The Ultimate Guide to Plastic Welding: 10 Methods You Need to Know

Joining plastic parts is essential in many industries, and plastic welding is a versatile method that offers a reliable and cost-effective solution. In this article, we will explore the different methods of plastic welding, the benefits of plastic welding, and the applications of plastic welded parts.

What is plastic welding?

Plastic welding is a process that involves using heat and pressure to join two pieces of plastic together. The plastic is melted at the joint and then pressed together to create a strong bond. This process is similar to welding metal, but instead of melting the metal, the plastic is melted and fused together. It is a versatile technique that can be used on a wide range of thermoplastics and is commonly used in the automotive, construction, and manufacturing industries.

Methods

There are several plastic welding methods, and each method utilizes a different technique to join plastic together. The choice of welding technique depends on various factors, such as the type of plastic being used, the size and shape of the parts being welded, and the desired strength of the final product. Each technique has its advantages and disadvantages, and the selection of the appropriate technique is crucial to ensure a successful weld. Here are the most common methods of plastic welding:

1. Hot Gas Welding

Hot gas welding is a common method of plastic welding that involves heating the plastic with a hot air gun or torch until it melts. The hot air gun is directed at the joint between the two parts, melting the plastic and fusing the parts together. The melted plastic is then pressed together to create a strong bond.

Advantages of Hot Gas Welding

Allows for precise control over the temperature and speed of the welding process.

Can be used for both large and small welds

Relatively easy to perform

Fast and inexpensive compared to other plastic welding techniques.

Can be used for a variety of thermoplastics

Disadvantages of Hot Gas Welding

Requires specialized equipment

Can be time-consuming

Can produce fumes and odors

2. Hot Plate Welding

This method involves heating a hot plate and pressing it against the plastic to be welded. The hot plate is typically made of aluminum and is heated to a specific temperature depending on the type of plastic being welded. The two plastic parts are then placed on the hot plate until they reach the melting point. Once the plastic has melted, the hot plate is removed, and the two parts are pressed together under pressure until they cool and solidify, creating a strong bond.

Advantages of Hot Plate Welding

Ideal for large plastic parts

Strong welded joints

Short cycle time

Disadvantages of Hot Plate Welding

Not suitable for thin plastics

High maintenance

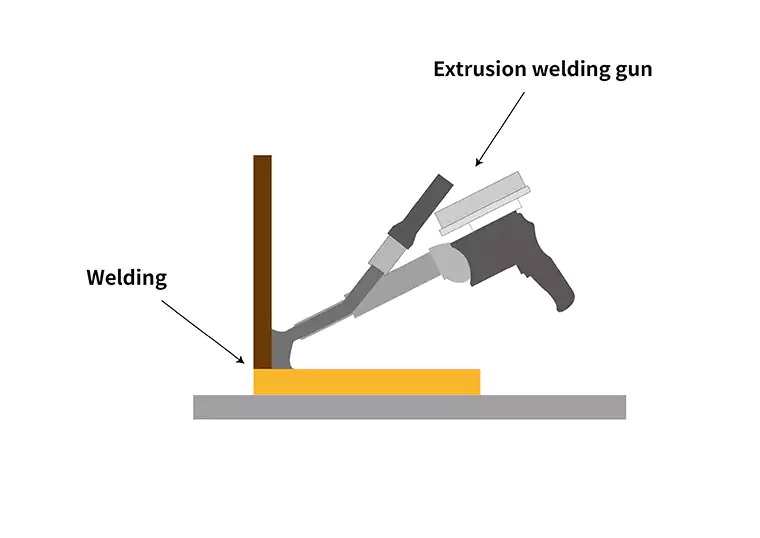

3. Extrusion Welding

Extrusion Welding is used for welding large plastic structures like pipes and tanks. It involves melting the plastic welding rods with a heated extrusion gun and then applying the melted plastic to the joint between two plastic parts. The extrusion gun has a nozzle that melts the welding rod and extrudes it onto the joint, creating a strong bond. Then welding rod is typically made of the same material as the plastic parts being welded, ensuring compatibility and a strong bond.

Advantages of Extrusion Welding

High-quality welds

Can join large areas

Can weld complex shapes

Can weld thick materials

No filler material required

Disadvantages of Extrusion Welding

Expensive equipment

Requires skilled operators

Limited to certain materials

Limited joint configurations

Requires proper safety precautions

Can produce fumes and odors during the welding process

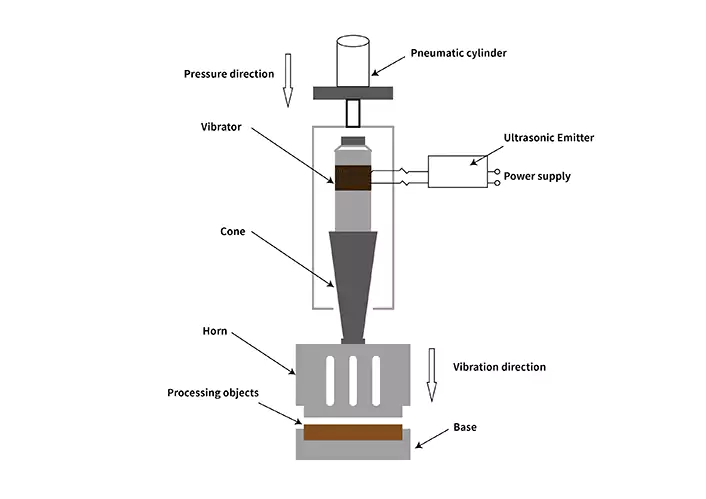

4. Ultrasonic Welding

Ultrasonic welding is a way to join things together using high-pitched sound waves. By vibrating the materials at the spot where they touch each other, they heat up and melt together. This method is commonly used for welding plastic. The electrical power is transformed into high-frequency signals that cause the materials to vibrate and generate heat, melting the plastic together.

Advantages of Ultrasonic Welding

Fast and precise

High-quality welded joint

No additional finishing processes

Suitable for heat-sensitive materials

Disadvantages of Ultrasonic Welding

Not suitable for some thermoplastics

Not ideal for thick materials

Only suitable for certain joint types

High lead time

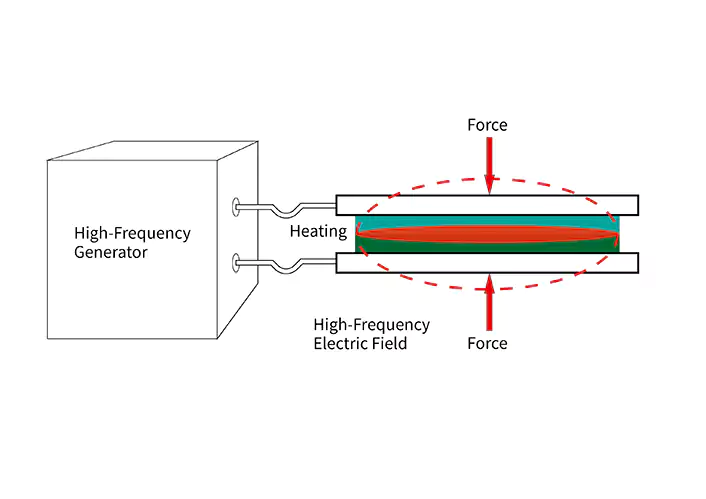

5. High-Frequency Welding

High-Frequency Welding also known as RF (Radio Frequency) Welding uses high-frequency

electromagnetic waves to generate heat and melt the plastic at the joint. The two plastic parts are held together under pressure created by 2 metal bars while a High-frequency electronic magnetic field is also created by the 2 metal bars. The dynamic electronic field cause the molecules in the thermoplastic to oscillate at an extremely high frequency, creating heat and melting the plastic. Once the plastic has melted, the High-frequency is removed, and the two parts are held together until they cool and solidify, creating a strong bond. The technology works better with high dielectric constant plastic, or more polarizable plastic, such as PVC.

Advantages of High-Frequency Welding

Fast process

High-quality welds

Can join a wide range of materials

No filler material required

Can weld complex shapes

Minimal distortion

Disadvantages of High-Frequency Welding

Expensive equipment

Limited to certain materials

Limited joint configurations

Requires proper safety precautions

Can produce fumes and odors during the welding process

Not suitable for thick materials

Can be affected by environmental factors such as humidity and temperature

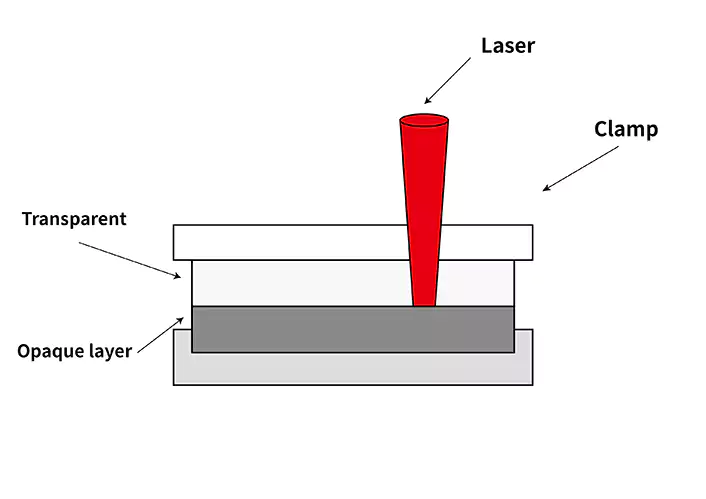

6. Laser Welding

Laser plastic welding is a method of bonding plastic using a laser beam. In laser welding 2 layers of plastic are held together, the top layer is transparent plastic (transmissive layer), and the bottom layer is a none transparent plastic (absorbing layer). The beam passes through the top layer of transparent plastic and creates heat when it reaches the lower layer. This heat melts the two layers together at their interface, creating a strong, fused bond. It’s different from traditional welding and is also known as through-transmission welding.

Laser welding is a highly precise and efficient welding method that is commonly used in the manufacturing of automobiles, aerospace components, medical devices, and electronics.

Advantages of Laser Welding

High precision

Fast process

Minimal distortion

Versatile

Clean process

Disadvantages of Laser Welding:

Expensive equipment

Requires proper safety precautions

Best suited for thin plastics

Requires clean materials

Limited joint configurations

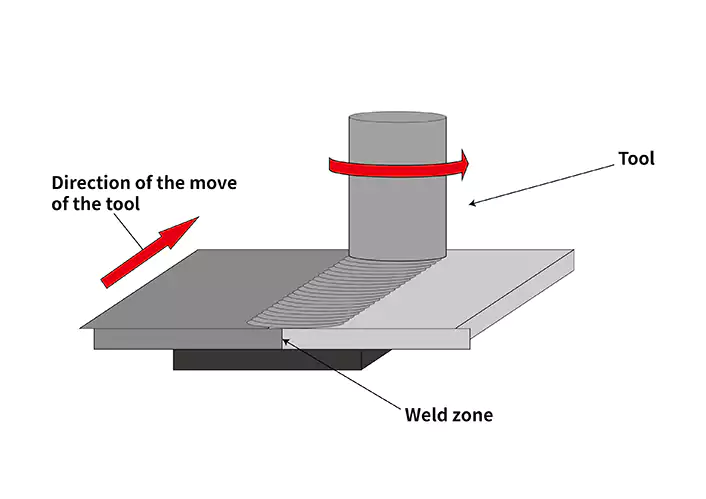

7. Friction Stir Welding

Friction Stir welding involves rubbing two pieces of plastic with a stir tool until they melt and fuse together. The two pieces of plastic are held together under pressure while a spinning tool creates friction between them, generating heat and melting the plastic. This method is commonly used for welding thermoplastics such as polyethylene, polypropylene, and nylon.

Advantages of Friction Welding

High-quality welds

No filler material required

Fast process

Environmentally friendly

Can join dissimilar materials

Disadvantages of Friction Welding

Limited to certain materials

Expensive equipment

Limited joint configurations

Requires proper safety precautions

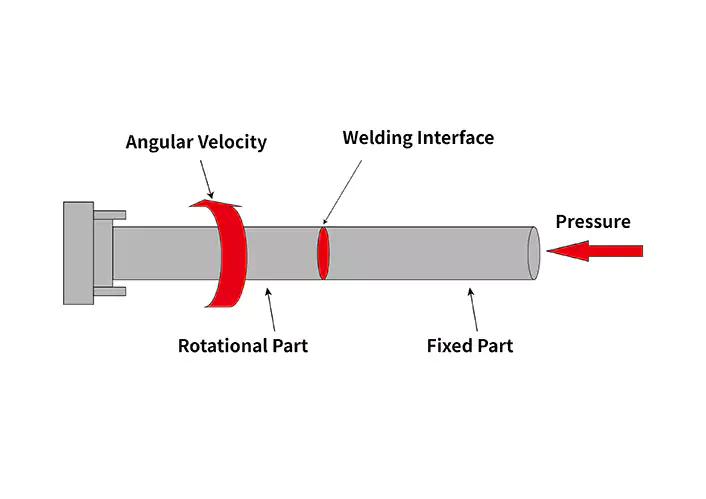

8. Friction Spin Welding

Spin welding is a process used to join two thermoplastic parts together. In this process, one part is held stationary while the other is rotated at high speed. The two parts are then pressed together, creating heat through friction. Once the materials reach a molten state, the rotation is stopped by a brake, and the parts are held together under pressure until they cool and solidify. This process creates a strong, hermetic seal between the two parts without the need for additional materials or adhesives. Spin welding is commonly used in the automotive, medical, and consumer goods industries for applications such as fuel tanks, filters, and medical devices.

Advantages of Spin Welding

High-quality welds

No filler material required

Fast process

Can join dissimilar materials

Good for small parts

Disadvantages of Spin Welding

Limited to certain materials

Limited joint configurations

Requires proper safety precautions

Not suitable for large parts

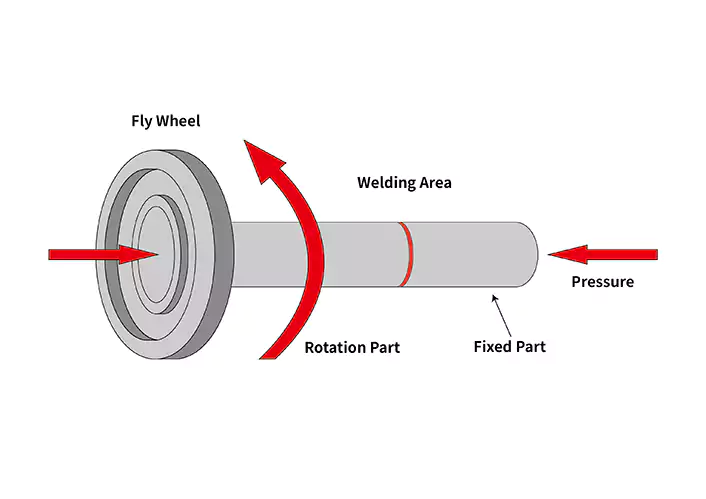

9. Inertia Friction Welding

Inertia friction welding is very much like spin welding. In this process, one part is held stationary while the other is rotated at high speed. The two parts are then pressed together, creating heat through friction. Inertia Welding differs from spin welding in the way how rotation is driving. In spin welding, the rotating part is driven by a motor and stops by a brake. In inertia welding, first, a wheel is spun to a certain speed. Then, it’s separated from the motor that makes it spin, and the two parts are pressed together with a force applied along the axis of rotation. As the wheel slows down, its energy creates heat between the parts, and this heat helps them stick together, finishing the welding process.

This process creates a strong, high-quality weld without the need for additional materials or adhesives. Inertia friction welding for plastic is commonly used in the automotive, aerospace, and consumer goods industries for applications such as air ducts, fuel tanks, and medical devices.

Advantages of Inertia Friction Welding

High-quality welds

No filler material required

Fast process

Can join dissimilar materials

Good for large parts

Advantages of Inertia Friction Welding

Expensive equipment

Limited to certain materials

Limited joint configurations

Requires proper safety precautions

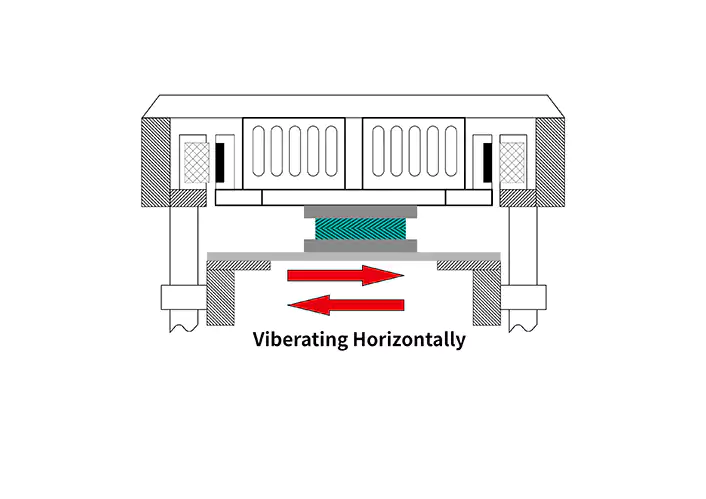

10. Vibration welding

Vibration welding uses friction to melt the plastic parts being welded. The two parts are held together under pressure and subjected to high-frequency vibration. The friction generated by the vibration causes the plastic to melt and fuse together. Vibration welding is commonly used on thermoplastics such as PP, PE, and PVC.

Advantages of Vibration welding

Fast and efficient

No need for surface preparation

Can produce a strong and durable joint

Can be used on parts of varying thicknesses and shape

Advantages of Vibration welding

Expensive equipment

Limited compatible materials

Benefits

It offers several benefits over other joining methods. Here are some of the benefits:

1. Strong and durable bond

Plastic welding creates a strong and durable bond between plastic parts that is resistant to vibration, impact, and temperature changes. This makes the welding suitable for applications where a strong and long-lasting bond is required.

2. Cost-effective

Plastic welding is a cost-effective method compared to other joining methods such as adhesives or mechanical fasteners. This is because plastic welding does not require additional materials such as adhesives or fasteners, which can increase the cost of the joining process.

3. Versatile

Plastic welding is a versatile method that can be used to join different types of plastic materials such as thermoplastics, thermosets, and composites. This makes plastic welding suitable for a wide range of applications in various industries.

4. Clean and precise

Plastic welding is a clean and precise method that does not produce any harmful fumes or residues. This makes plastic welding suitable for applications where cleanliness and precision are essential.

5. Environmentally friendly

Plastic welding is an environmentally friendly method because it does not require additional materials such as adhesives or fasteners, which can create waste. Plastic welding also uses less energy compared to other joining methods such as welding or soldering.

Applications of Welded Plastic Parts

1. Automotive industry

Plastic welding is commonly used in the automotive industry to join plastic parts such as bumpers, dashboards, and other interior and exterior parts. Plastic welding is preferred over other joining methods because it creates a strong bond that is resistant to vibration, impact, and temperature changes. Plastic welding is also a cost-effective method compared to other joining methods such as adhesives or mechanical fasteners.

2. Medical industry

Plastic welding is used in the medical industry to join plastic parts of medical equipment and devices. The process of plastic welding is preferred in the medical industry because it creates a strong and leak-proof bond that is essential for medical devices. Plastic welding is also a clean and sterile process that is suitable for medical applications.

3. Packaging industry

Plastic welding is used in the packaging industry to join plastic films and sheets to create packaging materials such as bags, pouches, and containers. Plastic welding is preferred in the packaging industry because it creates a strong and durable bond that is essential for packaging materials. Plastic welding is also a cost-effective method compared to other joining methods such as adhesives or mechanical fasteners.

4. Construction industry

Plastic welding is used in the construction industry to join plastic pipes and fittings for plumbing and other applications. Plastic welding is preferred in the construction industry because it creates a strong and leak-proof bond that is essential for plumbing applications. Plastic welding is also a cost-effective method compared to other joining methods such as adhesives or mechanical fasteners.

5. Electronics industry

Plastic welding is used in the electronics industry to join plastic parts of electronic devices and equipment. Plastic welding is preferred in the electronics industry because it creates a strong and durable bond that is essential for electronic devices. Plastic welding is also a clean and precise method that is suitable for small and delicate plastic parts.

6. Aerospace industry

Plastic welding is used in the aerospace industry to join plastic parts of aircraft and spacecraft. Plastic welding is preferred in the aerospace industry because it creates a strong and lightweight bond that is essential for aircraft and spacecraft. Plastic welding is also a precise method that is suitable for complex plastic parts.