Overview of the global CNC machine tool industry

The status of CNC machine tools in modern manufacturing and its importance is self-evident. Its emergence breaks the limitations of traditional processing methods, enhances the technical level of the manufacturing industry, and promotes the process of industrial modernization, which is a fundamental, complex, and strategic material in modern industry.

With the continuous development and promotion of computer technology, CNC machine tool intelligence, and automation will continue to change people’s production methods, promoting the development of the manufacturing industry.

CNC machine tool characteristics

(1) technology-intensive, iterative accumulation.

CNC machine tools are a class of mechanical, electrical, hydraulic, control, hardware, software, information, network, sensing, and other multidisciplinary, multi-professional technology that is highly integrated in physical carrier products, highly technology-intensive, the need for long-term accumulation and iteration.

(2) Process segmentation, and variety.

Involving cutting (turning, milling, grinding, drilling, boring, broaching …), forming processing (forging, stamping, bending, shearing …), special processing (EDM, laser, ion beam, e-beam …), and other different categories and processes, the process is divided into more detailed, a wide range of product categories and models.

(3) Smaller market volume and lower profits.

The machine tool industry is often only a few percent of the size of the end-product industry it serves (such as automotive, construction machinery, aircraft manufacturing, etc.), which provides manufacturing tools for the class of products, product functionality and performance requirements are high but low profits.

(4) Labor-intensive, artisanal.

Due to the high requirements of motion accuracy and dynamic performance but small market size, it is difficult to carry out large-volume automated production, which requires many skilled workers with artisanal spirit.

(5) Capital alienation and hidden monopoly.

Although the machine tool industry, in general, is fully competitive in the world, in the field of high-grade CNC machine tools, the first entrant often establishes a strong competitive advantage in the market based on its technological accumulation, characterized by hidden monopoly, that is, the market mechanism in this field is a local failure.

Global advanced CNC machine tool manufacturer

According to the data and charts [18] given in “SEDI Consultant|2019 CNC Machine Tool Industry Data”, it can be known that the top 10 CNC machine tool manufacturers in the world ranked by scale in 2019 are all from the three countries of Japan, Germany, and the United States, with the following distribution:

(1) Japan: Yamazaki Mazak (No. 1), Amada (No. 5), Okuma (No. 6), Makino (No. 7);

(2) Germany: Trumpf (No. 2), DMG MORI (No. 3), GROB Group (No. 8), EMAG (No. 10);

(3) USA: Mag (No. 4), Haas (No. 9).

The total size of the global CNC machine tool industry continued to grow from 2017-2019, reaching $149.2 billion in 2019, but the growth rate declined for three consecutive years, from 9.5% in 2017 to 7.0% in 2018 and 3.9% in 2019. In addition, according to the forecast of Fortune Business Insight (FBI), the compound annual growth rate (CAGR) of the global machine tool industry from 2020 to 2027 is 4.5 percent.

From the point of view of industrial structure, broken down by product type, the CNC machine tool industry law in 2019 is as follows: CNC metal cutting machine tools $78.33 billion (accounting for 52.5%), CNC metal forming machine tools $42.07 billion (accounting for 28.2%), CNC special machining machine tools $26.56 billion (accounting for 17.8%), other $2.24 billion (accounting for 1.5%).

The global CNC machine tool industry is mainly concentrated in Asia, the European Union, and the Americas three major regions, including China, Japan, and Germany the main production of machine tools, and the regional structure of the distribution of Japan is 32.1%, China 31.5%, Germany 17.2%, the United States 6.3%, Italy 5.2%, South Korea, 4.2%, and other 3.5%.

CNC machine tool companies and technical conditions

Japan

Japan’s CNC machine tool industry and technology overview of Japan in the machine tool industry, especially in the field of high-grade CNC machine tools in the global leading position, the overall strength is located in the world’s first, with several famous machine tool companies and brands, such as Yamazaki Mazak, Tenda, Okuma, Mori Seiki, Jetta Kotaku, Makino, Mitsubishi Heavy Industries, Shadyshack and so on, Japan’s machine tool companies are numerous, leading technology. Listed below are some of the Japanese CNC machine tool companies and technical characteristics:

(1) NSK – bearing for its core products, and can be a full set of development and provide machine tool functional parts products (such as ball screws, linear guides, spindles, etc.), the industry scale ranks first in Japan, the world’s No. 3. can be produced Dmn value (bearing inner and outer rings average diameter Dm ×We can produce rolling bearings with Dmn values (average diameter of the inner and outer rings of the bearings, Dm) of up to 3,000,000 m-r/min and high-speed machine tool spindles (spindle speeds of up to 50,000 r/min). We serve automotive parts, precision machinery components, and electronic applications.

(2) Yamazaki Mazak – the main products are CNC lathes, composite turning and milling machining centers, vertical machining centers, horizontal machining centers, laser systems, FMS, CAD, CAM, CNC devices and production support software, etc., and the products are known for their High-speed, high-precision composite known.

(3) SNK – specializing in the production of large-scale gantry machining centers, lathes, special-purpose machines, etc., used in the manufacture of ship engines, airliners, main wings, and other large parts, such as its production of 5-axis gantry precision boring and milling machines are used in a large number of developed countries in the aerospace industry.

(4) JTEKT – the production of ultra-precision free-form diamond processing machine tools, precision to a high level (positioning accuracy of 30nm, surface roughness Ra = 1nm), can be used for ultra-precision turning and grinding of optical molds.

(5) SODICK – representative products are nanometer precision slow-feed EDM machine tools, but also introduced the world’s first “hybrid waterjet + wire cutting” machine tools.

(6) Amada – CNC punching, bending machine, shearing machine, laser cutting equipment, its molds, spare parts, and cutting products in this field in the global market No. 1 (70%) position.

(7) Okamoto – production of the world’s largest gantry surface grinding machine, variable hydrostatic guideway system, polishing large-size semiconductor components.

(8) OKUMA – Adheres to the independent development of everything from the core components of CNC machine tools (drives/encoders/motors/spindles, etc.) to the NC operating system and terminals.

(9) MAKINO – created many Japanese machine tools “No. 1”, vertical and horizontal machining centers, electrical machine tools (EDM), grinding machines, etc. as the main products, serving the mold, automotive, aviation, aerospace, and other industries. , aviation, aerospace, and other industries.

Germany

Germany is a global manufacturing power and power, especially in the field of machine tool industry has a unique advantage, after hundreds of years of precipitation, produced many globally renowned machine tool manufacturing enterprises. Some of the well-known enterprises and products are as follows:

(1) DMG Mori – with the three famous brands of Germany’s Delk, Maho, and Gitomer, and later united with Japan’s Mori Seiki, is the world’s leading and largest manufacturer of metal-cutting machine tools, including machine tools, services, and software solutions to provide a unique CELOS digital production management and control system.

(2) Trumpf – a global leader in technology and markets for industrial lasers, produces a wide range of lasers, laser processing machines, and CNC punching and bending machines.

(3) GROB – the main products are various machine tools, production systems or cutting line assembly units, fully automated assembly lines, specializing in engine parts turnkey projects, emphasizing process/technology/resources/cultural global integration.

(4) Emag – comprehensive and perfect technology, providing processing disk/shaft/gear/box type processing machine tools and production systems, laser welding machines. Inverted machine tools are unique.

(5) Schuler – in 1852, the production of metal processing machine tools, is a global leader in the metal forming industry, providing machine tools, production lines, automation technology, and related services, but also for aerospace and railroad solutions.

(6) Korber Schleifring – surface and profile grinding, internal and external cylindrical grinding, and tool grinding machine tools, widely used in aerospace, automotive and its components, heavy industry, and other fields (has provided more than 100,000 sets of grinding machines to the world, of which 600 sets in China). 0 units).

(7) Index – in 1914 began production of tower automatic lathes, 1975 production of multi-spindle automatic lathes. 1992 launched a new generation of modular components of the mill-turning complex center.

(8) Hermle – small and medium-sized five-axis precision machining experts in the field of 5-axis high-speed vertical machining centers, international leading technology, 5-axis machine tool market share of small and medium-sized molds and dies in the German domestic market share of the first, there have been more than 1.7 million sets of Hammer’s production of universal milling and machining centers used in the world. Used around the world.

USA

American CNC machine manufacturers lead in innovation and quality with cutting-edge facilities and technology. They produce diverse CNC machines for industries like aerospace and automotive, maintaining high production standards. Customization options set them apart globally, ensuring businesses find tailored solutions and cementing the USA’s leadership in CNC manufacturing.

(1) Mag – It has a strong reputation in the industry for its high-quality CNC machine tools, setting the standard for precision and reliability. Their commitment to producing state-of-the-art CNC machines makes them the first choice for businesses seeking superior performance and durability.

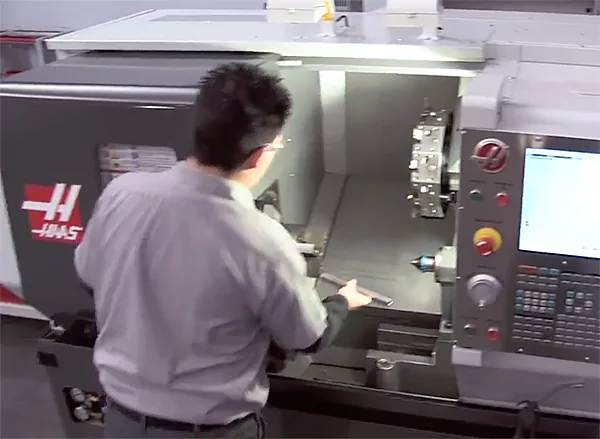

(2) Haas – It is one of the leading CNC machine tool manufacturers in the United States, known for its exceptional quality and precision. Their CNC lathe and CNC mill products are highly respected in the industry for their advanced technology and reliability.

(3) SYIL – When choosing the right CNC machine manufacturer, SYIL is a top contender for many reasons. One of the great benefits of choosing a SYIL CNC machine is its exceptional durability and precision, making it an ideal investment for any CNC machine shop.

(4) Fadal – With a rich heritage in the CNC machine tool manufacturing industry, we have a strong reputation for producing high-quality CNC machine tools that meet the needs of modern manufacturing.

(5) Hurco – Hurco CNC machines are known for their extensive customization options, allowing users to tailor their machines to specific manufacturing needs. Whether you need a CNC lathe or a CNC mill, Hurco offers a wide range of options to meet your requirements.

Other European countries

Switzerland, France, Italy, and other European countries in the process of industrialization have also produced many technological advantages and expertise in machine tool companies, especially in the segment-oriented high-precision and specialized machine tools and their overall solutions, with very strong competitiveness, these companies include:

(1) Switzerland Willemin-Ma-codelSA – products mainly vertical and gantry drilling and milling machining centers, the spindle Spindle speed up to 80,000r/min, trajectory accuracy of 2μm.

(2) Switzerland Tornos – the main production of high-precision micro/small parts processing machine tools, composite machine tools, etc., the use of ceramic spindle/dual spindle program, with active chip removal function.

(3) Switzerland GF Mikron – specializing in the production of large-scale gantry machining centers, lathes, special-purpose machines, etc., used in the manufacture of ship engines, airliners, main wings, and other large parts, such as 5-axis gantry precision boring and milling machine.

(4) Switzerland Starrag Heckert – milling/turning/boring/grinding and other processes for metal, composite materials, ceramics and other processing of high-precision machine tools leader in the aero-engine turbine/blade/structural parts processing/blade/structural parts processing is unique, in recent years also acquired the production of aviation structural parts processing with virtual axis CNC machine tools ECOSpeed/EcoForce and well-known German DST.

(5) Switzerland Liechti – blade processing solutions for the world’s leading, especially for aero-engines, gas turbines, blade discs, blades, and complex surfaces to provide high-speed CNC machine tools and special CAD/CAM software.

(6) Austria WFL – focusing on multi-functional complete machining center manufacturers, the development of mill-turn machining centers is widely used in aerospace, transportation, and other fields.

(7) Italy’s Ferrari – focusing on aero-engine, automotive field of complex curved surface parts processing machine tools, to provide automatic loading and unloading of 5-axis linkage blade machining centers, blade machining special CAM software.

(8) France ForestLine – focusing on aerospace large-scale structural parts for the processing of 5-axis gantry-type machining centers and composite components laying wire, laying tape machine tools.

Of course, the final use of lathes should be combined with our actual needs. After all, the cost of each operation of high-end lathes is very high. If the products they process are not products with high requirements, there is no need to use similar machine tools. What is suitable is the best.

We provide various machining services from the perspective of users, with the ultimate goal of creating value for customers.

“This is a great post about [Topic]! I enjoyed reading your perspectives on this subject. Your ideas are insightful and offer practical solutions. I look forward to more of your content.”