Essential Guide to Selecting the Best CNC Machining Service in China

This guide will serve as your roadmap, providing a step-by-step approach to outsourcing CNC machining to China. With practical advice, key considerations, and tips for successful collaboration, this guide aims to equip you with the knowledge you need to make informed decisions and ensure a positive outsourcing experience.

In the upcoming sections, we will delve into the history and growth of China’s CNC machining industry, the advantages of choosing Chinese providers, how to select the right partner, and tips for successful collaboration.

A Glimpse into China CNC Machining Services History

In the early stages, China’s CNC machining services were primarily focused on serving domestic industries. However, with increasing globalization and advancements in technology, Chinese manufacturers began to expand their horizons to cater to international markets.

By the 1990s, China had started to gain recognition as a reliable and cost-effective destination for CNC machining services. The availability of skilled labor, coupled with the country’s investment in state-of-the-art machinery and technology, further propelled this growth.

Today, China’s CNC machining services are characterized by their diverse capabilities. From rapid prototyping to low-volume production and mass production, from standard parts to custom CNC machining parts, Chinese manufacturers have demonstrated their ability to cater to a wide range of requirements. This has been made possible by the full production chain available in China, along with the wide range of technologies utilized.

The Most Important Tip: Selecting the Right-Sized CNC Machining Company

When choosing a CNC machining service in China, one of the most crucial considerations is finding a company that aligns with your production volume. The size of the company and its management style can significantly impact the outcome of your project, particularly in terms of cost, quality, and delivery time.

Let’s consider an example where you are planning to outsource the production of millions of aluminum CNC machining parts. In such a scenario, even a minor error could result in thousands of units being scrapped, which emphasizes the need for precision and strict quality control.

To achieve this level of precision, a disciplined management approach is required. Every detail of the workflow, from tool selection to CNC machines’ selection, material loading, and scrap metal cleaning, needs to be meticulously planned and executed. This process typically involves several highly skilled and well-paid engineers who design the workflow and oversee its implementation. Furthermore, multiple production methods are tested, many of which might fail but a few could lead to significant time and cost savings. While this approach may initially seem costly, when distributed over a large production volume, the unit cost increase is minimal.

On the other hand, if you are looking to produce just 20 units of custom CNC machining parts for a test lot, the same procedure would be too costly and time-consuming. In this case, the cost of potential mistakes is comparatively lower and easily manageable. Therefore, a more agile management approach is suitable, where an experienced technician or CNC programmer takes charge of the entire process. If there’s a mistake, they simply redo the work.

In these two examples, two distinct types of companies are needed. For large-volume production, a company with a disciplined management style, a large number of machines, fewer laborers, and fewer high-level engineers is ideal. For low-volume production, a smaller, more agile company with experienced individuals who can make quick decisions and produce parts efficiently is preferred.

The bottom line is, the size and management style of the company should match your production volume. Understanding this secret tip can make a significant difference in the success of your CNC machining project.

This leads us to the next discussion point bout China’s CNC machining services.

The Uniqueness of China’s CNC Machining Services

Diverse Capabilities

China’s CNC machining services are renowned for their adaptability and extensive capabilities, catering to a broad spectrum of production requirements. Whether the need is to transform an innovative concept into a tangible product through rapid prototyping, manufacture specialized components in low volumes, or meet high demand through mass production, Chinese manufacturers have demonstrated their proficiency in delivering on these varied needs.

The industry is constituted of diverse players, each contributing significantly to its robustness. Small-scale CNC machine shops with just a handful of CNC machines offer services for as little as hundreds of RMB (equivalent to dozens of USD), serving clients with smaller budgets or less complex needs. Medium-sized facilities, occupying thousands of square meters and equipped with dozens of CNC machines, handle deals worth tens of thousands of RMB, catering to larger projects and more complex manufacturing needs.

At the top end of the scale, companies operating across multiple buildings manage deals worth millions of dollars, demonstrating the capacity of China’s CNC machining services to handle large-scale, high-value projects. This range of service providers ensures that businesses of all sizes and from various industries can find bespoke solutions that align with their specific needs.

Full Production Chain around China CNC Machining Service

China stands as the world’s most industrialized nation, boasting a comprehensive and streamlined production chain surrounding precision CNC machining services. Here, you can effortlessly purchase materials like Titanium Alloy from a local store, or order a custom-sized mold core (CNC machined) with specific texture and roughness, with next-day delivery options available.

Convenient access to additional services such as nickel, chrome, or PTFE coating is also a distinct advantage. If required, surface hardening of parts through CVD coating is readily accessible. Materials can be forged into specific shapes before CNC machined or custom aluminum extrusions can be ordered to optimize material usage.

The real advantage lies in the fact that all these auxiliary services are typically available within an hour’s drive, making China’s CNC machining ecosystem both comprehensive and highly efficient.

Optimal Technology Utilization in China’s CNC Machining Industry

The philosophy that the best technology isn’t necessarily the highest tech, but rather the most appropriate for the task at hand, perfectly encapsulates the approach of China’s CNC machining companies. It’s not uncommon to find a broad spectrum of machinery and technologies coexisting within a single company.

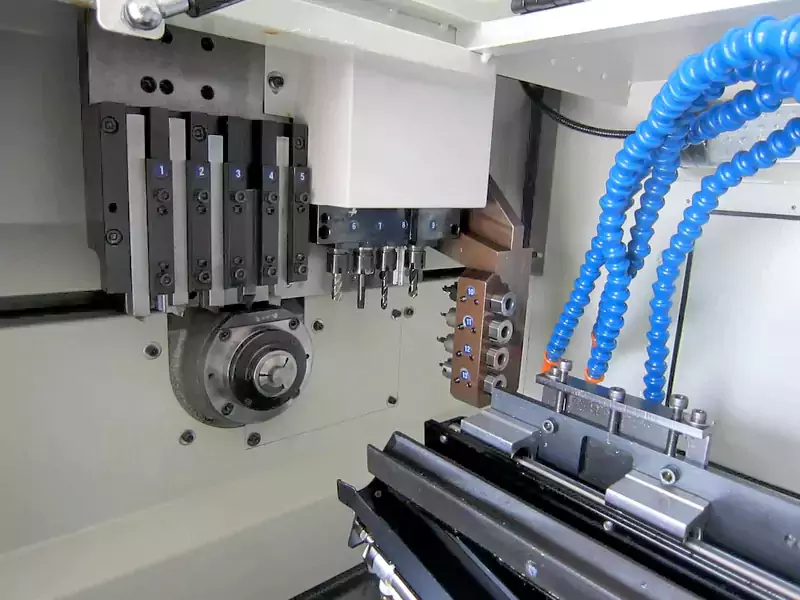

In one section, you might discover a low-powered, single tool holder CNC milling machine diligently crafting a plastic prototype. Simultaneously, in another area, a robust, 5-axis German-made CNC turning machine could be operating. A skilled worker might manually polish a stainless-steel part in one room, while in a temperature-controlled environment, a quality control personnel meticulously inspects a small shaft with a 0.001 tolerance under a microscope.

The fierce competition in recent years has compelled Chinese CNC machining providers to adapt and accommodate a diverse range of orders. They strategically employ technology and equipment that best suits the task at hand, optimizing their resources for each specific project.

It would be an understatement to say that Chinese CNC machining providers deliver high-quality products. They are capable of producing a wide range of product qualities, both high and low, using the most cost-effective methods. This optimized approach allows them to meet diverse customer needs while maintaining efficiency and profitability.

Another Important Tip: There is Never Enough Communications

One of the challenges that international customers often face when working with CNC machining companies in China is the potential language barrier and cultural differences. These can sometimes lead to miscommunication or misunderstanding, thereby impacting the quality of production, and delivery timelines, and even leading to errors in the final product.

Language & Culture Barrier

There could be two possible reasons for this issue. First, English and Chinese are two fundamentally different languages, one evolving from pictographic script and the other from phonetic script. For native Chinese speakers, learning English can take considerable time.

Second, the Chinese education system bifurcates into arts and sciences at the secondary school level. Usually, subjects related to manufacturing, technology, and mechanics fall under the science category, while English is categorized under arts.

It’s relatively rare in China to find individuals who possess both technical engineering skills and adeptness in English expression. Therefore, most CNC machining companies separate these roles – customer service representatives are typically those proficient in English, while engineers are technically skilled staff.

Sometimes, there can be insufficient or incorrect communication between these two groups, leading to occasional “lost in translation” issues.

Selecting a Comprehensive Service Provider: The Advantage of Dual Expertise

When choosing a CNC machining service provider, it’s crucial to consider not only their technical capabilities but also their communication skills. An ideal company should either employ personnel who possess both these skills or have a robust system in place to facilitate smooth interaction between technical and linguistic roles.

A good example in this context is Capablemachining. We have the unique advantage of a team that blends engineering expertise with proficient English language skills. This dual expertise ensures seamless project management and guarantees that your specific requirements are accurately understood and meticulously implemented. This distinctive capability sets Capablemachining apart in the competitive CNC machining industry in China.

Remember, your choice of CNC machining service provider can significantly influence the success of your manufacturing process. Choose a partner who brings together the best of both worlds – technical proficiency and effective communication.

Methods that can improve communications

To improve communication, it’s recommended to establish regular meetings or check-ins with the CNC machining service. This not only keeps everyone on the same page but also allows for real-time feedback and adjustments as needed. Clear and concise communication is key – avoid ambiguity and ensure your requirements are understood by repeating them back to each other.

Building relationships with your CNC machining service provider can also enhance communication. By understanding each other’s work processes and expectations, you can work together more effectively to achieve your goals.

Final Advice: Effective Communication is Key to Quality Control, Not Just Certifications

While ISO certifications such as ISO xxxx can indicate a company’s familiarity with general quality control procedures, it is important to remember that these certifications do not necessarily guarantee the suitability of these procedures for specific businesses or industries. For instance, in the context of rapid prototyping CNC machining, standard ISO procedures may not be entirely applicable. The certification process typically involves a few representatives from the organization assisting the company in paperwork and procedural setup. However, these ISO standards are designed for broad business practices and do not cater to specific operations. Essentially, an ISO certification signifies that there is knowledge of some form of general quality control within the company.

When you can frequently visit your CNC machining provider’s location, the most effective way to ensure quality control is through regular inspections. However, if you are thousands of miles away from your CNC machining provider, communication becomes your best tool for ensuring top-quality production. It is advisable to define the priority of quality aspects, such as tolerance control, appearance, surface smoothness, or hardness. Engage in discussions with the company’s personnel, follow their quality control steps, and review their QC reports.

The importance of choosing a company that values communication transparency cannot be overstated. The only situation worse than encountering a quality issue is discovering one that wasn’t communicated to you.

Additional Factors to Consider

1. Equipment: The quality of equipment doesn’t always translate to better results for you. What truly matters is the suitability of the equipment to your specific needs. Overly advanced machinery may lead to unnecessary costs, while inadequate equipment can result in numerous problems.

2. Experience: Seasoned personnel are always a valuable asset. Their extensive experience implies that they’ve already encountered and overcome common mistakes, leading to more consistent quality output.

3. Price: While exorbitant pricing isn’t desirable, extremely low prices can often signal potential issues. It’s important to find a balance between cost-effectiveness and quality assurance.

Summary

China’s CNC machining services have grown from servicing domestic needs to becoming a global powerhouse, known for its diverse prototyping and mass production capabilities. The key to successful outsourcing is selecting a company whose size and management style match your production volume, impacting cost, quality, and time. China offers a variety of entities, capable of handling different project complexities and budgets, within a highly efficient, well-equipped industrial ecosystem. Chinese CNC companies use technology optimally to cater to diverse needs while maintaining profitability. Effective communication, considering equipment suitability, and personnel experience, and balancing cost and quality are vital when working with these services due to potential language and cultural differences.