Finding the Best CNC Machining Service Provider in China: Tips and Tricks

CNC machining services have become increasingly popular in recent years due to their precision, speed, and ability to produce complex parts with a high level of accuracy. China has become a global leader in the industry, with a large number of companies offering services that cater to a broad range of needs. However, choosing the right CNC machining services in China can be challenging due to the sheer number of options available. In this article, we’ll provide you with a comprehensive guide on how to choose the right CNC machining services in China.

Is Outsourcing CNC Machining Cost-Effective for Your Business?

Before making any decisions, it’s essential to weigh the benefits and drawbacks. Working with an external CNC machining company can provide numerous benefits for businesses that require a precision manufacturing process. Here are some reasons why you might consider outsourcing your precision CNC machining needs to an external shop:

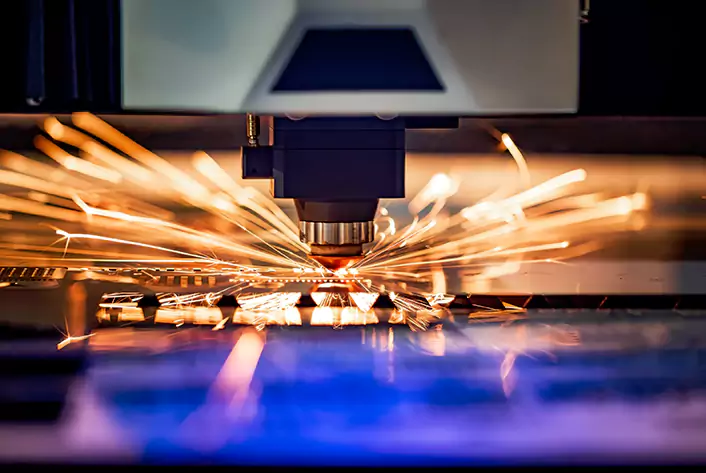

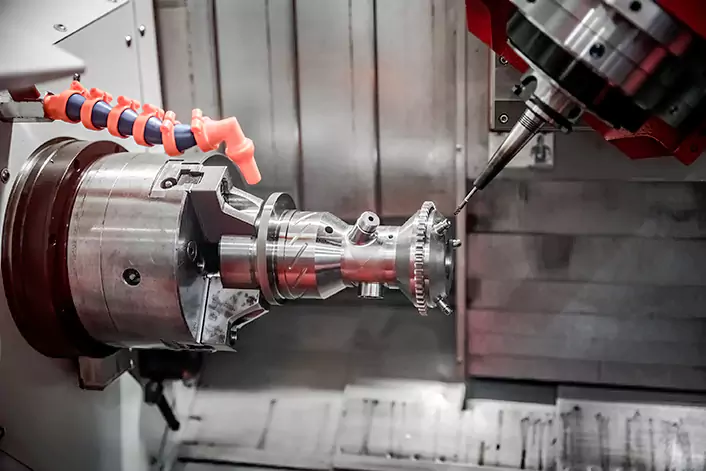

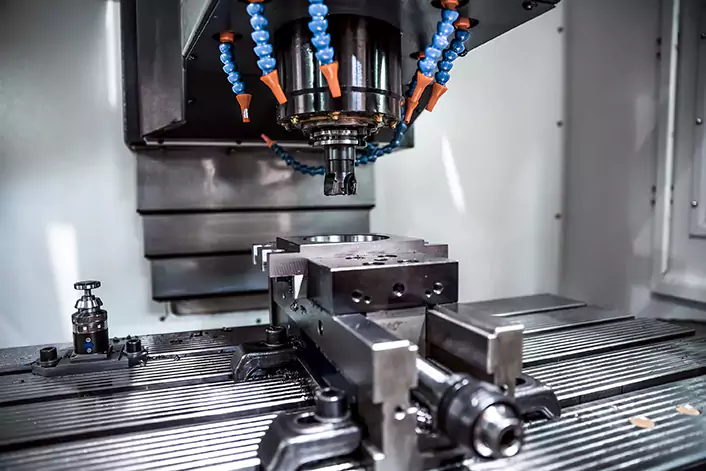

1. Access to advanced technology and equipment

CNC machine shops invest heavily in advanced technology and equipment to provide their clients with accurate, efficient, and custom machining services. By partnering with a professional CNC machining company, you can take advantage of the latest technology and equipment without the need for additional investments.

2. Expertise and experience

CNC machine shops have teams of experienced engineers and technicians who are skilled in designing and manufacturing high-precision parts. These professionals have the expertise and experience necessary to ensure that your production parts are made to the highest standards and specifications.

3. Cost savings

Outsourcing CNC machining services can help businesses save money by reducing the need for in-house equipment and personnel. Additionally, the CNC machine shop can provide economies of scale that can help reduce the overall cost of production.

4. Faster turnaround times

The CNC machine shop typically has a large production capacity and can deliver finished products faster than businesses with limited in-house capacity. This can be particularly beneficial for businesses with tight deadlines or urgent orders.

5. Flexibility

Outsourcing CNC machining services allows businesses to scale production up or down as needed without the need for additional investments in equipment or personnel. This can be particularly beneficial for businesses with fluctuating demand or short-term projects.

Why Should You Outsource Your CNC Machining Projects to China?

China’s CNC machining services have always been sought after by the world, providing high-quality machining services for global customers. Next, we will look at the latest market trends, techniques, improvements, benefits, and how Chinese CNC machining services compare to other countries.

1. Market Trends

The CNC machining and rapid prototyping industry in China has experienced significant growth in recent years, with a number of trends emerging that have helped to shape the market. According to recent reports, the CNC machining market in China is expected to continue growing at a steady rate in the coming years, driven by factors such as increasing demand for precision manufacturing services, rising investment in the manufacturing sector, and a growing focus on innovation and technological advancement.

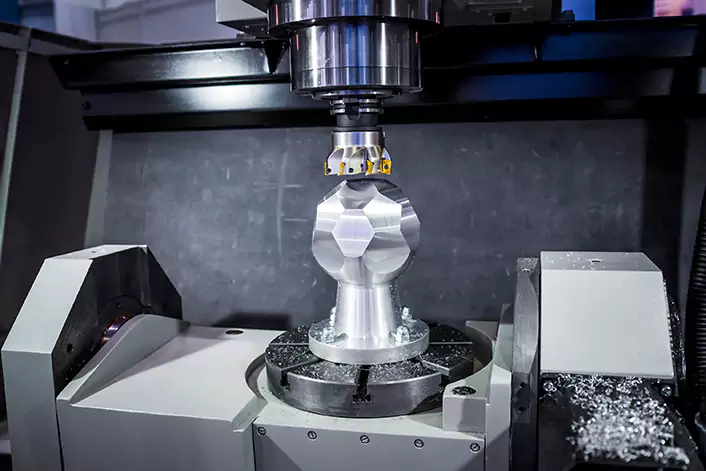

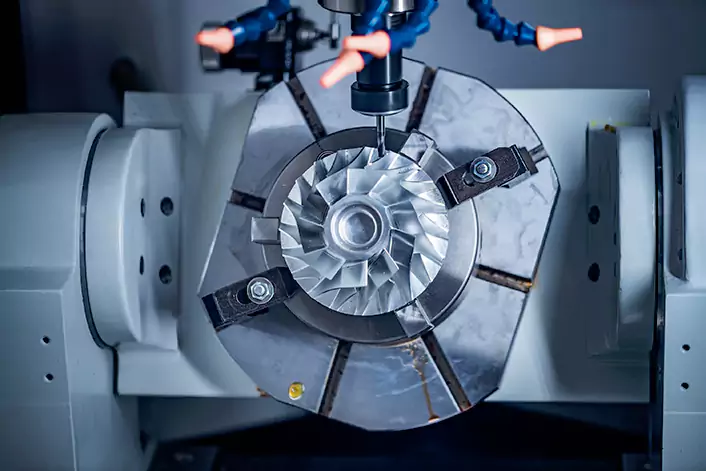

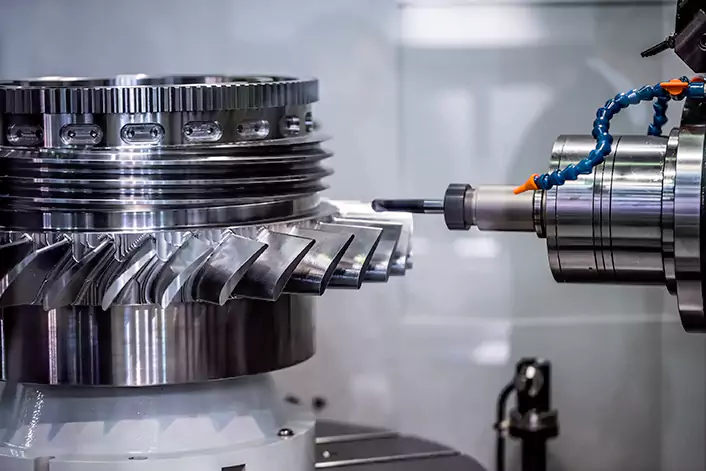

One of the key trends in the Chinese CNC machining market is the growing adoption of advanced technologies such as 5-axis machining, which allows for greater precision and accuracy in the production of complex parts and components. This has helped to cement China’s position as a leading provider of precision CNC machining services, particularly in the aerospace, automotive, and medical industries.

2. Techniques

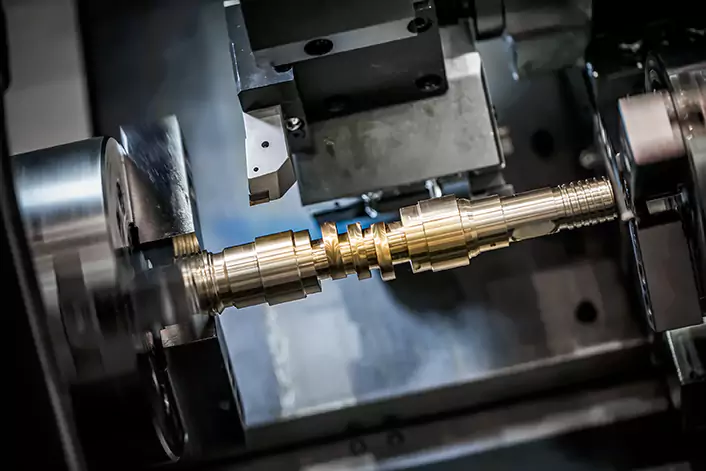

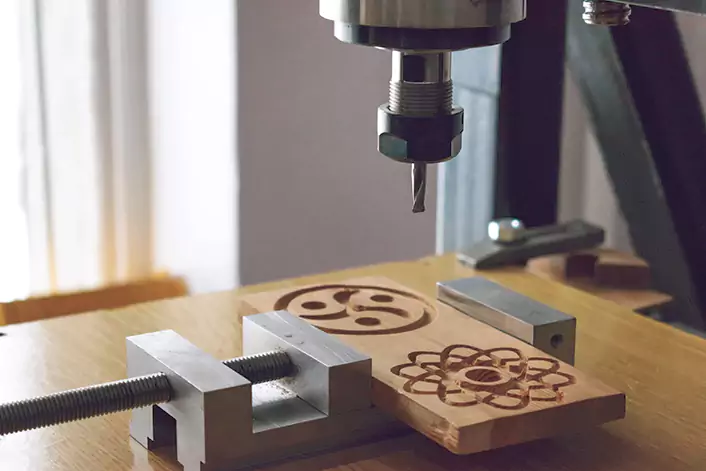

China is at the forefront of the precision machining industry, and its advanced machining technologies are leading the way in precision manufacturing. CNC machining is a process that uses computer numerical control to automate machine tools, and it allows for high precision and accuracy in manufacturing.

Precision techniques used in CNC machining include CAD/CAM (computer-aided design and computer-aided manufacturing), which allows for the creation of 3D models that can be used to generate CNC tool paths. Other precision techniques include 3D printing, which allows for the creation of complex geometries with high accuracy and consistency.

Programming strategies are another important aspect of CNC machining. These strategies can be used to improve efficiency, reduce cycle times, and increase productivity. Some of the programming strategies used in CNC machining include optimizing tool paths, reducing tool changes, and using multiple operations simultaneously.

3. Improvements

China is constantly improving its CNC machining technology to remain at the forefront of the industry. The latest CNC machining tools, such as 5-axis machines, are now available in China, which allows for the creation of complex geometries with higher precision and accuracy.

Advancements in materials are also improving custom CNC machining in China. New materials, such as high-performance alloys and composites, are being developed, and these materials require advanced machining techniques to manufacture. In addition, standardization of the CNC machining process is also being implemented in China, which allows for greater consistency and quality control.

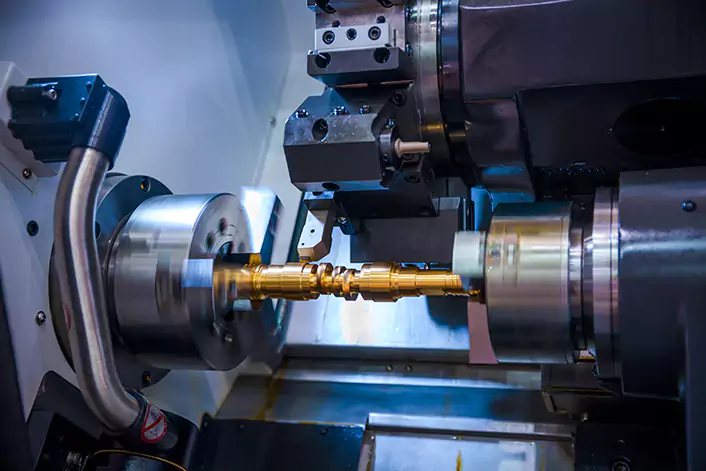

Automation is another area where China is making great strides in custom CNC machining. The introduction of robotics in CNC machining is becoming more common, and it allows for more efficient and consistent production. Robotic systems can be programmed to perform repetitive tasks, freeing up workers to focus on other aspects of production.

4. Benefits of China CNC Machining

There are many benefits to using a Chinese CNC machining service. One of the primary benefits is cost-effective production. CNC machining can produce high-quality machined parts at a lower cost than traditional manufacturing methods, which allows for greater competitiveness in the global market.

Another benefit of CNC machining is its high accuracy and precision. CNC machines can produce parts with tolerances as tight as a few microns, which allows for the creation of complex geometries with high precision and consistency.

Fast turnaround times are another advantage of CNC machining in China. CNC machines can produce parts quickly and efficiently, which allows for faster delivery times and shorter lead times. This is particularly important in industries where speed is critical, such as aerospace and automotive manufacturing.

In summary, China’s CNC machining techniques are advanced, and its precision and programming strategies are improving efficiency and productivity. With the latest CNC machining tools, advancements in materials and standardization, and the introduction of robotics, China is at the forefront of the industry. The cost-effective production, high accuracy and precision, and fast turnaround times are just a few of the benefits of CNC machining in China.

5. Comparison with Other Countries in the Industry

While China is undoubtedly a major player in the CNC machining industry, it is not the only country that has made significant strides in this area. Other countries such as Japan, Germany, and the United States have also developed strong CNC machining sectors, with each country offering its own unique strengths and advantages.

For example, Japan is renowned for its precision manufacturing capabilities, particularly in the area of high-speed machining. Germany is known for its focus on quality and reliability, while the United States has a strong tradition of innovation and technological advancement.

Despite this competition, China’s CNC machining industry remains a force to be reckoned with, thanks to the country’s combination of low-cost manufacturing, skilled workforce, cutting-edge technology and strong domestic supply chains. As the market continues to evolve and new technologies emerge, it is likely that China will remain at the forefront of the global CNC machining and manufacturing industry for many years to come.

What to Consider When Choosing a CNC Machine Shop in China?

1. Look for experience and expertise

One of the most important factors to consider when choosing a CNC machine shop in China is their level of experience and expertise. Look for companies that have been in business for several years and have a proven track record of delivering high-quality services. It’s also essential to consider the level of expertise of their staff, including their engineers and technicians. Experienced professionals are more likely to produce accurate CNC machined parts with a faster turnaround time than those who are new to the industry.

2. Check their equipment and facilities

Another crucial factor to consider when selecting a CNC machine shop in China is the quality of its equipment and facilities. High-quality equipment and advanced technology are necessary to produce accurate and high-precision parts. Therefore, look for companies that have invested in modern and well-maintained machines, as well as facilities that are clean, organized, and efficient.

3. Consider their capacity and scalability

When choosing a CNC machine shop in China, it’s crucial to consider their capacity and scalability. This is especially important if you have a large project or need to produce parts on a regular basis. Look for companies that have the capacity to handle your project and can scale up or down depending on your needs. This will help ensure that your project is completed on time and within budget.

4. Evaluate their quality control processes

Quality control is an essential aspect of CNC machining services. A reliable and reputable service provider should have a robust quality control process in place to ensure that all parts are manufactured to the highest standards. Ask the company about its quality control processes, including the tools and methods they use to verify the accuracy and precision of its parts.

5. Look for a company that offers customization

If you need customized parts, it’s essential to choose a CNC machining service provider in China that offers customization services. This will ensure that your parts are tailored to your specific needs and requirements. Look for companies that have experience in producing customized parts and can work closely with you to ensure that your project is a success.

6. Consider their pricing

Pricing is an important factor to consider when choosing a CNC machining service provider in China. While you don’t want to compromise on quality, it’s important to find a company that offers competitive pricing for its services. Look for companies that offer transparent pricing and provide detailed quotes that include all costs associated with your project.

7. Look for a company that offers excellent customer service

Lastly, it’s essential to choose a CNC machining service provider in China that offers excellent customer service. Look for companies that are responsive to your inquiries, communicate regularly throughout the project, and are willing to go the extra mile to ensure that your project is a success. Good customer service is a sign of a company that is committed to delivering high-quality services and building long-term relationships with their clients.

Why Should You Choose Capable Machining for Your CNC Machining Project?

Capable Machining is a reputable company that specializes in providing high-quality CNC machining services. There are several reasons why you might consider choosing Capable Machining for your CNC machining projects.

1. Experienced and Skilled Machinists

Capable Machining has a team of experienced and skilled machinists who are experts in CNC milling, injection molding, machining prototypes and more to manufacture custom machined parts. They have years of experience in the industry, which means they have the knowledge and expertise to produce high-quality parts and components that meet your exact specifications.

2. State-of-the-Art Technology

Capable Machining uses the latest technology and techniques to ensure that your parts are manufactured accurately and efficiently. They have state-of-the-art CNC milling machines and advanced software that allows them to produce complex parts with precision and accuracy.

3. Quality Control

Capable Machining has a rigorous quality control process in place to ensure that each part meets the highest standards of quality and reliability. This includes thorough inspections and testing of every part before it is shipped to the customer.

4. Customization

Capable Machining offers customization options to meet your unique needs. They can work with you to design and produce parts that are tailored to your specific requirements.

5. Competitive Pricing

Capable Machining offers competitive pricing for its CNC milling services. They strive to provide their customers with high-quality parts at an affordable price, ensuring that you get the best value for your money.

Overall, choosing Capable Machining for your CNC milling projects ensures that you receive high-quality parts that are manufactured efficiently and reliably, with a commitment to quality control, customization, and competitive pricing.

Conclusion

Choosing the right China CNC machining services can be challenging, but by considering the factors mentioned above, you can find a reliable and reputable company that meets your needs and requirements. Look for companies that have a proven track record of delivering high-quality services, invest in modern and well-maintained equipment, have the capacity to handle your project, and offer competitive pricing and excellent customer service. With the right CNC machining service provider in China, you can produce accurate and high-precision CNC machined parts with the desired shape.