, a reasonable choice of cutting amount will directly affect the machining accuracy. A reasonable cutting amount can effectively reduce the thermal deformation of the CNC machine tool machining process and tool wear, thereby improving machining accuracy.

Enterprises should be based on the machine tool’s performance and the nature of the material, the cutting speed, feed rate, depth of cut, and other parameters for scientific selection. For example, reducing the cutting speed should be appropriate for some of the harder materials to reduce tool wear and extend tool life.

At the same time, the feed rate and depth of cut should also be reasonably controlled to effectively avoid tool exercise or machine tool overload, which affects the stability of the CNC machine tool machining process and machining accuracy.

In addition to a reasonable choice of cutting dosage, improving the cutting environment is also an important measure to improve the accuracy of CNC machine tool machining.

A good cutting environment can effectively reduce thermal deformation and vibration during CNC machine tool machining, thereby improving machining accuracy.

The reasonable use of cutting fluid should be ensured to achieve this effect.

Cutting fluid can reduce the cutting temperature, reduce the friction between the tool and the workpiece, and improve the finish of the machined surface.

Meanwhile, improving the machine tool’s cooling system to ensure uniform distribution and effective cooling of the cutting fluid can further improve machining accuracy.

Regularly check and maintain the machine tool’s guideway and sliding parts to ensure that they are well lubricated and reduce thermal deformation and wear caused by friction.

On this basis, to further improve the machining accuracy of CNC machine tools, enterprises should also pay attention to improving the performance of the machine tool itself and carry out regular inspection and maintenance to ensure that the machine tool’s mechanical structure and electrical system are in the best condition.

For example, regular cleaning and lubrication of guide rails, screws and other key components can effectively reduce wear and improve the precision of movement; regular inspection of the electrical system of the machine tool to ensure that all the cables are firmly connected, there is no aging or damage, to avoid machining errors due to electrical failure effectively.

Reasonable selection of tools, improve machining accuracy

In CNC machine tool processing, tool selection also has an essential impact on machining accuracy. Choosing the right tool can significantly improve the processing efficiency and processing quality, reduce tool wear, extend tool life, thereby enhancing the overall machining accuracy.

On the one hand, enterprises should base their decisions on the type of processing material, hardness, toughness, and processing requirements, as well as choosing the appropriate tool material and geometric parameters.

For example, carbide or ceramic tools should be selected for processing materials with high hardness to improve their wear resistance and cutting performance. The geometric parameters such as the front angle, back angle, and helix angle of the tool should be reasonably optimized according to the machining conditions to reduce the cutting force and cutting heat and improve the finish of the machined surface.

On the other hand, enterprises should regularly inspect and maintain the tools to ensure they are in the best condition. Worn tools should be replaced in time to avoid machining errors caused by tool wear.

In addition, an advanced tool management system can effectively track tool use and predict tool life, rationally arranging tool replacement and maintenance.

In addition, focus on tool innovation and improvement. With the development of materials science and manufacturing technology, new tool materials and coating technology continue to emerge, and their application in CNC technology processing can effectively improve the tool’s performance and machining accuracy.

Enterprises should focus on introducing new tool materials and coating technology to maintain their competitive advantage in machining accuracy.

Scientific selection of machine tools, the use of suitable equipment

Enterprises should select CNC machine tools based on the specific needs of the processing task and scientifically choose suitable equipment. Different types of CNC machine tools have their own characteristics in processing accuracy, range, and efficiency. Therefore, a reasonable choice of machine tools to ensure processing accuracy is critical.

Enterprises should assess the complexity and precision requirements of CNC machine tool processing tasks for scientific assessment, and based on the assessment results, select CNC machine tools with the corresponding accuracy level and function.

For example, to ensure processing quality, high-precision CNC machine tools should be chosen for high-precision requirements in parts processing.

When selecting CNC machine tools, enterprises should also fully consider their processing range and flexibility. A machine tool with a wide range of processing capabilities can adapt to more processing tasks and improve equipment utilization.

With the development of technology, some new CNC machine tools are equipped with high-speed machining, multi-axis linkage, and other advanced features, which can further improve processing efficiency and precision.

Therefore, enterprises should pay attention to industry technological developments and introduce new CNC machine tools at the right time to maintain the advancement of processing technology. Enterprises should also pay attention to machine tool installation and commissioning.

Ensure that the machine tool is installed in a suitable environment. Accurate commissioning can maximize the machine tool’s performance and ensure the stability of machining accuracy.

In short, the scientific selection of machine tool equipment and reasonable configuration can significantly improve the machining accuracy of CNC machine tools to meet the growing demand for processing.

Conclusion

In short, CNC machine tool machining accuracy is a systematic project that requires comprehensive consideration and implementation from various perspectives.

Enterprises need to fully understand the factors affecting the adoption of reasonable and practical solutions, strengthen personnel training, improve the machining process, determine the cutting dosage, rationally select tools, scientifically select machine tools, and find other ways to enhance CNC machine tool machining accuracy.

In the fierce market competition, only the constant pursuit of excellence can win the trust and satisfaction of customers and maintain a leading position in CNC machine tool processing.