Briefly introduce what is a milling cutter

A milling cutter is a rotating cutting tool used in milling machines or machining centers to remove material from a workpiece. It consists of one or more cutting edges, usually made of high-speed steel (HSS) or carbide, that rotate and cut into the workpiece. Milling cutters can come in a variety of shapes and sizes, each designed for a specific purpose and application. It is an important tool in manufacturing blades and is widely used in CNC machining services.

What feature is the milling cutter?

Milling cutters are versatile tools used in machining processes to remove material from a workpiece. They come in various types and sizes, each designed for specific applications. Here are some key features of milling cutters:

Material Composition:

Milling cutters are typically made from high-speed steel (HSS), carbide, or sometimes ceramic materials.

Carbide cutters are popular for their hardness and durability, providing longer tool life and higher cutting speeds.

Cutting Edges:

Milling cutters have multiple cutting edges, which can range from one to more than a dozen, depending on the type of cutter. The cutting edges can be on the periphery, the end face, or both, allowing for various cutting actions.

Geometry:

The geometry of the cutter influences its cutting capabilities. Common geometries include square, ball nose, corner radius, and chamfer, each suited for specific tasks.

Different cutter geometries are chosen based on the desired surface finish, material type, and machining operation.

Shank Type:

The shank is the part of the milling cutter that is gripped by the machine spindle. Common shank types include straight shank and tapered shank (such as Morse taper or R8 taper).

Coating:

Some milling cutters may have coatings to enhance their performance. Common coatings include TiN (titanium nitride), TiCN (titanium carbonitride), and TiAlN (titanium aluminum nitride), which provide improved hardness and wear resistance.

Helix Angle:

For certain cutters like end mills, the helix angle (the angle between the cutting edge and the axis of rotation) affects chip evacuation, cutting forces, and surface finish.

Flutes:

Flutes are the grooves or channels on the milling cutter that help evacuate chips from the cutting area. The number of flutes can vary, and the choice depends on factors such as material type and machining conditions.

Application-Specific Features:

Some milling cutters are designed for specific applications, such as keyseat cutters for cutting keyways, T-slot cutters for milling T-shaped slots, and thread mills for machining threads.

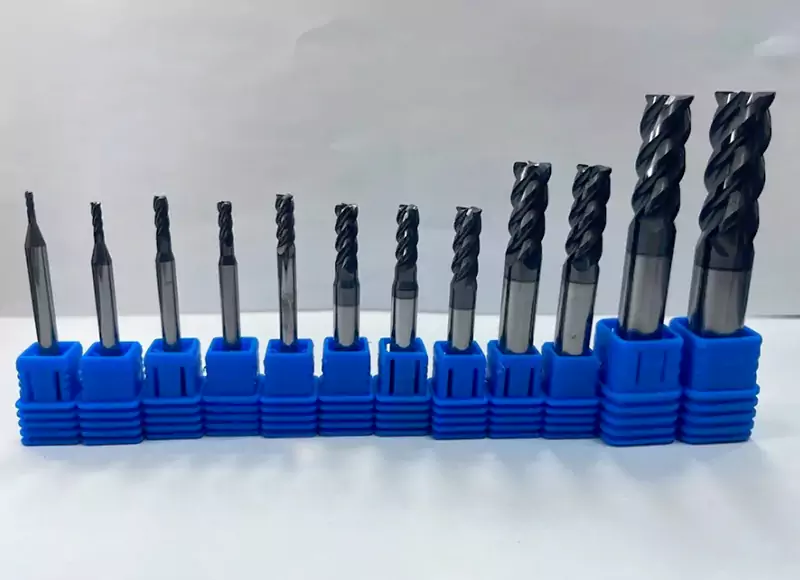

Size and Diameter:

Milling cutters come in various sizes and diameters to accommodate different machining requirements. The size and diameter influence the depth of cut and the overall stability of the cutter.

Coolant Channels:

Some milling cutters may have built-in coolant channels to facilitate the efficient removal of heat generated during the machining process.

Understanding these features is crucial for selecting the right milling cutter for a specific machining task, ensuring optimal performance and tool longevity.

Common types of milling cutters include:

End Mill:

An end mill is a versatile milling cutter with cutting edges on both the end face and the sides, designed to remove material from a workpiece. Common types include square end mills for general applications, ball nose end mills for 3D profiling, corner radius end mills for rounded corners, and chamfer end mills for creating chamfered edges. The number of flutes, helix angle, and coatings vary, influencing chip evacuation, tool rigidity, and wear resistance.

Face Mill:

A face mill is a milling cutter designed for removing material from the face of a workpiece. It features cutting edges on the face as well as the periphery, allowing efficient material removal in both axial and radial directions. Face mills are commonly used for facing large flat surfaces, producing smooth finishes. They come in various sizes and configurations, with multiple inserts or cutting edges. The tool’s geometry and coatings influence its performance in terms of speed, chip evacuation, and wear resistance. Face mills are essential in manufacturing processes for industries such as metalworking, where flat surface machining is prevalent.

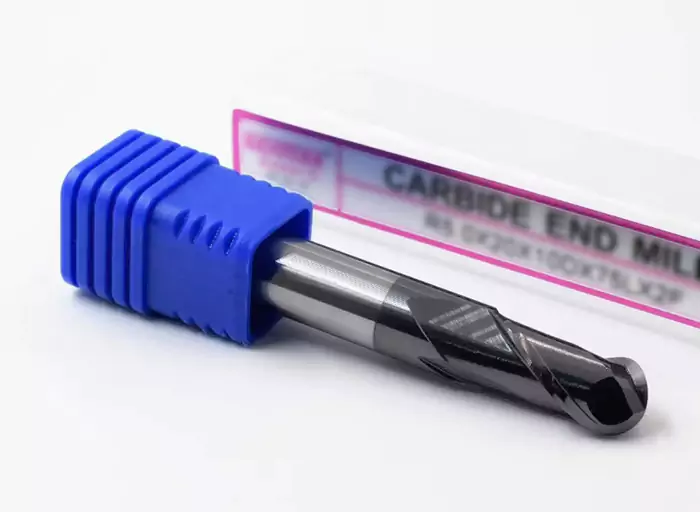

Ball Nose Cutter:

A ball nose cutter is a specialized milling tool with a rounded end designed for intricate 3D contouring and profiling. Featuring a spherical tip, it allows for smooth and precise carving of curved surfaces in materials like metal or wood. The unique design minimizes cutting forces and reduces the risk of workpiece damage. Ball nose cutters are commonly used in sculpting, engraving, and machining applications where detailed and contoured surfaces are essential. The size, radius, and number of flutes in the cutter impact its performance, making it a valuable tool in industries such as aerospace, automotive, and mold-making for intricate machining tasks.

Shell Mill:

A shell mill is a milling cutter characterized by its large diameter and cutting edges on its periphery, primarily used for high-speed milling of large flat surfaces. It resembles a hollow shell, allowing for efficient material removal across expansive workpieces. Shell mills come in various sizes, accommodating diverse applications in industries like manufacturing and metalworking. The tool’s design provides stability and rigidity during operation, ensuring consistent and precise surface finishes. Commonly used with multiple inserts, shell mills are essential for facing operations and profiling large workpieces, making them indispensable in applications such as aerospace, automotive, and heavy machinery manufacturing.

Slab Mill:

A slab mill is a type of milling cutter designed for machining large, flat surfaces in a single pass. Characterized by its wide cutting edge, the slab mill efficiently removes material across expansive workpieces, enhancing productivity. This tool is commonly used in heavy-duty milling operations, such as face milling or surface milling of large components. The robust design and broad cutting surface contribute to the stability and precision required for handling significant material removal. Slab mills find application in various industries, including manufacturing, construction, and shipbuilding, where the efficient milling of extensive flat areas is essential for achieving precise and smooth finishes.

T-slot Cutter:

A T-slot cutter is a specialized milling tool designed to cut T-shaped slots or channels into workpieces, typically used in machine tables and fixtures. This cutter features a cutting head with a T-shaped profile, allowing for the creation of precise slots that accommodate T-shaped fasteners or workpiece positioning. T-slot cutters are essential in machine tool setups, enabling the secure fixation of components using T-bolts and nuts. These cutters come in various sizes to match different T-slot dimensions, offering versatility for a range of applications. Widely used in metalworking and machining, T-slot cutters contribute to the efficient and accurate construction of workholding systems.

Keyseat Cutter:

A keyseat cutter is a specialized milling tool designed for cutting keyways or slots in shafts, hubs, or other cylindrical objects. Featuring a straight or staggered-tooth design, this cutter creates precisely sized and shaped keyways, allowing for the secure fitting of keys and key stock. Keyseat cutters are vital in machinery and equipment assembly, providing a means to secure gears, pulleys, and other rotating components onto shafts. Available in various sizes and configurations, these cutters contribute to the precise and efficient machining of keyways, ensuring proper alignment and functionality in applications across industries such as manufacturing, automotive, and mechanical engineering.

Fly Cutter:

A fly cutter is a single-point cutting tool used in machining for facing and smoothing large flat surfaces. Consisting of a single cutting tool mounted on a spindle, it rotates and engages with the workpiece. Fly cutters are typically used at low speeds and produce a smooth finish across the surface. They are commonly employed for facing operations on milling machines and are advantageous for their simplicity and cost-effectiveness. Despite their single-point design, fly cutters are capable of achieving accurate finishes, making them suitable for various applications in metalworking and woodworking where precision flat surfaces are required.

Milling cutters are crucial in various CNC machining processes, allowing for precise and efficient material removal. The selection of the appropriate milling cutter depends on factors such as the type of material being machined, the desired surface finish, and the specific machining operation.