What is a tool holder?

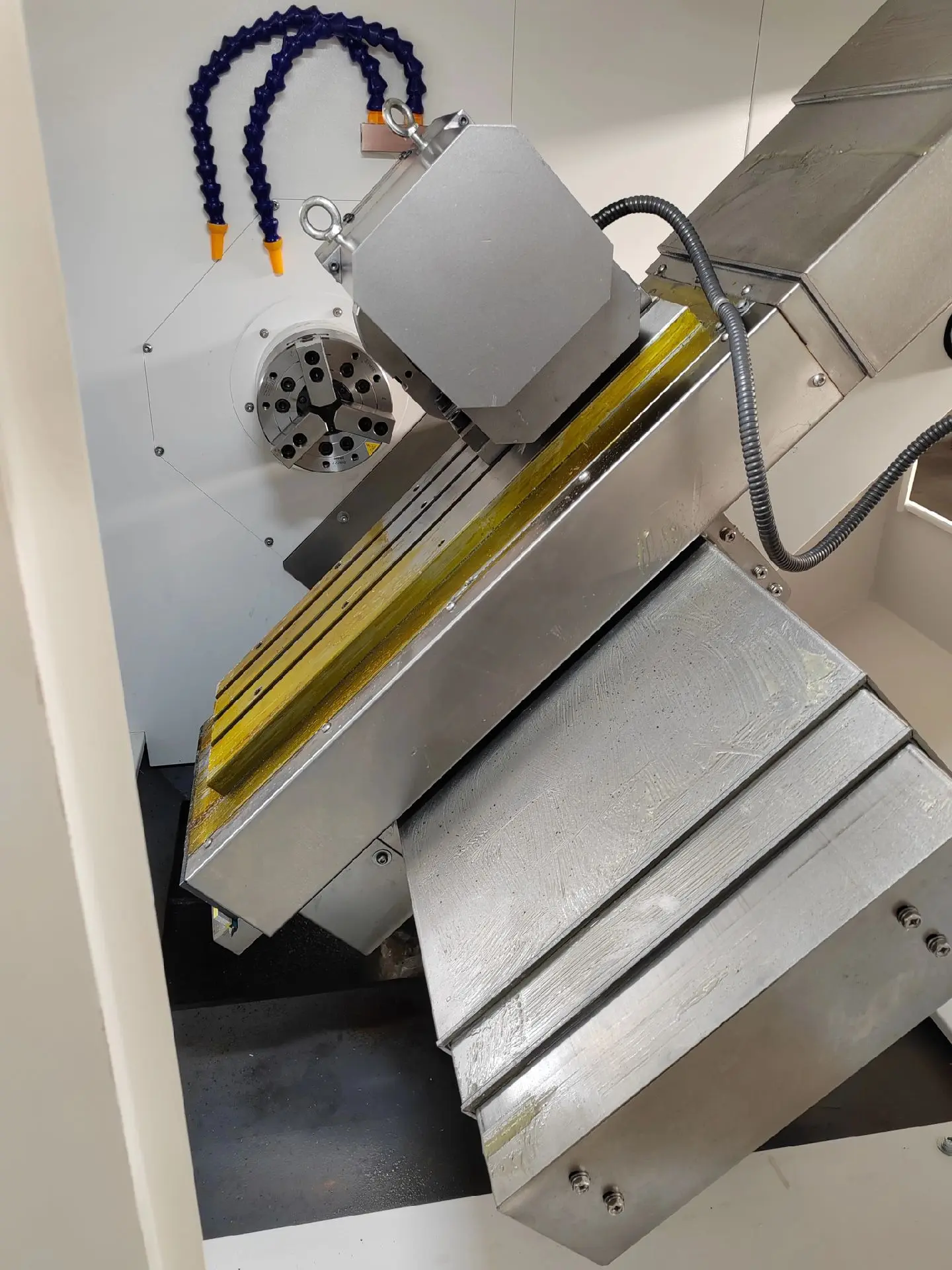

CNC machine tool is composed of a spindle, tool changer (tool holder and tool magazine manipulator), ball screw, and other functional components. Most of the machine tool companies through outsourcing and outsourcing of different functional components and combined assembly, build a complete machine tool.

Therefore, the reliability level of functional components will have a direct impact on the reliability level of the machine and CNC machining. Therefore, the key to improving the reliability level of CNC machine tools is to improve the reliability of key functional components of CNC machine tools.

The tool holder of a CNC machine tool is the mechanical component that supports and fixes the tool, which plays a crucial role in CNC machining. The design and function of the tool holder directly affect the machining accuracy, efficiency, and stability of the CNC machine tool.

It is one of the key functional components of a CNC lathe, and its reliability directly affects the stability and reliability of the whole machine. By realizing process integration and tool change automation, the CNC tool holder significantly reduces the time of tool change, and it ensures the positional accuracy of the lathe tool.

Components of a tool holder:

Main Structure: The main structure of the tool holder is usually made of cast iron or welded steel plate to ensure sufficient rigidity and stability. This part is subjected to cutting forces and various loads during the machining process.

Guideway System: The guideway system is responsible for supporting and guiding the movement of the tool and usually consists of linear guideways and components such as ball screws to ensure accurate and stable tool movement.

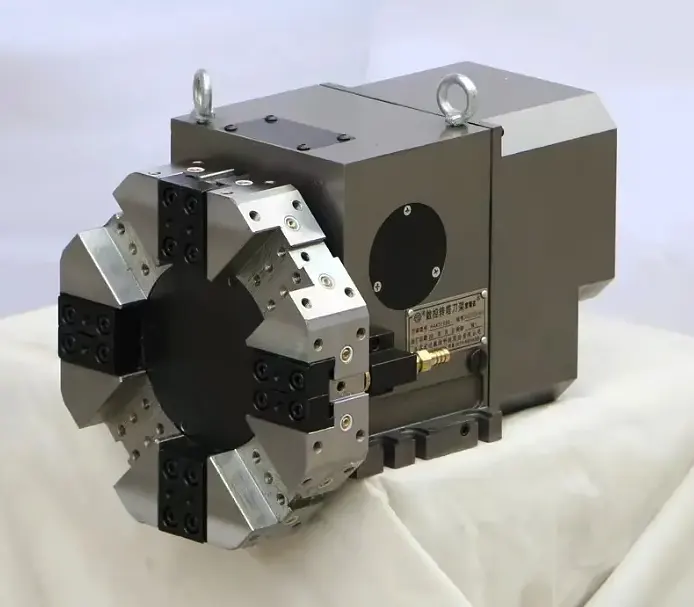

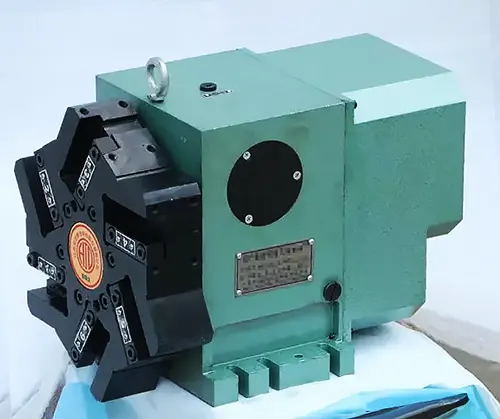

Tool clamping system: This part includes various components of the clamping tool, such as the chuck, clamping tool holder, etc., and its design directly affects the stability of the tool and the efficiency of tool change.

Tool Adjustment Device: The tool adjustment device allows small adjustments to be made to the tool to achieve accuracy and versatility in the machining process.

Cooling System: The cooling system is used to cool the tool to prevent overheating due to friction during the machining process and also helps to extend the tool’s life.

Holder Type:

CNC machine tool holders can be categorized into many types based on their application, structure, and characteristics. The following are some common types of CNC machine tool holders:

Horizontal Toolholders: Horizontal tool holders are horizontal tool holders with the tool perpendicular to the work plane. This type of holder is suitable for horizontal milling, drilling, and cutting operations.

Vertical Tool Holder: The vertical tool holder is a vertically oriented tool holder with the cutter horizontal to the work plane. It is typically used for vertical milling, drilling, and cutting operations.

Gantry Tool Holder: A gantry tool holder is a large tool holder structure in which the tool holder moves along a gantry structure that spans the entire machining area. This type of holder is commonly used for machining large workpieces such as steel structures, ships, and airplane parts.

Arm Type Tool Holder: An arm-type tool holder is a crossbeam type of tool holder with a tool holder that moves along an arm structure. This type of holder is often used to achieve complex workpieces such as automobile engine blocks and automobile frames.

Bridge-type tool holders: Bridge-type tool holders are similar to gantry-type tool holders, but are simpler in construction, with the tool holder spanning the work plane. This type of tool holder is usually used for higher precision requirements of processing, such as mold processing and precision parts processing.

Rotary tool holder: The rotary tool holder has the function of tool rotation, which can realize the machining of complex contours, such as curved surfaces and three-dimensional parts.

Compound tool holders: Compound tool holders combine the functions of multiple tool holders to realize a variety of machining operations, such as milling, drilling, tapping, and cutting.

Importance of the tool holder

Machining accuracy: The design and structure of the tool holder directly affect the machining accuracy of the CNC machine tool. A stable and solid tool holder can effectively minimize vibration and deformation, thus ensuring that the dimensions and surface accuracy of the machined parts meet the requirements.

Machining Efficiency: A well-designed tool holder can improve the machining efficiency of a CNC machine tool. It can support various cutting operations and ensure fast and accurate tool movement, thus reducing machining time and cost.

Stability: The stability of the tool holder is directly related to the stability of the CNC machine tool. A solid tool holder can effectively reduce vibration and oscillation during the machining process, ensuring the stability and reliability of the machining process.

Tool life: Proper tool holder design reduces tool wear and damage, thereby extending tool life and reducing replacement and maintenance costs.

Versatility: The design of the tool holder should also take into account the versatility of different machining requirements. It should be able to accommodate various types and sizes of tools and support different types of machining operations, thus increasing the application range and flexibility of the CNC machine tool.

History and Development

Since the middle of the 20th century, computer technology has developed rapidly, and digital control technology has been widely used in the manufacturing industry. The introduction of computers provides technical support for automation and precision control, and to work in concert with CNC technology to adapt to the new machining environment, CNC tool holders have emerged.

The generation of the CNC tool holder replaces the traditional manual tool holder and realizes the automatic tool change function of the lathe in the process of machining the workpiece.

The CNC tool holder as a key functional component of the CNC lathe, mainly bears the role of cutting tool clamping and replacement. The rigidity and indexing accuracy of the CNC tool holder plays a decisive role in determining the position of the tooltip, which directly affects the machining accuracy of the workpiece to be machined.

So far, the electric tool holder and hydraulic tool holder have occupied the main market of tool holders, and become the mainstream tool holder products, driven by electric motors electric tool holders are prevalent in Europe, while Japan and South Korea mainly promote hydraulic motor-driven CNC tool holder.

Since the 1950s, the United States K & T successfully developed the first automatic tool changer, and researchers in various countries began to focus on its reliability.

More representative tool holder companies mainly include Germany DMG MORI, the United States Haas Automation, Japan Mazak, and so on.

German DMG MORI CNC tool holders are famous for their high precision and high performance, and they are usually equipped with advanced tool management systems, which can monitor, manage, and optimize the status of the tool, thus improving the efficiency of the machine tool.

Haas Automation is an excellent manufacturer of CNC machine tools and cutting tools, specializing in the design and production of high-performance CNC machine tools and related accessories, known for its high-performance CNC tool holders. Haas Automation’s CNC tool holders usually include automatic turret systems, which can achieve rapid and automatic tool change and improve productivity.

Japan’s Mazak is also an excellent manufacturer of CNC machine tools. Its product line includes a variety of high-precision CNC tool holders, and its CNC tool holders are usually equipped with a multi-axis turret system, which realizes the automatic switching of multiple tools and improves cutting efficiency.

The main manufacturers of CNC tool holders in Taiwan, China include Luk Hsin Co., Ltd, Taiwan Sunrise International Precision Machinery Co., Ltd, and Taiwan Tex Co.

Conclusion

Facing the development wave of intelligence and integration, CNC machine tools have become the core carrier of manufacturing development. As an important part of the CNC machine, improving the reliability of CNC tool holders is a must for the development of high-quality products.

With the continuous breakthrough of scholars in reliability technology, the theory and engineering practice related to the reliability of CNC tool holders will be further developed.

hello!,I love your writing so a lot! proportion we keep in touch extra about your post on AOL?

I need a specialist on this area to solve my problem. Maybe that is you!

Looking ahead to peer you.

Pretty section of content. I simply stumbled upon your weblog and in accession capital to claim that I acquire actually enjoyed account your blog posts. Any way I’ll be subscribing on your feeds or even I success you get right of entry to persistently fast.

Thank you for creating a space where joy is not just a moment but a way of life!

“Thrilled to have found a blog that’s a testament to the beauty of structured and truthful reporting. Thank you for your dedication!”