What Is Screen Printing, and How Does It Work on Different Materials?

The process of creating a printed design by pressing ink through a stenciled mesh screen is known as “screen printing.” This technique is widely used across various industries, and it’s possible that you’ve used or worn a screen-printed product without realizing it. It’s also called serigraphy or silk screen printing, these terms all describe the same basic method.

What is it?

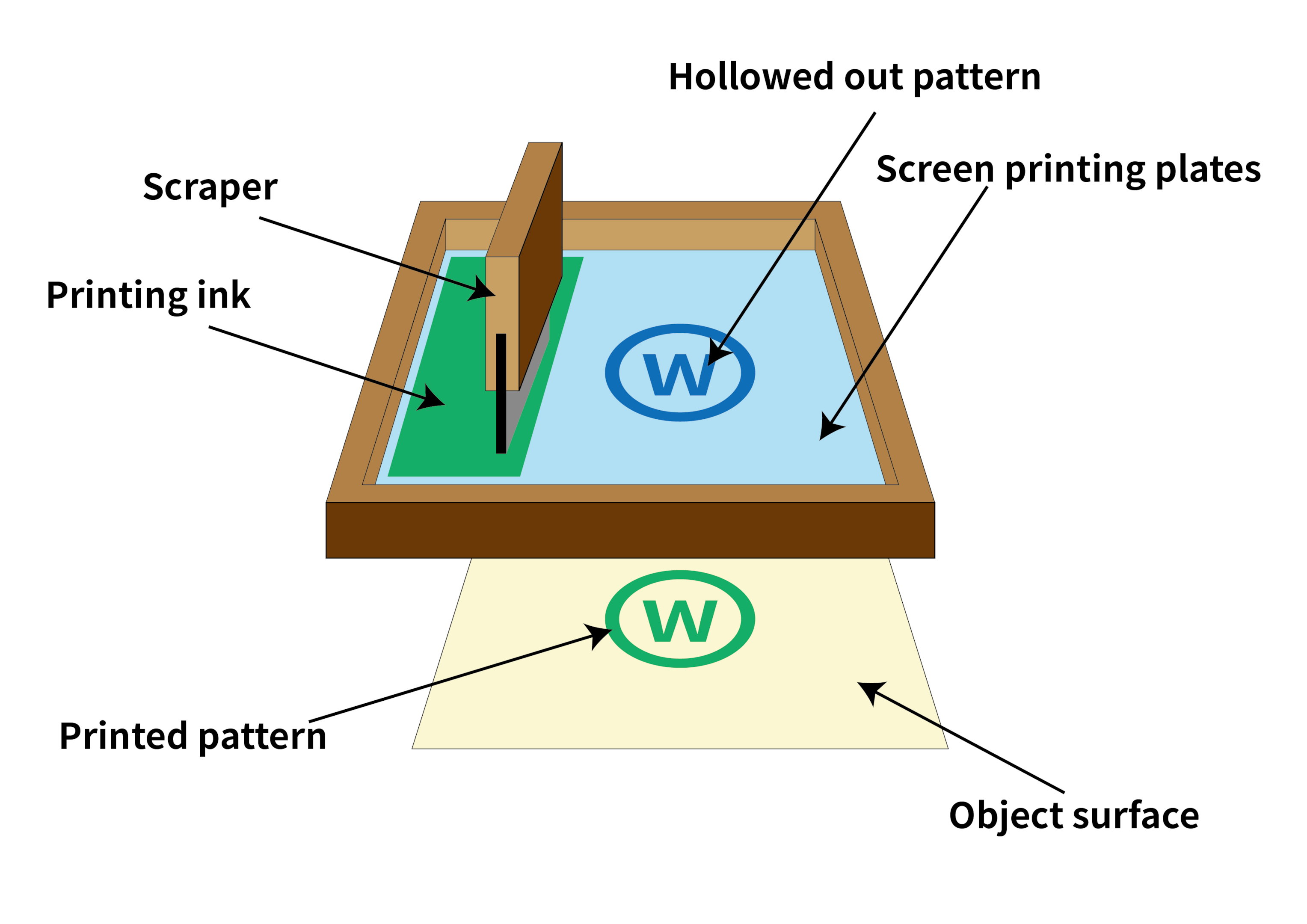

Screenprinting involves the application of ink through a mesh screen onto a surface. By selectively blocking certain areas of the screen with a stencil, the printing ink is prevented from passing through those areas. The ink that does pass through the unblocked areas creates the printed image. It can be used on almost any type of substrate, including those with uneven or round surfaces.

History

It has a rich history that dates back to ancient times. Originating in China around AD 950, the technique was initially used to print patterns onto fabric. In Japan, artisans adapted the method to transfer designs onto paper and fabric by using a stiff brush to push ink through a mesh screen woven from human hair.

It was introduced to Europe in the 18th century, but its use as a fabric printing method was limited due to the high cost of silk mesh at the time. However, with the advent of the Silk Road, imported silk became more affordable, and screen printing gradually gained popularity as a profitable way to print fabric.

In the early 20th century, photo-sensitized emulsions were developed, making it easier for artisans to create complex stencil designs. Artists also began experimenting with screen printing as an artistic medium in the 1930s, calling it “serigraphy” to distinguish it from industrial printing. By the 1960s, artists like Eduardo Paolozzi and Andy Warhol were using the printing to create fine art. Warhol’s famous Marilyn Diptych is a prime example of screen printing as an art form and is considered a hallmark of the pop-art movement.

Today, screen printing is used both as an artistic medium and as an industrial printing process. With the ability to reproduce the same design hundreds or even thousands of times using a single stencil, this printing is an excellent technique for producing large orders of custom clothing.

Process Step

Here are the steps involved in the printing process:

Design Creation

The first step is to create the design or artwork that will be printed. This can be done using a variety of methods such as hand drawing, computer graphics software, or taking a photograph.

Screen Preparation

A mesh screen is stretched over a frame and coated with a photosensitive emulsion. The emulsion is then exposed to light with the design transparency, hardening the emulsion in the areas not covered by the design, and creating a stencil.

Ink Preparation

The ink used for the printing is typically a thick, paste-like substance that needs to be mixed and thinned to the desired consistency for printing. Different colors may be mixed together to create custom colors.

Printing

The screen with the stencil is positioned on top of the item to be printed. Ink is then applied to the top of the screen and spread evenly over the stencil with a squeegee. The ink is forced through the open areas of the stencil onto the item, creating the printed image.

Drying and Curing

Once the image has been printed, it needs to be dried and cured to set the ink onto the surface. This can be done through air-drying or by using a heat press, depending on the ink type and substrate.

Cleaning

The screen and squeegee need to be thoroughly cleaned after each use to remove any remaining ink and emulsion, which may clog the mesh or affect the quality of future prints.

Types of Screen Printing

There are numerous screen printing processes available today, and each one offers unique benefits and requires additional steps to achieve its desired effects. Here are some of the most prevalent types:

Grayscale Printing

This technique involves incorporating various shades of gray alongside black and white. To achieve these shades, screen printers adjust the levels of black or white light. As a result, this is a highly cost-effective screen printing method as there’s no need to invest in different-colored dyes. Additionally, it yields high-quality black-and-white images.

Spot Color Screen Printing

Spot color is a frequently employed screen printing technique, particularly suitable for printing on T-shirts, jackets, and hoodies. It’s relatively uncomplicated compared to other screen printing methods. This approach involves using the stock color of the ink, which is applied over the stencil of the screen mesh.

Discharge Screen Printing

Discharge screen printing uses a special type of ink that removes the dye from a substrate, leaving a lighter color behind. This technique is commonly used on dark-colored fabrics to create a faded or vintage effect.

Halftone Printing

The technique of halftoning involves creating shading by utilizing small dots. This is commonly utilized for printing images using a single color, while still achieving a visually appealing effect through gradients. In this process, only one color is used, which is then converted into halftones, resulting in various shades when viewed from a distance.

Water-based

Water-based screen printing uses inks that are thinner than standard screen printing inks and are composed primarily of water. This makes them more eco-friendly, but they may not be as durable or vibrant as standard inks.

Materials Used For Screen Printing

Screen printing is a traditional method that is commonly used for printing on fabric and paper materials. It is widely used in the textile industry to print designs on t-shirts and other fabrics such as silk, cotton, polyester, and organza. Screen printing can be used on any type of fabric that requires printing. Different types of inks are used for different materials, including ceramics, wood, glass, metal, and plastic.

In addition to fabric, the printing is also used in marketing and advertising for printing posters, flyers, and other promotional items that require graphics. Screen printing is preferred over digital printing for limited edition printing, as digital printing is more expensive for small-scale production.

Screen printing is also used for printing on plastic substrates.

Polyvinyl chloride (PVC) is a commonly used plastic for the printing due to its bright color, resistance to breakage and acid/alkali, and low cost. However, some materials added during PVC production may be toxic, making PVC products unsuitable for food containers.

ABS resin plastic is another engineering plastic that is widely used in televisions, calculators, and other products due to its easy processing and forming.

Polyethylene and polypropylene are other commonly used plastics for screen printing, as they can be processed into various finished products through extrusion, injection molding, and other molding processes.

How Screen Printing Plastic And Other Materials Works

Various screen printing methods exist, all utilizing identical fundamental techniques. A mesh is utilized, typically consisting of synthetic polymers like nylon, with a smaller aperture utilized for designs necessitating more intricate detail. The mesh must be mounted onto a frame under tension for it to work. The frame, which can be made of materials such as wood or aluminum, is dependent on the complexity of the machine or artisanal procedure. The mesh tension can be tested using a tensiometer.

To create a stencil of the desired design’s negative image, certain parts of the screen are blocked off, with the ink appearing on the substrate in the open areas. Prior to printing, the frame and screen must undergo the pre-press process, in which an emulsion is applied across the mesh.

Once the emulsion has dried, it is selectively exposed to ultraviolet light through a film printed with the required design. The exposure hardens the emulsion in the exposed areas but softens the unexposed parts, which are then washed away using a water spray, leaving behind a clean space in the mesh in the same shape as the desired image. This clean space allows the passage of ink, and the process is positive.

The surface supporting the fabric is referred to as a pallet in fabric printing. It is coated with wide pallet tape to safeguard it from any ink leaks, preventing potential staining or transfer of ink onto the next substrate.

Screen Printing Applications

Glass&Ceramic

In the present day, the printing still holds an important position in the manufacturing of glass and ceramic items, serving the needs of both the industrial and consumer sectors. The uniqueness of screen printing lies in its ability to overcome various obstacles encountered by glass decorators during the production process.

Electronics Printing

At present, the Printed Electronics sector is experiencing remarkable expansion, fueled by the rising demand for technological devices. Screen printing remains a cost-effective, efficient, and dependable production choice, owing to advancements in printing technologies, equipment, and materials.

Textile Printing

Chromaline is aware that contemporary textile printers require stencil systems that offer more than just ink resistance and on-press durability; screen making and screen turnaround times are equally critical. Textile printers seek emulsion solutions that not only reduce costs and boost efficiency but also aid in delivering a larger quantity of high-quality products.

Graphics Printing

Modern graphic printers have the potential to screen print virtually any design or text onto a wide range of substrates and 3-dimensional objects, creating seemingly limitless possibilities. However, this comes with its own set of challenges. Selecting the right emulsion and ensuring its optimal performance is a crucial factor in achieving success for every graphic application.

Conclusion

In conclusion, CapableMachining said this printing remains a highly versatile and widely used printing technique in various industries, including textiles, electronics, advertising, and packaging. With advancements in printing technologies, equipment, and materials, screen printing has become more efficient, cost-effective, and capable of producing high-quality outputs.

While challenges such as emulsion selection and screen-making turnaround times persist, screen printing continues to offer numerous benefits such as the ability to print on almost any surface, reproduce intricate designs, and achieve vibrant colors. As such, it is expected to remain a popular printing method for years to come.