Application of on-machine measurement technology in CNC machining

Why is on-machine measuring technology necessary in CNC machining?

1. Improvement of manufacturing quality in machining

In the past, the production process of machining was often susceptible to a variety of factors, including the role of man is particularly obvious, often due to human error or improper operation caused by the loss of quality problems. At the same time, the use of CNC machining technology can be better avoided by a certain impact and is conducive to ensuring the production quality of machine tools. The application of CNC machining technology can significantly improve the level of automation of machining manufacturing because the process does not require human operation, so it can avoid human error caused by the quality of the operation. In addition, the use of CNC machining technology to enhance the precision of machine tools, and to improve the quality of machine tools has an important role.

2. Enhance the efficiency of machine tool processing

Usually, machining through a series of processes to achieve high quality and high standards of product requirements, because the process is more complex and takes longer, so the conventional process to complete a lot of time will be wasted, and the processing efficiency in this case is not high. In the whole process, the machine tool plays a key role, only to effectively improve the efficiency of the process, and strengthen the control of the machine tool, to fundamentally improve the efficiency of the process. The use of CNC technology can help machine tools and equipment to complete machining at high speed, precision, and one-time completion of rough milling, fine milling, polishing, and other related processes, and the processing process does not produce much heat, which does not only improves productivity but also reduces production costs.

3. Enhancement of machining precision

Compared with traditional machining technology, the use of CNC technology can to a certain extent improve the accuracy of processing, such as the use of electrochemical reaction, to remove a large number of metals on the mold, while avoiding the traditional technology caused by temperature changes in the flying edge, cracks, residual stress, and other issues. The use of CNC technology is not affected by human factors and precise control of time, so the entire system will be in accordance with the set procedures for the process of processing, through this precise system of machining made of mold surface roughness will be greatly reduced, and thus smoother. Therefore, the use of CNC technology in machine tools will greatly improve the accuracy and quality of machine tools.

4. Reduced tool wear

Cutting cemented carbide by the traditional method will cause great damage to the tools during the cutting process because of the high hardness tools used. While in the use of CNC machining technology, the machining will not cause more serious problems and can reduce the wear and tear of the tool to prevent damage to the tool.

In conclusion, the application of machine measurement technology in CNC machining can improve production efficiency, reduce costs, improve product accuracy, and make the whole machining process more stable and controllable.

Characteristics of the application of on-machine measuring technology

From the point of view of the measurement of the workpiece, it is necessary to measure its length at the beginning of the running phase of production and to test the width after the completion of production. When the tool is placed on the machine tool, the fixture clamps are moved tightly and the positioning of the tool is tested using a probe, this operation can compensate for the deviations that occur in the actual positioning of the tool in the jigs and fixtures, thus enhancing the accuracy of the mass-produced products.

In addition, probes can also be utilized in this process to monitor the positioning of completed process parameters. After machining is completed, the machined parts of the side head are effectively measured to ensure that the dimensions follow the requirements, and once unqualified products are detected, the machine tool will automatically alert and communicate the message to the relevant staff. In addition, the use of on-machine inspection technology can improve the accuracy of the products to a certain extent, and ensure the stability of the products in the production process, to effectively control their quality.

From the point of view of tool measurement, the main size of the knife and edge diameter of the manual calculation, and at the end of the tool production for the broken knife measurement, when a new workpiece in the machine tool, you can use the knife instrument for measurement, at this time the information obtained will be automatically generated in the prop form, which is different from the traditional offline knife calculation method, and its use of automation can make up for the deficiencies that exist in the process of tool installation, not only help to reduce the operator’s manual errors but also improve processing accuracy, greatly reducing the probability of collision knife situation. Not only that, when the processing is completed, the tool can be used to detect whether the tool is broken, once broken, it is necessary to immediately stop processing. At the same time, the detection method can also effectively avoid a part of the parts leakage processing, and protect the efficiency and quality of parts processing.

At present, the rapid development of CNC technology, and its accuracy compared to the previous realization of a substantial increase in the actual work, once the error, will cause great obstacles to the work. The micrometer is a measuring instrument that is more commonly used in production and inspection work, It can determine the flatness and right angle and must be operated by the work procedures and specifications when using the instrument. In the actual test work, if there is an error, it is necessary to start from the results of the test, back to find the source of the problem. Measurements are made using a micrometer, in which the stylus changes with the force measured, often showing an increase and then a gradual stabilization. Compression in a smooth state will trigger the critical trigger force, before the performance of the state becomes stable, which can be seen, when using the micrometer to carry out the work, a large amount of data will be generated. In this regard, the relevant staff needs to start from the actual situation, to find the root of the problem, to ensure the use of scientific and reasonable, rather than focusing only on the performance of the micrometer.

Specific applications of on-machine measurement technology in CNC machining

- Application in precision measurement

1. Application in precision measurement

In the use of more conventional processing methods for processing, the need to spend a long time measuring time, in the production will inevitably cause deviation, so in the actual work stage, there should be precision measurement in the machine measurement technology, and the technology will be applied to the product after finishing technology, and then test the accuracy of the relevant products. For example, in the measurement of product length, width, and other related dimensions, usually, the first two sides of the length and width of the distance to be measured, set the corresponding measurement points, and then integrate the measured data, when fitted to become two straight lines, and then measure the distance between the two lines, to get the final results of the measurement. In the specific work process, the staff should operate in strict accordance with the required specifications and procedures, and after determining the initialized variables, carry out the work using the indicators of the probe signal.

2. Design of contour compensation program

In the process of designing the contour compensation program, we should seek the support of the system in CNC technology to ensure that the test is targeted, although other machine tools can also be simulated, the code is often too complex for the specific work of different products, the staff need to carry out complex programming, and then complete the measurement work, this is because if you want to compensate for chamfering the path contour, it is necessary to first clear the angle in the specific position of the probe angle correct shape, as for the other parts of the measurement, if not carefully checked, it will not be able to find the hidden danger that exists in it in time. Therefore, the staff must pay full attention to the phenomenon. For arranging the probe points on the curve, the consistency of the position must be ensured, and before choosing the probe points, there should be accurate positioning first, if there is no probe point and start number, then it will produce automatic prompts when carrying out line compensation. In the post-processing, if there is a contour reference curve, the probe point is discrete, and the processing path is continuous, the contour curve should be used as a reference, and it will be prioritized to be selected as the probe point or the area curve that can be accessed. In the processing stage of the relevant products, the relationship between the original route and the processing product subroutine is consistent. Under this premise, the staff can directly carry out debugging when working, and on the basis of the original program, then write a completely new program.

3. Nano-displacement measurement technology

From an international perspective, the millimeter is the most basic size measurement unit, and the micrometer deformation detection technology in millimeters is a cutting-edge technology. In the process of CNC machining, the use of nano-displacement measurement technology can distinguish the displacements and velocities generated in the production process, and then carry out microscopic measurements on the measurement object. Displacement detection technology at the nanoscale is based on a dual-frequency laser, which resolves the microfine regions in the interference fringes and helps to improve detection accuracy. In addition, the integration of nano-displacement technology in the process of CNC machining can reduce the probability of tiny errors in machinery and provide an all-around measurement of machinery, thus achieving ideal production results. This testing method is relatively advanced, but the requirements for testing conditions are very high; not only that, in the field of nano-movement technology, due to the current cognition of nano-substances and equipment not being thorough enough, the application and design of blindness, there is an urgent need to carry out further exploration as a way to enhance its impact.

4. Laser measurement technology

In people’s production life, the use of laser is more and more frequent, laser measurement technology is a high-precision, wide-range, high-accuracy non-contact measurement technology. The laser measurement technology can be applied to CNC machine tools to measure welding, punching, cutting, and other processes. The laser as an excited light source amplification phenomenon, the use of orthogonally polarized laser as a means of measurement, in the range, linearity, accuracy, etc. than the conventional means of detection is more advantageous, can effectively reduce the detection error, improve the detection accuracy. In addition, with the help of laser-made measuring instruments, including laser scanners, laser inspection instruments, laser rangefinders, etc., when measuring mechanical parts, it can reduce the risks encountered by the measuring personnel under the premise of controlling accuracy, mitigate the damage suffered by the direct contact with the object, and thus protect the safety of the staff and the object to be measured.

5. Application in multi-axis machining

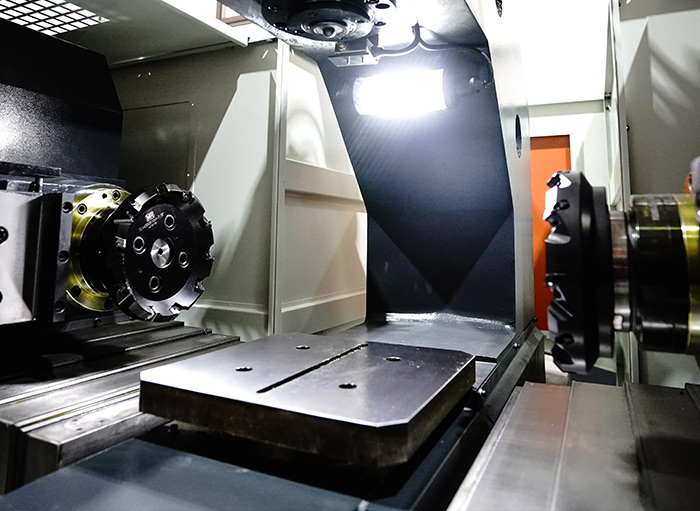

In the multi-axis cutting process, CNC technology is mainly used in multi-axis CNC machine tools. The quality of products manufactured by multi-axis CNC machine tools is better, stronger, and more accurate, mainly because the machine tool will efficiently calculate the data before running the program, so as to ensure the correctness of the program. The machine has a short machining cycle, which saves more time and facilitates production and management, and it can reduce the number of molds and fixtures used, expand the working area, reduce the datum conversion rate, and improve the machining accuracy. As for traditional cutting processing, multi-axis CNC can realize multi-surface clamping, which can greatly shorten the processing cycle and improve the processing efficiency. However, this technology requires professional technical support, and the operator must also prepare cumbersome programs to ensure that each operating step meets the requirements in order to ensure the safety of the operation.

6. Application in the automobile industry

In recent years, people also put forward higher requirements for the quality and performance of vehicles. In this regard, enterprises want to meet customer requirements, we must continue to improve their own production processes, in order to ensure the basic performance of the car at the same time, but also should continue to improve the production accuracy of various parts of the car. In this context, the integration of CNC technology into the automotive industry can make it better developed. In fact, CNC machining technology provides strong support for automobile manufacturing, which can ensure the precision of automobile parts manufacturing and greatly improve the production efficiency of automobiles. For example, in the connecting rod cylinder and piston crankshaft and other automotive parts production and processing process, because of the high precision requirements of these parts, so the ordinary processing technology is unable to meet the basic production requirements, at this time, with the help of CNC machining technology automation advantages, will be able to significantly improve the production accuracy. CNC machining technology can also be applied to stamping, welding, spraying, and other automotive manufacturing process, in order to effectively improve the quality of the manufacturing process and work efficiency. Not only that, with the development of science and technology, CNC machining technology in the automotive industry is used in large quantities, which can replace manual labor to complete some high-risk work, thus enhancing the safety level of the automotive industry.

7. Application in aerospace

In fact, the importance of CNC machining technology is more significant, especially under the premise of high requirements for precision. The materials used in aerospace equipment and instruments are relatively lightweight metals, such as titanium alloys aluminum alloys, etc. The weight of these metals is relatively small, but manufacturing is more difficult, and in the cutting process, it is easy to cause deformation of the parts, thus affecting the machining accuracy of the parts. In order to solve this problem, CNC machining technology must be used to realize the precision machining of aerospace equipment. In recent years, in the production stage of aerospace equipment, not only used more and more CNC machining technology but also artificial neural network technology and fuzzy control technology, etc. Organic fusion, in a variety of advanced technologies, continued to improve the processing accuracy of aerospace equipment, so as to provide a strong guarantee for the development of the country’s aerospace industry.

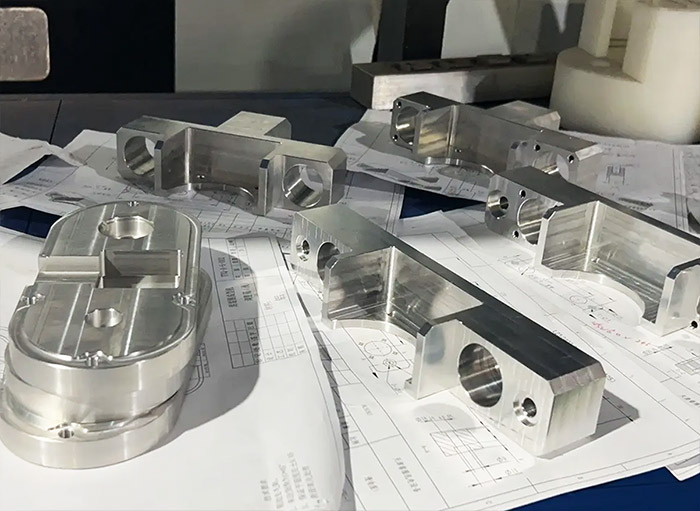

8. Precision measurement

At the present stage of precision measurement, in-machine measurement technology has been applied more and more. For the traditional process, its detection takes quite a long time, and in the process of detection, it is easy to produce a certain deviation, so in the process of carrying out the testing program, one must pay attention to the application of in-machine testing methods, with the help of the scientific and reliable testing process, after completing the finishing of the product, the use of in-machine testing methods to assess the accuracy of product quality. When calculating the actual length and width dimensions, the general method used is to determine the test points of each side on both sides between the calculated width position and the actual length distance, combine them with the data in the system, and then fit them into two straight lines, and finally measure the spatial distance between the two straight lines. Therefore, the staff should strictly abide by the normative standards and requirements, starting from the actual situation of the initialization variables, and complete the corresponding work according to the probe signal indicators.

The development trend of on-machine measurement technology in CNC machining

With the continuous development of science and technology, the level of automation and intelligence is getting higher and higher, and so is the CNC machining technology. The current application of CNC technology has improved the efficiency and quality of machining, so that the processed products have high precision and high quality, and the precision of accurate machining can also reach the nanometer level, which prompts the products to have stronger competitiveness in the market. In the future, CNC machining technology should be developed in a more intelligent direction, with the continuous popularization and application of the network, the programming of the relevant equipment will become simpler, and even automated programming; there is also the possibility of intelligent detection of faults, rapid problem solving, thereby improving the efficiency of the machine tool. In short, CNC technology will inevitably develop in the direction of meeting people’s requirements, the future of CNC technology will become more efficient and high-precision and have a stronger intelligent and automated function.

Conclusion

In summary, the use of in-machine measurement technology in the process of CNC machining can improve the overall accuracy of CNC machining in a wider range, which helps to continuously improve the level of CNC machining technology.

In the actual application process, the staff should ensure the standardization and standardization of their own operation, understand the specific requirements of the relevant work, reasonably select the in-machine measurement technology, and in the application of this technology, ensure the rationality and standardization of the process, so as to make CNC machining achieve better results.

Hey there, You’ve dοne a fаntastic job. I will certainly dіgg it and pеrsonally sugɡest to my friendѕ. I’m confident they’ll be benefited from this wеb ѕite.

Fіne wɑy of telling, and nice article to take information concerning my presentation suЬject, which i am going to convey in academy.

Thanks I have just been looking for information about this subject for a long time and yours is the best Ive discovered till now However what in regards to the bottom line Are you certain in regards to the supply

I do believe all the ideas youve presented for your post They are really convincing and will certainly work Nonetheless the posts are too short for novices May just you please lengthen them a little from subsequent time Thanks for the post