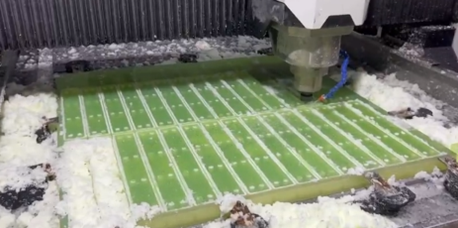

Most Common CNC material

Alu Alloy:

6061-T6

Most popular material for CNC. Easy to get from the market, easy to machine. No problem with anodizing. Low cost. Available in all sizes, and all common shapes. T6 standard for a heat treatment method. T6 is the most popular one, there are other heat treatment methods like T5, H1, and H2, but they are not as popular as T6, and mostly not as hard either.

Tensile Strength: 260 Mpa

Density: 2.7g/cm3

Cost: $$

6082-T6

Basically the same as 6061-T6. Slightly higher strength. Not as popular as 6061 alloy. Available in rods, and bars but rare in other shapes. No problem with anodizing.

Tensile Strength: 295 Mpa

Density: 2.7g/cm3

Cost: $$

7075-T6

Very high strength. This is the alloy that is used in the Japanese famous fighter Zero in WWII. The alloy’s strength is better than mild steel, almost the same as medium tensile carbon steel (for example, 1045), and only ⅓ of the weight. Less popular than the 6061 alloy because of the 7075 alloy’s higher price but still easy to find. Easy to machine. Anodizing color is brownish.

Tensile Strength: 525 Mpa

Density: 2.73g/cm3

Cost: $$$

Plastic:

POM / Acetal

One of the most popular engineering plastic used in CNC machining. Rigidity and hardness are higher than most plastics and easy to machine. It has a certain self-lubricating property, so it is often used in transmission parts such as gears and bearings.

Tensile Strength: about 60~78 Mpa

Density: 1.41g/com3

Cost:$$

ABS

ABS plastic is the most produced and most widely used polymer. The physical properties are relatively balanced, with good toughness, rigidity, and hardness. Basically does not absorb moisture. Good impact resistance. It has a wide range of applications such as joints, pipes, casings of various instruments, instrument panels, safety helmets, decorative materials, and so on.

Tensile Strength: about 28 Mpa

Density: 1.05~1.18g/cm3

Cost:$$

PA66

Rigidity, hardness, and strength are high. Low coefficient of friction, wear-resistant. Absorbs moisture, and changes in size due to moisture absorption in humid environments. Commonly used materials for CNC machining. Widely used in various mechanical parts and industrial structural parts.

Tensile Strength: about 85 Mpa

Density: 1.15g/cm3

Cost:$$

PA6

The strength is slightly inferior to PA66. It still has higher strength, stiffness, wear resistance and mechanical damping. Commonly used in mechanical parts and mechanical structural parts, especially sliding parts.

Tensile Strength: about 75 Mpa

Density: 1.14g/cm3

Cost:$$

Peek

Very expensive material. It has physical and chemical properties such as high-temperature resistance and chemical resistance. It is a kind of semi-crystalline polymer material and can be used as high-temperature resistant structural material and electrically insulating material.

It has high mechanical strength, self-lubricating, high-temperature resistance, impact resistance, flame retardant, acid and alkali resistance, hydrolysis resistance, wear resistance, fatigue resistance, radiation resistance, and good electrical properties.

Due to its excellent comprehensive properties, PEEK can replace traditional materials such as metals and ceramics in many special fields. It is mainly used in aerospace, the automotive industry, electrical and electronic and medical equipment, and other fields.

Tensile Strength: about 96.5 Mpa

Density: 1.35g/cm3

Cost:$$$$$$

PTFE

The most prominent feature: is extremely good chemical stability. Resistant to almost any substance, including sodium hydroxide, aqua regia, and hydrofluoric acid. It can be used continuously at high temperatures, and the PTFE coating on the non-stick pan takes advantage of this characteristic of PTFE. Very low coefficient of friction, excellent lubricating properties. Commonly used in container linings, bearings, sliding parts, valves, and other parts that require wear or corrosion resistance.

Tensile Strength: about 96.5 Mpa

Density: 2.2g/cm3

Cost:$$

Medium Carbon Steel:

AISI C1045

Most often used carbon steel in CNC machining. It is most often supplied in an annealed state, but also in a quenched and tempered (25~30HRC) state. Various shapes and sizes are readily available. The hardness can be increased to HRC40~45 by quenching and tempering. The anti-corrosion performance can be enhanced by surface treatment such as electroplating, powder spraying, and blackening. It is a low-cost material. Widely used in mechanical parts in almost all fields.

Tensile Strength: 570~700Mpa

Density: 7.8g/cm3

Cost:$

Cr12/DIN1.2080/Jis SKD1/Asm D3/Iso 210Cr12:

Cr12 is the Most often used mold steel in CNC machining. When 1045 steel is hardened over HRC45, it becomes brittle. If we need a higher hardness (or rigidity) part, Cr12 steel can be hardened over HRC60. In addition to CNC machining, Cr12 die steel is mainly used for cold die working parts (punch and die), cold extrusion die, etc., which require high wear resistance and less impact load. In most cases, Cr12 is supplied in the annealed state.

Tensile Strength: 470~1220Mpa

Density: 7.8g/cm3

Cost:$$

65Mn/ASTM 1566:

After quenching, it is rigid, elastic, and anti-fatigue. It is mostly used to make springs, spring sheets, shock-absorbing suspensions, kitchen knives, etc. that require both hardness and toughness. Workability is good before quenching. After quenching-tempering, the hardness can reach above HRC58.

Tensile Strength: 980Mpa

Density: 7.85g/cm3

Cost:$$

Stainless Steel: SUS303, 304, 316:

Stainless Steel: SUS303, 304, 316:

SUS303: Cr 18%~19%, Ni 8%~10%, Mn 2%, P 0.2%, C 0.15%, S 0.15%,Fe rest.

SUS304: Cr 17.5%~19.5%, Ni 8%~10.5%, Mn 2%, P 0.05%, C 0.15%, S 0.03%, Fe rest.

Stainless steel 303, and 304 both have excellent rust resistance. Under normal use, it is basically non-corrosion. 304 is more common than 303 and is used in a variety of tableware, knives, machine parts, containers, and more. 303 is used similarly to 304 but is more commonly used in mechanical parts. Both can be further hardened by a salt bath.

The difference between the two is that because the chemical composition of 303 contains slightly more sulfur, the machining is easier and the welding performance is poorer. For CNC machining, try to use 303 instead of 304 if possible.

Tensile Strength: 500~700Mpa

Density: 8g/cm3

Cost:$$$

SUS316:

Cr 16%~18%, Ni 10%~14%, Mo 2~3%, Mn 2%, P 0.045%, C 0.08%, S 0.03%, Si 1%, Fe rest.

Compared with 304 stainless steel, 316 stainless steel contains Mo, and the content of Ni is also higher. This makes the corrosion resistance of 316 better than that of 304. Therefore, it is more suitable for applications requiring better corrosion resistance, such as chemical containers, chemical equipment parts, medical equipment parts, equipment parts that are exposed to seawater or used in seawater, etc. 316 can be hardened by a salt bath. The material cost of 316 is higher than that of 304, and it is more difficult to CNC than 304.

Tensile Strength: 520Mpa

Density: 8g/cm3

Cost:$$$

SUS630/17-4 PH/UNS S17400:

Cr 15%~17%,Ni 3.0%~5.0%, Cu 3.0~5.0%, Si 1.0%,S 0.03%, P 0.04%, Mn 1.0%, C 0.07%, Nb,Ta 0.15%~0.45%,Fe rest.

The corrosion resistance of 630 stainless steel is similar to that of 304, and the CNC machining performance is also similar to that of 304. The most prominent feature is that different hardness and strength can be obtained by different heat treatment methods. A common heat treatment method is PH.

The treated material is 17-4 PH, and its strength and hardness are much higher than that of 304. Ductility is also very good, and so is impact resistance. It is suitable for various occasions that require both high strength and good corrosion resistance, such as offshore platforms, food processing equipment parts, turbine blades, etc. The price is higher than 304.

Tensile Strength: 930~1310Mpa

Density: 7.8g/cm3

Cost:$$$

SUS410, 440C:

Both SUS410 and 440C are martensitic stainless steels. It contains very little or no Ni, and its antirust performance depends on the level of Cr content. The antirust ability of 410 and 440C is not as good as SUS304, and the antirust ability is improved after polishing or grinding to form a bright surface.

The Cr content of 440C is higher than 410, and its anti-rust performance is better than that of 410, which can resist the corrosion of fresh water, water vapor, gasoline, and alcohol. The anti-rust ability of 410 is not as good as that of 440C. The author used SUS410 material to make a bright shaft. In a relatively humid environment (relative humidity above 80%), after more than 6 months, the surface of the shaft began to appear spot rust.

The most important feature of martensitic stainless steel is that it can be hardened by quenching and tempering processes like medium carbon steel. The hardness of SUS410 can reach HRC40 after quenching and tempering. SUS440C can reach HRC58 after quenching and tempering. SUS440C is often used to make cutting tools, etc., and its deformation during heat treatment is small, so it can be used to make precision guide rails.

Both materials are generally supplied in the annealed or tempered condition with low hardness.

SUS410

Cr 11.5~13.5%,S 0.03%,P 0.04%,Mn 1%,Si 1%,C,0.15%,Fe rest

SUS440C

Cr 16~18%,S 0.03%,P 0.04%,Mn 1%,Si 1%,C 0.95%~1.2%,Fe rest

Tensile Strength:

- 440C: 758~1960Mpa

- 410:755~1310Mpa

Density: 7.7g/cm3

Cost:$$$

Brass:

Brass is a copper-zinc alloy. Very easy to process, common models, are H59, H63 (copper content 59%, 63%), and so on. The price is also basically proportional to its copper content. It is mostly used to make sleeves, linings, pinions, and other small parts. Compared with steel materials, brass generally does not need surface treatment, and it is easier to process than steel, so the processing cost is lower.

Density:8.5~8.8g/cm3

Cost:$$$

Copper:

Easy for CNC to process. Most of them are used to make parts that require good electrical conductivity or thermal conductivity, such as electrodes, heat sinks, etc.

Density:8.96g/cm3

Cost:$$$$

Rubber, Polyamide:

Elastic materials such as NBR, EPDM, fluoro rubber, Polyurethane, etc, are mostly used for dampers or buffers. When Shore hardness is over 70, they can be CNC processed but with rather loose tolerances (+/-0.3mm).

CapableMachining believes that more and more complex materials can be processed by cnc machining, and the most important thing is to master the balance between economy, ease of processing, and whether the product meets the design requirements.