You Must Know the Difference Between a Fillet and Chamfer

Fillets and chamfers are two distinct approaches to shaping the meeting edges of two surfaces on a part. Their purpose is to alleviate the presence of sharp edges and corners. A chamfer achieves this by replacing the abrupt change in direction with an angled slope, whereas a fillet creates a smooth curve that connects the two surfaces seamlessly. The implementation of fillets helps to mitigate stress concentration at corners or areas where sections change by spreading applied stresses across larger surface areas.

Although fillets are more challenging to manufacture compared to chamfers, they effectively minimize stress concentration throughout the interior or exterior corner region, resulting in more robust components. Conversely, chamfers offer the advantage of simplified manufacturing and assembly for mating parts. This article aims to elucidate the distinctions between fillets and chamfers, as well as their respective applications.

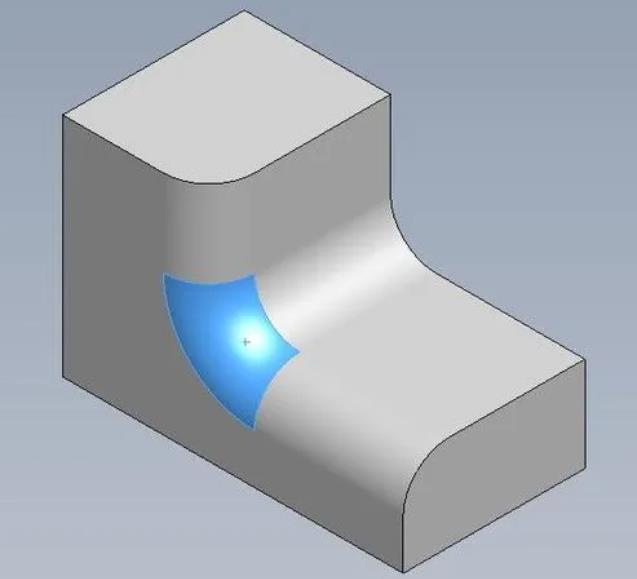

What is a Fillet?

A fillet is a rounded corner or curved feature that is created at the intersection of two surfaces or the transition between a surface and an edge. In the context of design and manufacturing, a fillet is typically used to smooth out sharp corners and edges, creating a smooth and gradual transition between surfaces.

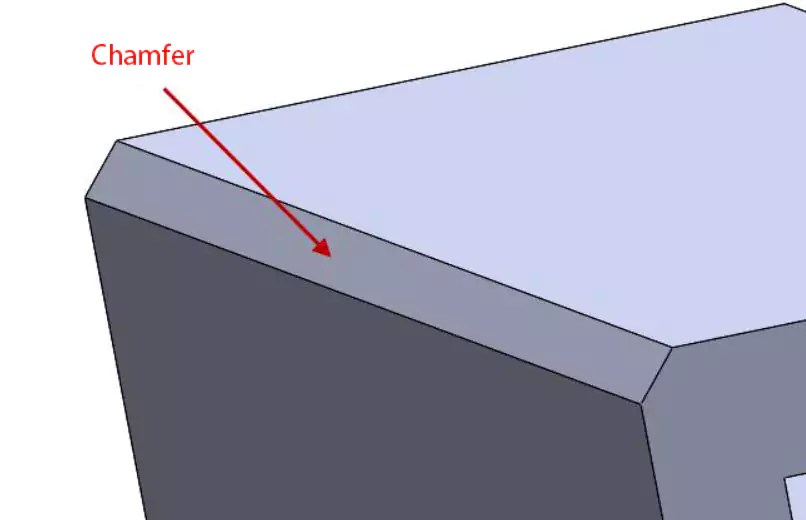

What is a Chamfer?

A chamfer refers to the angled or sloped edges and corners found in a part’s design, serving as the opposite of a fillet. Unlike a fillet, which features a curved shape, a chamfer consists of a straight edge with a sharp angle. Machinists employ chamfers in parts that necessitate edges with high-stress concentration. By directing stress to a specific area of the design, chamfers can be advantageous. However, if a chamfer angle is used in designs that require low-stress concentration, the material can easily deform.

Differences between Fillet and Chamfer

There are some differences between Fillet and Chamfer that you should know.

Functions

The purpose of both fillets and chamfers is to improve the design, functionality, and manufacturing of parts, but they serve different needs and offer unique advantages based on the specific requirements of the application.

Fillet

1. Smooth out sharp edges and corners: Fillets are used to eliminate sharp angles and create a smooth transition between surfaces, resulting in a visually appealing design.

2. Create a gradual transition between surfaces: Fillets help in achieving a seamless blend between two surfaces, enhancing the aesthetics and overall quality of the part or product.

3. Enhance aesthetics: Fillets can add a sense of elegance and refinement to the sharp edge of a design by softening hard edges and giving a more pleasing appearance.

4. Reduce stress concentration: By distributing applied stresses across a larger surface area, fillets help alleviate stress concentration at corners or section changes. This can improve the strength and durability of the part, reducing the likelihood of failure.

Chamfer

1. Remove sharp corners: Chamfers are used to eliminate sharp corners by creating an angled slope at the interior corner of the edge. This can prevent injury from sharp edges and make the part safer to handle.

2. Create a sloped or angled corner at the edge: Chamfers provide a flat or angled surface at the edge, which can have functional benefits such as easy removal or insertion of parts, better sealing, or improved alignment.

3. Facilitate assembly of mating parts: Chamfers on the edges of parts can make the assembly process smoother by allowing easier alignment and engagement between mating components.

4. Simplify manufacturing processes: Chamfers are often simpler to manufacture compared to fillets, requiring less complex machining or forming operations. This can save time and cost during production.

Design and Appearance

The design and appearance of fillets and chamfers differ in terms of their shape and visual impact. Fillets introduce a more rounded edge or curved feature, creating a smooth and continuous curve between surfaces. They offer a seamless transition, resulting in a softer and more flowing appearance. In contrast, chamfers provide a flat or angled surface, creating a distinct break or slope at the edge or corner. This angular profile adds visual contrast and definition to the design.

Fillet

1. Rounded or curved feature: Fillets create a smooth and rounded transition between surfaces, eliminating sharp angles and corners.

2. Creates a seamless and continuous curve: Fillets blend the two surfaces together without any sudden changes, resulting in a visually pleasing and aesthetically appealing design.

3. Can vary in size and radius: Fillets can be designed with different sizes and radii, allowing flexibility in achieving the desired curvature and visual effect.

Chamfer

1. Flat or angled feature: Chamfers create a flat or angled surface at the edge or corner, forming a beveled edge or profile.

2. Creates a distinct break or slope: chamfered edges Unlike fillets, chamfers introduce a clear break or slope between two surfaces, adding visual contrast and definition.

3. Can vary in angle and distance: Chamfers can be designed with different angles and distances, allowing for customization based on design requirements and aesthetic preferences.

The size and radius of fillets can be adjusted to achieve the desired curvature and blend between surfaces. On the other hand, chamfers can be customized in terms of the angle and distance to suit specific design requirements. Both fillets and chamfers provide design options for different aesthetic preferences and functional needs, allowing designers to enhance the visual appeal and overall quality of the part or product.

Stress Concentration

Stress concentration refers to the accumulation of stress in localized areas of a part or component. Fillets are advantageous in reducing stress concentration by distributing applied stresses across a larger surface area. This helps to minimize the risk of failure and improve the overall strength of the design.

On the other hand, chamfers, with their sharp angles and smaller contact areas, may result in higher stress concentrations, especially in parts subjected to significant loads or fatigue. In applications where low-stress concentration is necessary, the use of chamfers can lead to material deformation or failure. Therefore, the choice between fillets and chamfers should consider the specific stress requirements and potential failure modes of the design.

Fillet

1. Distributes stress across a larger surface area: Fillets are effective in spreading applied stresses over a larger region, reducing stress concentration at corners or sections where abrupt changes occur.

2. Reduces the likelihood of failure: By distributing stress more evenly, fillets help to mitigate stress concentrations, enhancing the overall strength and durability of the part or component.

Chamfer

1. Does not distribute stress as effectively as a fillet: Chamfers do not offer the same level of stress distribution as fillets due to their sharp angle and smaller contact area.

2. May result in higher stress concentration: The sharp angle of a chamfer can create localized stress concentrations, particularly in parts subjected to high loads or fatigue.

3. Potential for material deformation: In designs where low-stress concentration is required, the use of chamfers can lead to material deformation or failure under stress.

When Choosing Between a Fillet and Chamfer

When faced with the decision between using a fillet or chamfer in their design, machinists frequently encounter a sense of uncertainty. To prevent becoming mired in confusion, it is advisable to take into account the following factors.

Cost

The choice between a fillet and chamfer can impact the overall cost of a project. Fillets typically require more material to be removed, which can increase manufacturing costs. On the other hand, chamfers involve cutting or grinding at an angle, which may require additional tooling or setup costs. Considering the specific requirements of the project and evaluating the associated costs can help make an informed decision.

Rust Resistance

Another crucial factor to consider is the susceptibility to rust. Fillets, with their curved transitions, can potentially accumulate moisture or contaminants, making them more prone to rust formation over time. Chamfers, with their angled or rounded edges, are less likely to trap moisture or debris and may offer better rust resistance. If corrosion resistance is a priority for the application, choosing a chamfer might be advantageous.

Machining Time

The time required to machine a part can also be a decisive factor. Fillets typically involve more complex machining operations, such as blending or contouring, which can increase the overall machining time. In contrast, chamfers are relatively simpler to machine, often requiring only a straight cut or grind. If time efficiency is crucial, opting for chamfers could help expedite the manufacturing process.

It’s important to note that these factors are not exhaustive, and other considerations such as aesthetics, structural requirements, and functionality of the design should also be taken into account. Consulting with experienced machinists or design professionals can provide valuable insights to help make the best decision for a specific project.

Conclusion

The article provided a comprehensive comparison between fillet and chamfer, defining their characteristics and highlighting their distinct uses. For further information on fillet and chamfer, it is recommended to get in touch with a representative from CapableMachining.

We offer an extensive array of manufacturing capabilities and valuable services to cater to your prototyping and production requirements. To explore more about their offerings or to request a complimentary quote without any obligations, please visit our website.