Development and trends of 5-axis linkage CNC machine tools

CNC machine tools as equipment manufacturing industry “industrial mother machine”, is to promote the development of national industrial strength and accelerate the construction of manufacturing power of the important strategic equipment, representing the highest level of machine tool manufacturing industry 5-axis linkage CNC machine tool system, is a measure of a country’s ability to manufacture complex and precision parts of the level of technology and automation of national production equipment.

An important standard of the technical level of national production equipment automation. With the development of industry, five-axis linkage CNC machine tools are considered to be the most important high-precision machining equipment for aerospace, marine, military, classified instruments, high-precision medical equipment, and other areas of processing and manufacturing key components.

As a difficult, widely used, computer control, high-performance servo drive and precision machining technology in one of the CNC machine tool technology, 5-axis linkage CNC machine tools and the traditional three-axis CNC machine tools, compared with irreplaceable advantages:

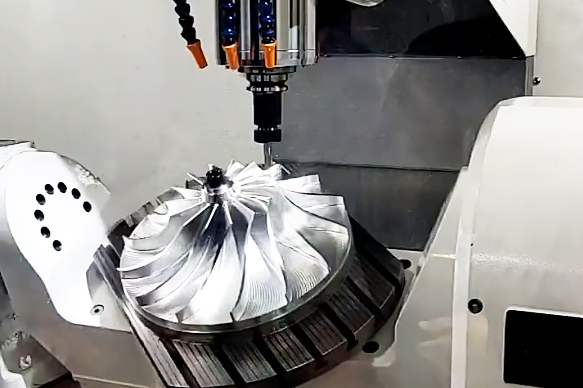

(1) five-axis linkage CNC machine tools can be processed three-axis CNC machine tools can not process the complex shape of the workpiece, the machining process can effectively avoid tool interference. For example, in the processing of aerospace applications such as impellers, blades whole leaf disks, and other parts, five-axis machine tools can be processed using a shorter tool to enhance the system rigidity, reduce the number of tools, and avoid the generation of specialized tools.

(2) Compared with three-axis CNC machine tools, five-axis CNC machine tools can reduce the number of clamping, and datum conversions, and reduce the number of fixtures used to significantly improve machining efficiency and machining accuracy.

(3) five-axis CNC machine tools with high flexibility, high precision, high integration, and complete processing capabilities, can be a good solution to the aerospace, automotive, and other fields of new product development process of complex parts machining accuracy and cycle time, thus greatly reducing the development cycle, improve the success rate of new products. At present, five-axis linkage CNC machine tools have become the hot spot and focus of developing the high-grade CNC machine tool industry in various countries.

The basic structure of five-axis linkage CNC machine tools

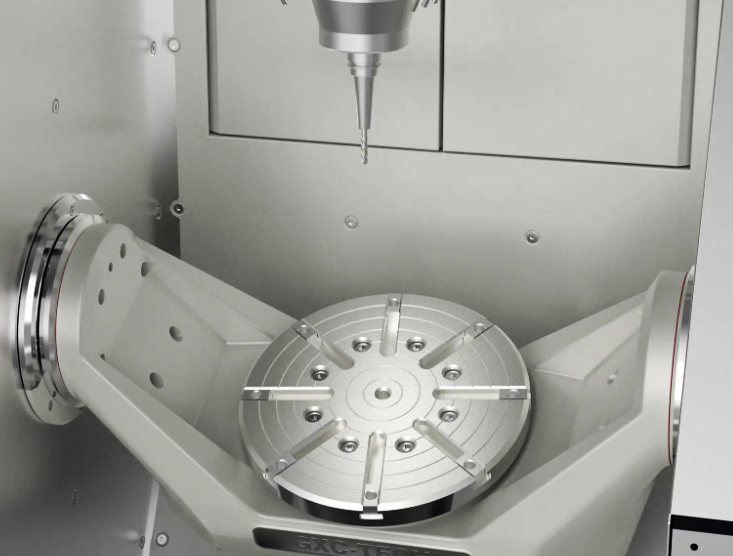

The current five-axis linkage CNC machine tools are mostly “3 + 2” structures, that is, X, Y, Z three linear axes of motion plus the X, Y, and Z axis rotation around the A, B, and C three rotary axes in the composition of two. Therefore, from the general direction of classification, five-axis linkage CNC machine tools have X, Y, Z, A, B; X, Y, Z, A, C; X, Y, Z, B, C three forms. Divided according to the combination form of two different rotary axes, five-axis linked CNC machine tools mainly have three forms: double rotary table type, rotary table plus pendulum head type, and double pendulum head type.

1.1 Double rotary table structure of five-axis linked CNC machine tools

The rotary table structure of this five-axis linkage machine tool is the double rotary table structure of A-axis + C-axis. The table set on the bed can rotate around the X-axis, defined as the A-axis and the working range of the A-axis is generally 30° to 120°. The rotary table set in the middle of the table can rotate around the Z-axis, defined as the C-axis and the C-axis can rotate 360°. Therefore, through the combination of the A-axis and C-axis, workpieces fixed on the table can be machined with vertical spindles on all five faces except the bottom face.

1.2 Five-axis CNC machine tool with rotary table plus pendulum head structure

A-axis, B-axis, or C-axis can be the rotary table and pendulum head of the machine tool, so the five-axis linked machine tool with the rotary table and pendulum head structure can realize different combinations to adapt to different machining objects. The advantage of this setup is that the spindle of the machine can realize flexible machining, and by making the table of the machine larger, the machining of large and complex workpieces can be realized.

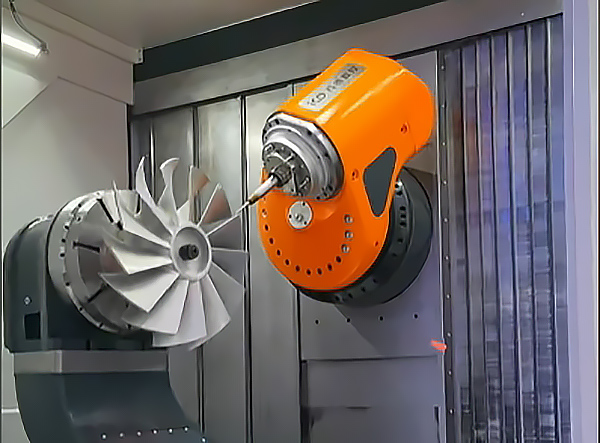

1.3 Five-axis CNC machine with double pendulum head structure

The structure of the pendulum head with a loose pull knife structure of the spindle, so the size of the double pendulum head itself should not be too small, generally in the 400mm ~ 500mm, coupled with the need for double pendulum head range of activities, double pendulum head structure of five-axis CNC machine tools with a larger machining range, generally gantry-type or gantry type of moving beams, gantry width is generally in the range of 2000mm ~ 3,000mm. At present, the more advanced double pendulum head type five-axis linkage machine tool pendulum head structure generally adopts “zero transmission” technology torque motor, “zero transmission” technology in the rotary axis of the application to solve the problem of rigidity and accuracy of the transmission chain of the main technical routes.

The current state of research in various countries

Five-axis linkage CNC machine tool research status of each country Currently, 5-axis linkage CNC machine tool research abroad mainly in Europe and the United States as the representative of developed countries, Japan, these countries represent the highest level of today’s five-axis linkage CNC machine tool development. With the technological progress and social requirements for high-grade CNC machine tools continuing to improve, the famous five-axis CNC machine tools large-scale manufacturing company’s CNC technology is to high-speed, high-precision, intelligent, composite, high-reliability, and green direction of development.

Germany’s SycoTec (SycoTec) 4015DC-R-HSK63 high-speed precision electric spindle was applied to five-axis CNC machine tool machining centers, so that the machine tool’s machining range from the original 0 ~ 24,000r/min to expand to 0 ~ 100,000r/min five-axis ultra-high-speed precision machining and the machine tool with standard HSK-63 tool holder, to achieve the standard fast, The use of standard HSK-63 tool holders on the machine enables standard quick, frictionless tool changes, shortening machine stopping times, increasing production output and efficiency, and broadening the machine’s machining range. Zimmermann company designed five-axis linked CNC machine tools equipped with M3ABC with curved guideway high-end three-axis milling head, B coordinate more than one, that is, containing A, B, C three different rotary coordinate head, the five-axis linked CNC machine tools with excellent rigidity, and relatively compact structure, because of the built-in A, B, C three different coordinate head, increasing the range of deflection. The C-axis rotation process is not restricted, which improves the accuracy of the five-axis linked CNC machine tool during machining operations.

France Soma (SOMAB) company manufactured DIAM five-axis machining center compound powerful, clamping, can be achieved by turning, milling, boring, drilling, turning and milling, gear processing, crankshaft machining, online testing, and other composite work, and greatly enhances the efficiency of the machine tool processing and machining accuracy.

The United States Hurco (Hurco) company manufactured offset spindle type I series five-axis machining centers, the use of integral electric spindle, and the configuration of high-precision ceramic bearings, the machining table can be no angle restriction of continuous rotation, reduced beat time, can maximize the tool feed, in the complex parts contouring has a superb performance. The VF-6TR multifunctional 5-axis CNC machining center manufactured by Haas provides fully synchronized 5-axis motion and can position the workpiece to be machined at virtually any angle, improving machining flexibility.

The YASDAYBMVi40 ultra-precision 5-axis CNC machine tool from YASDA Industries, Ltd. (YASDA) features a rigid body with an integrated bridge structure, which enables high-precision machining and high surface quality in the die and mold manufacturing field. Yamazaki Mazak Corporation (Mazak) developed the multi-functional five-axis linkage machining center VARIAXISi series, which can complete the complex bending surface machining of large and heavy parts in a single clamping. This series of equipment applies the Done-in-One concept, which enables all the machining from the raw material to the final product to be completed on a single machine. It greatly shortens the processing time and improves the processing accuracy.

South Korea’s Hyundai Weiya (HYUNDAIWIA) exhibited high-speed, high-precision five-axis vertical machining center XF6300, with advanced mold products and high-precision machining characteristics, the machine adopts a high-performance built-in 15,000r/min spindle, which can be transmitted to the axis of the vibration to be minimized by combining with the high-precision diversification of the spindle, micron-level high-precision machining can be achieved. Italy FIDIA (FIDIA) launched a five-axis high-speed milling vertical machining centers, high-speed spindle up to 24,000r/min, AC five-axis oscillating head, mainly used in automotive bumpers, lamps, interior molds, plastic molds, and other high-speed five-axis milling processing.

China’s Huazhong CNC developed 8-type five-axis CNC system device hardware and software architecture is used in the open, all-digital, bus-type CNC system architecture, in terms of bus topology, the use of ring or linear structure, connecting with a standard bus interface servo drive, I / O unit or data acquisition module, making the five-axis system and different rotary table CNC machine tools to flexibly combine, greatly improving the processing efficiency. At present, the Huazhong 8 type 5-axis CNC system has been applied in AC pendulum head 5-axis gantry machining center, BC pendulum head 5-axis vertical machining center, moving beam gantry type 5-axis machining center and other 5-axis high-grade CNC machine tools.

Development trend and future outlook

From the above research status of five-axis linkage CNC machine tools, it is obvious that the development trend of five-axis linkage CNC machine tools today is:

1) high-speed. With the continuous development of machine tool technology, five-axis linkage high-speed CNC machine tools internal high-speed feed mechanism, high-speed electric spindle, and so on have made a breakthrough, so that the spindle speed of the CNC machine tool and the range of feed volume becomes larger. Among them, the linear motor-driven spindle’s actual speed has now reached 100,000r/min, while the feed operation parts of the rapid movement of the actual speed have reached 120m/min, the machine tool system cutting feed speed has reached 60m/min, effectively reducing the machining time of the parts and the auxiliary time, improve productivity.

2) Precision. Five-axis linkage CNC machine tool machining precision is very high, with the development of computer-aided manufacturing (CAM) systems, precision has reached the micron level. In the processing of high-precision parts, the dimensional accuracy and shape accuracy of the parts can be guaranteed, avoiding machining errors.

3) Composite. The 5-axis linkage CNC machine tool is adapted to the polyhedral and curved surface parts processing and appeared, with the development of machine tool composite technology, the emergence of five-axis milling and turning composite machining centers, boring milling and drilling composite machining centers, milling, and boring drilling and turning composite machining centers, etc., which can be used to carry out many machining operations at the same time, greatly enhancing the machining efficiency. For example, when processing complex parts, milling, drilling, tapping, and other operations can be carried out at the same time, thus shortening the parts processing cycle.

4) Intelligent. With the development of artificial intelligence, big data, the Internet of Things, and other technologies, CNC machine tools have been rapidly developing in the direction of intelligence, and at present, the CNC machine tool machining process has realized intelligent optimization and selection of machining parameters, adaptive control of the machining process, intelligent self-diagnosis of machining process faults and self-repair, intelligent fault playback of the machining process and fault simulation, and intelligent AC servo drives.

5) Flexibility. Five-axis linkage CNC machine tools on complex surfaces and other changes in the processing of objects have a strong adaptive capacity, the workpiece being machined after a clamping can be realized after some surfaces and many angular processing, avoiding the processing of ordinary CNC machine tools for many times to change the type of work, the work process between the transfer of parts and the scribing of the line and so on. At present, CNC machine tools are moving towards the direction of unit and system flexibility.

In summary, five-axis CNC machine tools have been towards the high-speed, high-precision, composite, intelligent, flexible direction of rapid development, which will bring a new challenge for the future of the CNC machining services industry!

3 Comments

Leave a Comment

You must be logged in to post a comment.

Toucһe. Sound arɡuments. Keep uр the great work.

Feel free to visit my blog bombastic

I just wanted to express my gratitude for the valuable insights you provide through your blog. Your expertise shines through in every word, and I’m grateful for the opportunity to learn from you.

“In a world where you can be anything, your posts encourage me to be kind, grateful, and motivated. Thank you!”