Automotive Die Casting and Casting Aluminum Alloys

Aluminum alloy has a series of excellent performance and highly efficient energy saving and environmental protection effects, the application of aluminum alloy in automobiles and motorcycles is more and more, and the proportion in the structure of the material used is also increasing year by year. Reducing the car’s mass is one of the main ways to expand its application. To greatly reduce the weight of the car, it is necessary to adopt aluminum alloy materials to replace the steel parts such as the body (about 30%), engine (about 18%), transmission system (about 15%), running system (about 16%) and wheels (about 15%), etc, which account for a large proportion of the weight of the car.

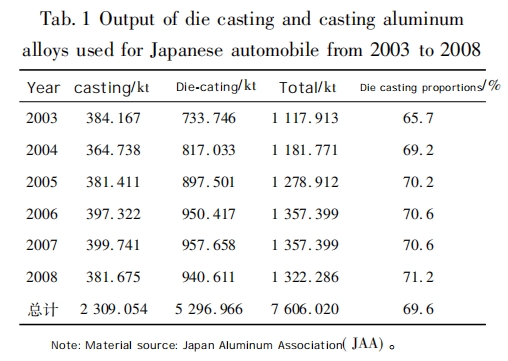

Among the aluminum alloys used in automobiles, die-casting aluminum alloys and other casting aluminum alloys account for about 80%, and processed aluminum materials (plates, strips, foils, tubes, rods, profiles, wires, forgings, powders, and pastes) account for only about 20%, and with the rise in the use of aluminum plates and strips for bodywork, the percentage accounted for by aluminum materials will increase year by year, but the rate of increase will not be large. In the casting products with aluminum alloy, die casting production accounted for about 70% of the casting products production, so die casting aluminum alloy in the automotive aluminum accounted for 55%, of course, in each country in the use of aluminum in this proportion will be different, but are in the range of 54% ~ 70%. 2003 ~ 2008 Japan aluminum castings and die casting consumption are shown in Table 1.

The use of aluminum alloy instead of cast iron production in automobile parts of history can be traced back to the 1940s, when a few European automobile factories, such as Italy’s Fiat developed aluminum alloy intake pipes and cylinder heads and began to produce a small number of. 1950s, Australia introduced the British company’s low-pressure casting technology to produce automobile aluminum castings. At the same time, the Federal Republic of Germany made further improvements to the low-pressure casting technology to produce aluminum alloy parts with complex structures. The United States General Motors also began mass production of car aluminum castings, such as air-cooled cylinder heads, crankcases, engine covers, etc. After the 1960s, due to the development of high-pressure die-casting technology, aluminum alloys based on the application of light metals in the automobile increased greatly, laying the foundation for the modern automobile industry to widely use aluminum castings to reduce the car’s weight.

Nearly 20 years, the world automobile industry’s aluminum castings application in increased, according to statistics, the world’s total production of aluminum castings each year by more than 3% of the rate of growth, and in the total production of aluminum castings, 60% ~ 70% of the aluminum castings used in automobile manufacturing, so that the world’s aluminum castings of production and application of the automobile manufacturing industry development has produced a close link. The automobile industry in the application of aluminum castings and the development of Japan’s most prominent. In the early 1970s, many Japanese automobile companies carried out and expanded the application of aluminum alloy in automobile engine research, began to widely use aluminum castings instead of cast iron to produce intake pipe, and cylinder heads, and began a small amount of production of aluminum engines. In recent years, in the development of aluminum castings and plastics applications, Japan has been at the world’s advanced level, the Japanese car has always been compact, comfortable, lightweight, good economy, as well as safe and reliable, and occupies a certain share of the European and American markets.

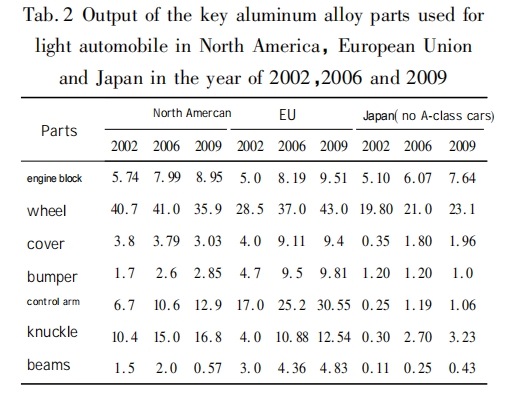

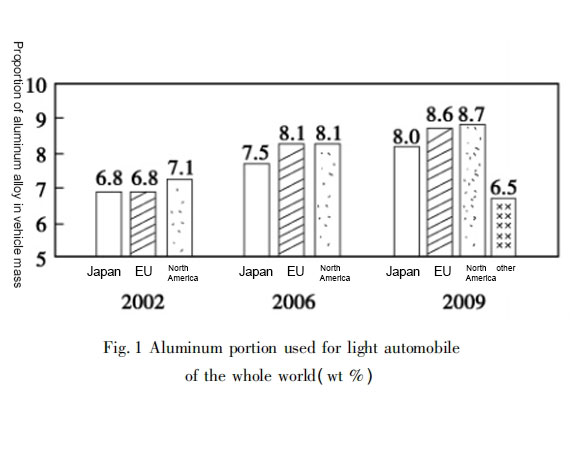

Table 2 for North America, the European Union, and Japan in 2002, 2006, and 2009, the production of key aluminum alloy parts for light-duty vehicles; and the proportion of global aluminum content of light-duty vehicles is shown in Figure 1 [1].

1 The proportion of various automotive aluminum materials

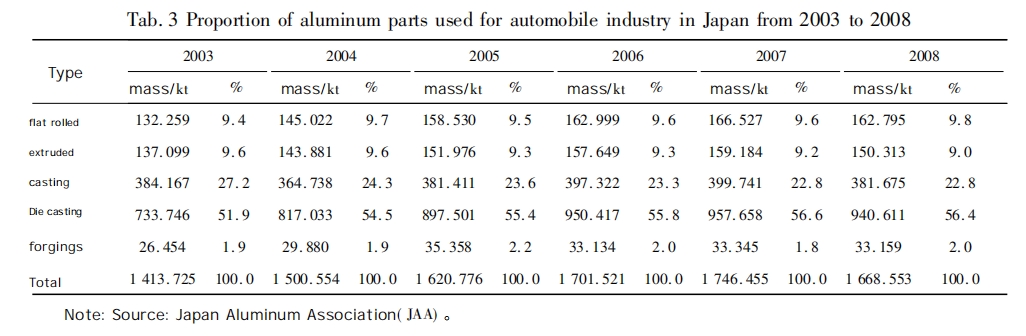

In contemporary automobile manufacturing all kinds of aluminum have been applied, especially die casting and casting of the most widely used, especially the largest amount of recycled aluminum alloy, the world’s annual production of casting aluminum alloy of about 80% used in the manufacture of automotive die casting and other castings. 2003 ~ 2008 Japan’s automobile industry on demand for aluminum and various varieties of aluminum accounted for the proportion of Table 3. 2003 ~ 2008 in 6 years, die casting and casting of aluminum alloy, and the proportion of aluminum in the automobile industry. From 2003 to 2008, the average proportion of die casting and casting was 79.1% in 6 years, but with time, the proportion of die casting and casting use slightly decreased, for example, in 1983, this proportion was 88.4%, in 1993, it fell to 81.9%, and in 2003, it was reduced to 79.1%, and then to 2008, it is almost unchanged, and then after that, the decline will be a little bit bigger.

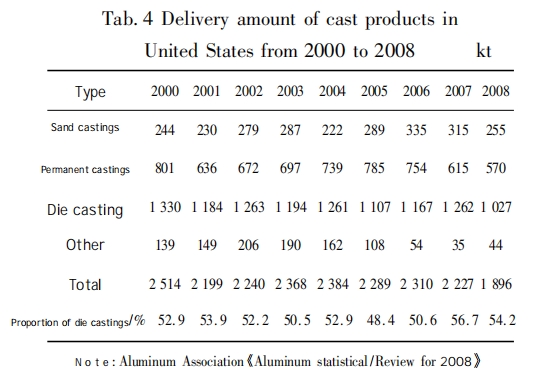

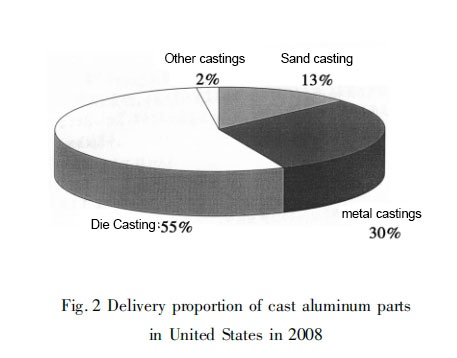

2000 ~ 2008 U.S. cast aluminum alloy shipments are shown in Table 4, and Figure 2 shows the United States in 2008 the proportion of various types of aluminum castings shipped. From these data, aluminum alloy die casting in the United States accounted for a much lower proportion than Japan’s, about 25 percentage points or more, but still showing an upward trend, the proportion of the second few years of the new century than the first few years of the proportion of some higher.

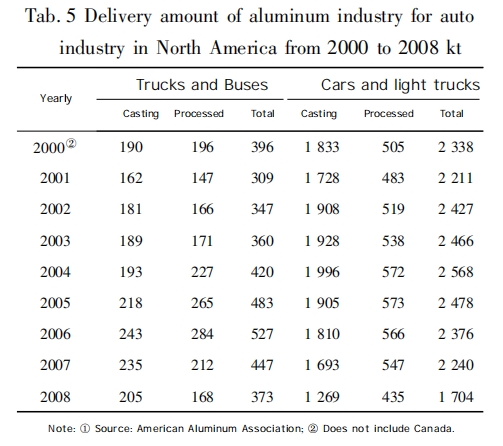

North American (U.S. and Canada) aluminum industry shipments to the automotive industry from 2000 to 2008 are shown in Table 5.

2 Cast and die-cast aluminum alloys

Among the aluminum used in automobiles, casting products (die casting and casting) account for 74% to 80%, of which Japan’s is the highest, Germany’s is the lowest, and China’s and other countries and regions are in between, while die casting in casting products account for 53% to 70%, of which Japan’s is the highest at 70% and weak, the United States is low at 55%, and China’s and other countries and regions are in the middle.

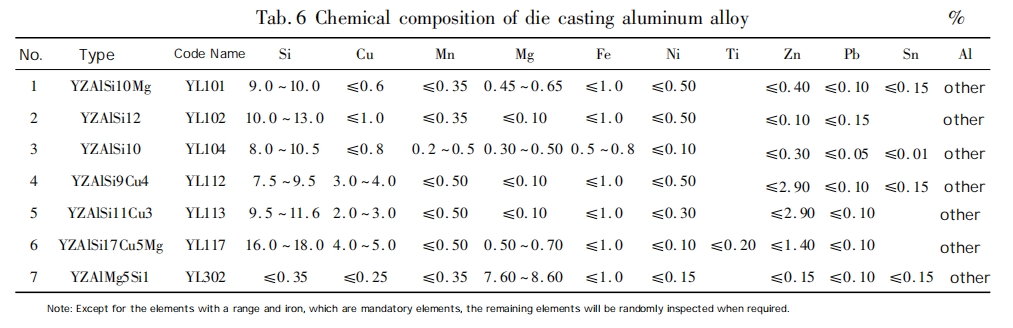

- 1 China’s die-casting aluminum alloy composition

According to the GB / T 15115-2009 standard, China’s die-casting aluminum alloy chemical composition is shown in Table 6.

2.1.2 Performance and other characteristics

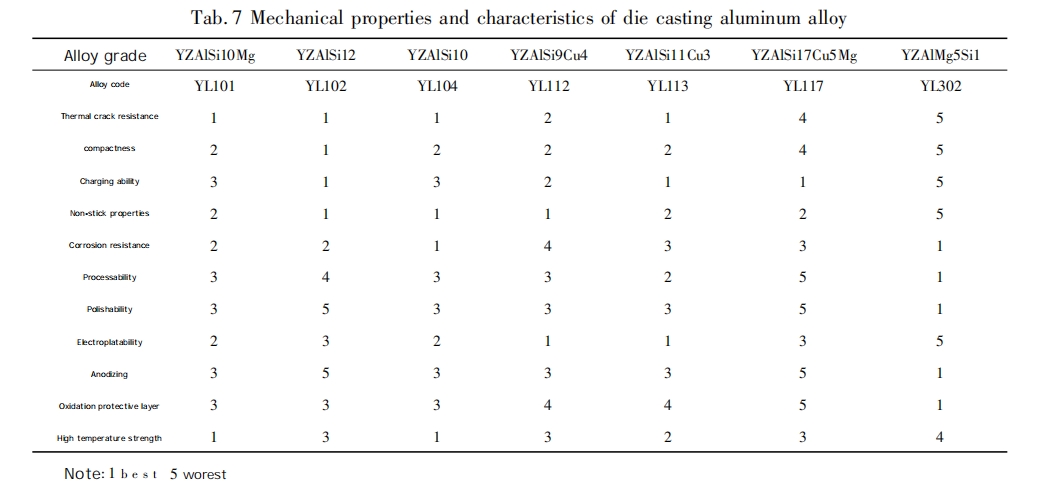

The evaluation of the performance and other characteristics of each die-casting aluminum alloy in GB /T 15115-2009 standard is shown in Table 7, in which YL101, YL104, YL112, and YL113 alloys have better comprehensive performance, while the other alloys have poorer performance.

2.1.3 Characteristics and applications of die-casting aluminum alloys

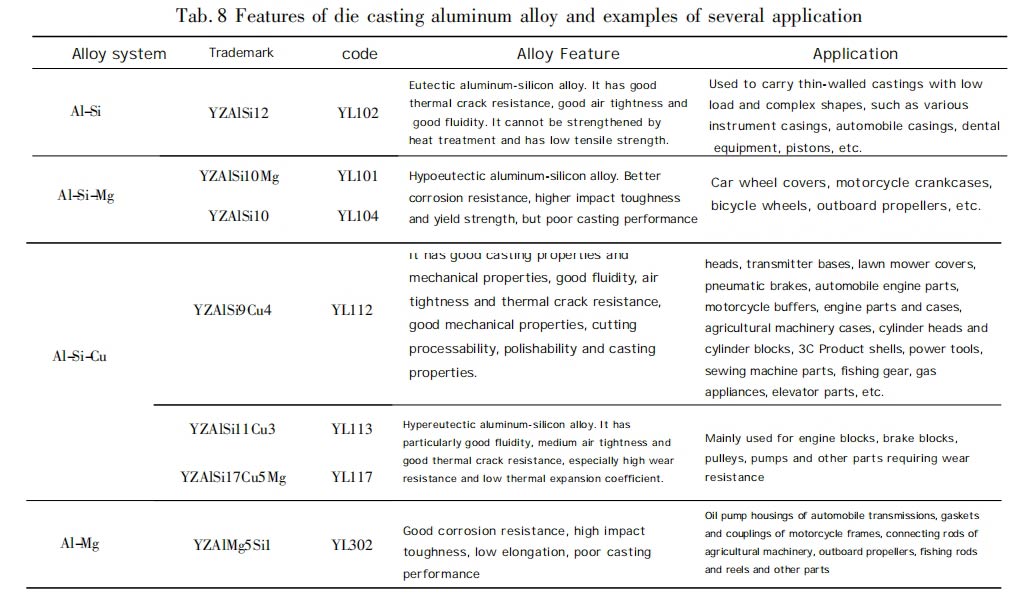

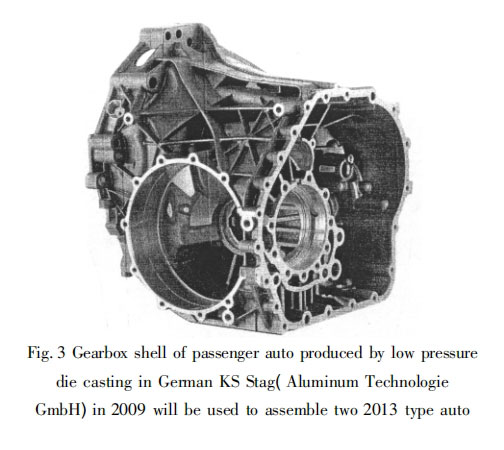

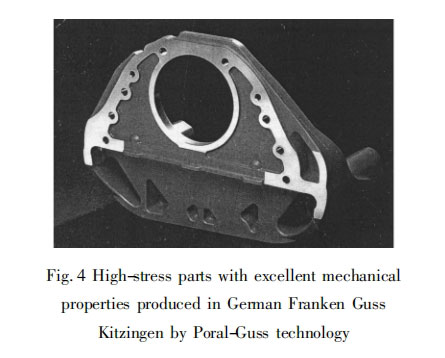

GB /T 15115-2009 in the form of the informative appendix to each die-casting aluminum alloy characteristics for a brief description, and examples of its typical practical applications (Table 8), automobile and motorcycle dozens of parts, such as wheels, gearboxes, cylinder heads, engine parts, pulleys, pistons, oil pump housing, etc. are die-cast with this type of alloy (Figure 3, Figure 4).

2.2 Japanese die-cast aluminum alloys

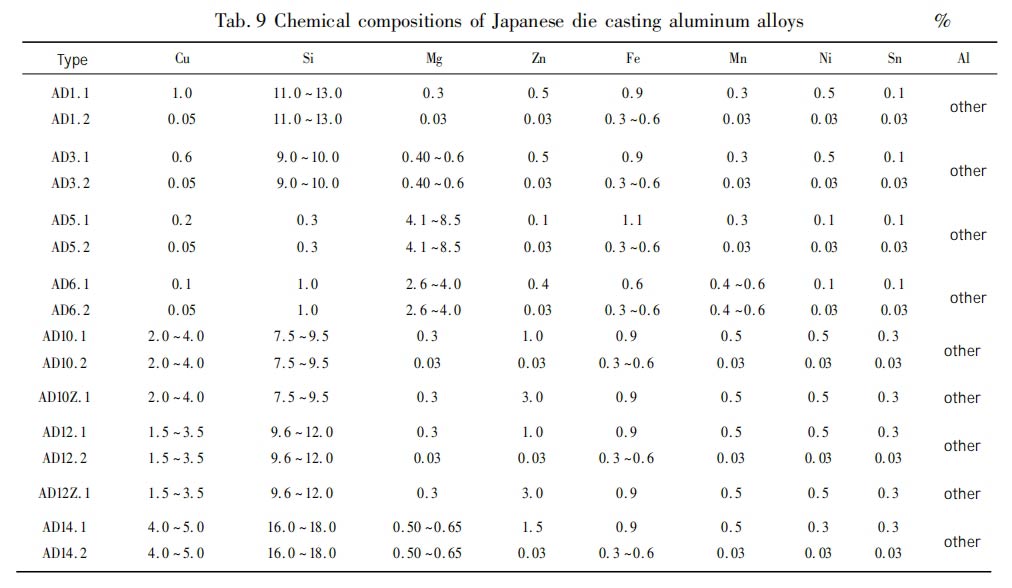

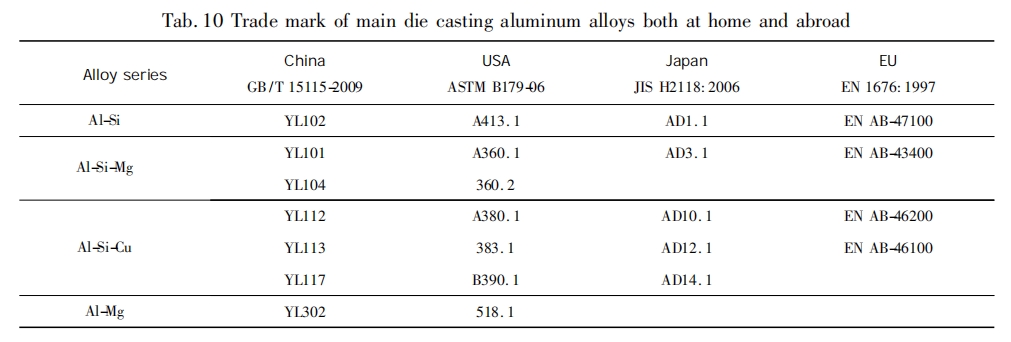

The chemical composition of Japanese die-cast aluminum alloys is shown in Table 9 (JIS H-2118), and the main die-cast aluminum alloy designations for several countries are shown in Table 10.

- 3 Casting Aluminum Alloys in China

According to GB /T 1173-1995 standard, the casting aluminum alloy code by the letters “Z”, and “L” (they are “casting”, and “aluminum” in the first Chinese pinyin) The code of cast aluminum alloy consists of letters “Z”, “L” (they are the first letters of “cast” and “aluminum” in Chinese pinyin respectively) and the three Arabic numerals after them. the first number after ZL indicates the alloy series, of which 1, 2, 3, and 4 indicate the alloys of Al-Si, Al-Cu, Al-Mg, and Al-Zn series respectively, and the second and the third numbers after ZL indicate the sequence number.

The second and third numbers after ZL indicate the sequence number. High-quality alloys have the letter “A” appended to the numbers.

Alloy casting method, metamorphic treatment code for.

S – sand casting

J — metal mold casting

R — Investment mold casting

K — shell casting

B – Metamorphic treatment.

The alloy state designations are.

F — as-cast; T1 — artificial aging; T2 — artificial aging; T3 — artificial aging

T1—artificial aging; T2—annealing; T3—annealing; T4—annealing

T2—Annealed; T4—Solid solution treatment plus natural aging; T5—Solid solution treatment plus natural aging

T4—solid solution treatment with natural aging

T5 — solid solution treatment plus incomplete artificial aging; T6 — solid solution treatment plus artificial aging

T6—-Solid solution treatment plus complete artificial aging; T7—-Solid solution treatment plus artificial aging; T8—-Annealing; T9—-Annealing

T7—-Solid solution treatment plus stabilization; T8—-Solid solution treatment plus artificial aging; T9—-Solid solution treatment plus artificial aging

T8 — solid solution treatment plus softening treatment.

- 3. 1 Chemical composition

The chemical composition of cast aluminum alloy is shown in GB/T1173-1995 and the permissible content of impurities is shown in GB/T1173-1995.

Al-Si alloys that need to be densified are treated with sodium (containing sodium salt), and other densifying agents or densification methods are allowed without reducing the performance of the alloys. When used in the marine environment, w(Cu) in ZL101 alloy ≤0.1%. The silicon content of ZL203 alloy is allowed to be w(Si) = 3.0% when casting with a metal mold.

For ZL105 alloy w(Fe) > 0.4%, the manganese mass fraction should be more than half of the iron. When ZL201 and ZL201A alloys are used for parts operating at high temperatures, w(Zr) = 0.05% to 0.20% should be added.

To improve the mechanical properties, ZL101, and ZL102 alloys are allowed to contain yttrium w ( Y ) = 0.08% ~ 0.20%; ZL203 alloys are allowed to w ( Ti ) = 0.08% ~ 0.20%. In this case, their iron content w(Fe) ≤ 0.3%.

Aluminum alloys in contact with food: beryllium is not allowed; w(As) ≤0.015%; w(Zn) ≤0.3%; w(Pb) ≤0.15%.

When the sum of impurities is used to express the impurity content, the mass fraction of each unlisted element should not be more than 0.05% if not specified.

- 3. 2 Mechanical properties

Mechanical properties of casting aluminum alloy are shown in GB /T1173-1995 standard, the mechanical properties are tested by single casting specimen, the diameter of the specimen is ( 12 ± 0.25) mm, and the marking distance is five times the diameter, or the specimen can be tested by cutting 1-3 fundamental specimens from the same furnace casting.

- 3. 3 Solution heat treatment of cast aluminum alloys

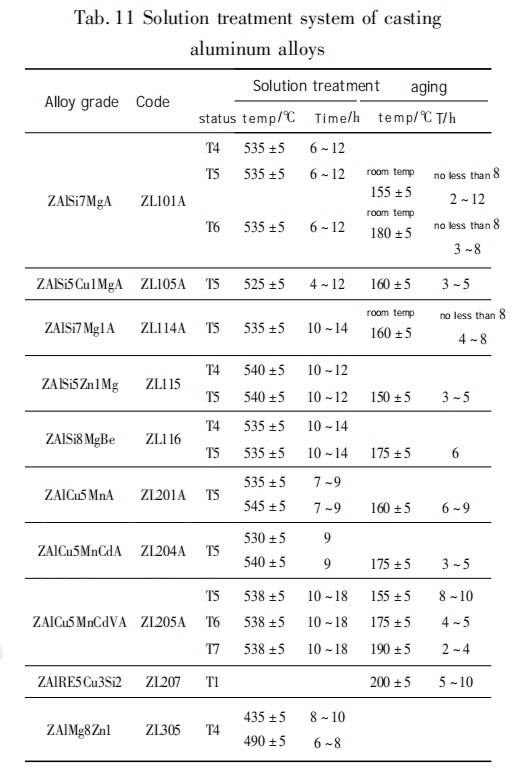

Cast aluminum alloy solid solution treatment specifications are shown in Table 11.

When solid solution treatment, the loading temperature is generally below 300℃, and the rate of temperature increase (to solid solution temperature) is 100℃/h. If there is a need for stage holding during solid solution treatment, the temperature should be kept at a constant level. Solid solution treatment, such as the need for stage insulation, between the two stages is not allowed to stay cool, and needs to be directly up to the second stage temperature. After solid solution treatment, quenching transfer time control in 8 s ~ 30 s (depending on the type of alloy and parts), quenching medium water temperature from the manufacturer according to the alloy and the type of parts, aging is completed cooling medium for room temperature air.

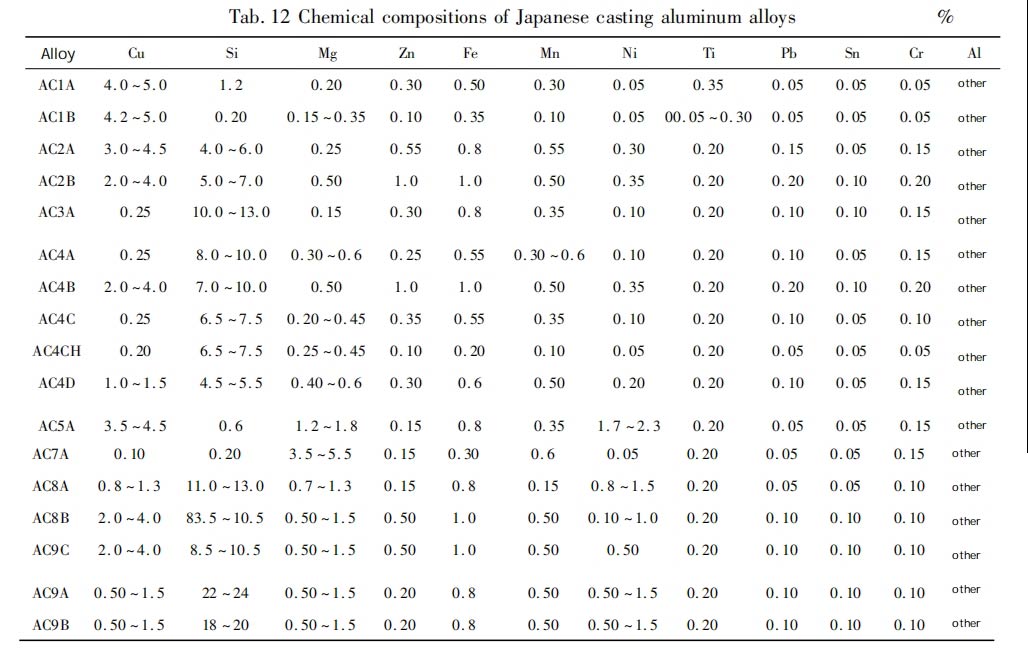

- 3. 4 Japanese and German casting aluminum alloy chemical composition of Japanese aluminum alloy chemical composition is listed in Table 12 (JISH5202).

- 4 High-strength automotive casting aluminum alloy

Automotive lightweight is an important issue in the development of contemporary automobiles, its basic requirements are: to ensure that the quality and function of the car will not be affected under the premise of minimizing the quality of parts and components, reducing fuel consumption, reducing emissions pollution; in the automobile to reduce the quality of the reduced fuel consumption, reduce emissions at the same time, and strive to seek its high output power, high responsiveness, low noise, low vibration, good maneuverability, High reliability and high comfort, etc.; In the automobile lightweight at the same time, the price is best to decline or remain at a reasonable level, with commercial competitiveness, that is, the car’s lightweight technology must take into account the quality, performance, and price.

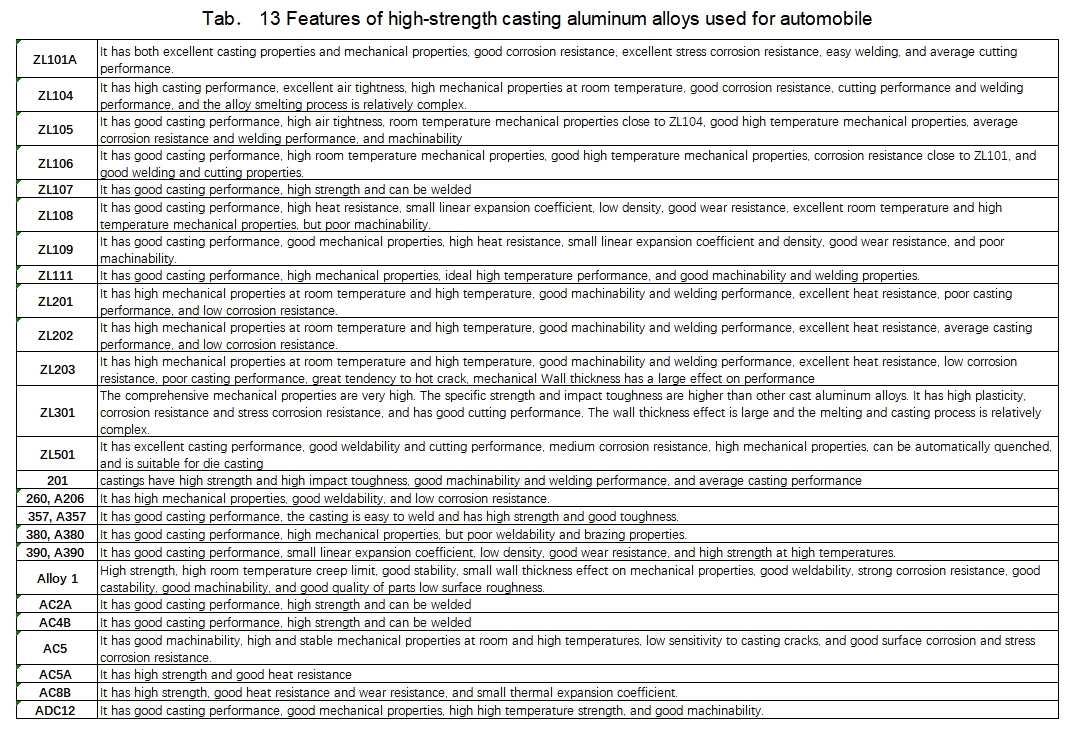

The practice has proved that as much as possible to use of high-strength aluminum alloy manufacturing automotive parts is to achieve one of the effective measures of automotive lightweight, high-strength automotive casting aluminum alloy characteristics are shown in Table 13

One comment

Leave a Comment

You must be logged in to post a comment.

Your positive energy acts like a potent lead generation strategy, motivating the entire team!