Electrical Discharge Machining: Precision, Efficiency, and Innovation

When it comes to precision machining of hard and brittle materials, one technique that has gained popularity over the years is electrical discharge machining (EDM). EDM is a non-conventional machining process that uses electrical discharges to erode material from a workpiece. It is very precise and accurate, which makes it perfect for making complicated shapes and curves. The EDM process is particularly useful for achieving design features that other processes cannot—for example, sharp internal corners. It is widely used in the mold-making industry due to its unique capability to shape real hard metals.

What is Electrical Discharge Machining?

Electrical discharge machining (EDM) is a manufacturing process that uses electrical discharges to shape materials without physically contacting them. When traditional machining methods are insufficient, engineers often turn to EDM. Throughout the history of the industrial revolution, our manufacturing processes have limited our product design. As a result, we frequently verify whether the selected manufacturing process meets our desired specifications during and after the product design stage.

EDM changes this situation fundamentally. Unlike conventional processes like casting, forming, and other machining methods, it can achieve exceptionally high levels of precision using digital inputs. In this article, we will explore the different types of EDM processes, their benefits, and drawbacks, and help you select the best one for your needs. Keep reading to gain a deeper understanding of the various EDM processes.

Components of An EDM Machine

The components of an Electrical Discharge Machining (EDM) machine typically include:

Power supply

The power supply generates the electrical energy required for the EDM process. It provides the high voltage pulses that create the spark between the electrode and the workpiece.

Dielectric fluid system

The dielectric fluid system provides a non-conductive fluid that is used to cool and flush away the debris generated during the EDM process. It also serves as a medium for the electrical discharge to occur.

Workpiece holding device

The workpiece holding device secures the workpiece in place during the EDM process. It may include clamps, vises, or magnetic chucks.

Electrode

The electrode is a conductive material that is used to create the spark between the electrode and the workpiece. There are two types of electrodes: the tool electrode (used in a sinker and hole EDM) and the wire electrode (used in wire EDM).

Servo control system

The servo control system is responsible for controlling the movement of the electrode and the workpiece. It ensures that the electrode is positioned accurately and maintains the correct gap between the electrode and the workpiece.

CNC system

The CNC (Computer Numerical Control) system is used to program and control the EDM machine. It allows for precise and repeatable machining operations.

Spark generator

The spark generator creates the electrical discharge between the electrode and the workpiece. It generates a series of high-voltage pulses that ionize the dielectric fluid, creating a spark that erodes the workpiece material.

Electrical Discharge Machining Working Principle

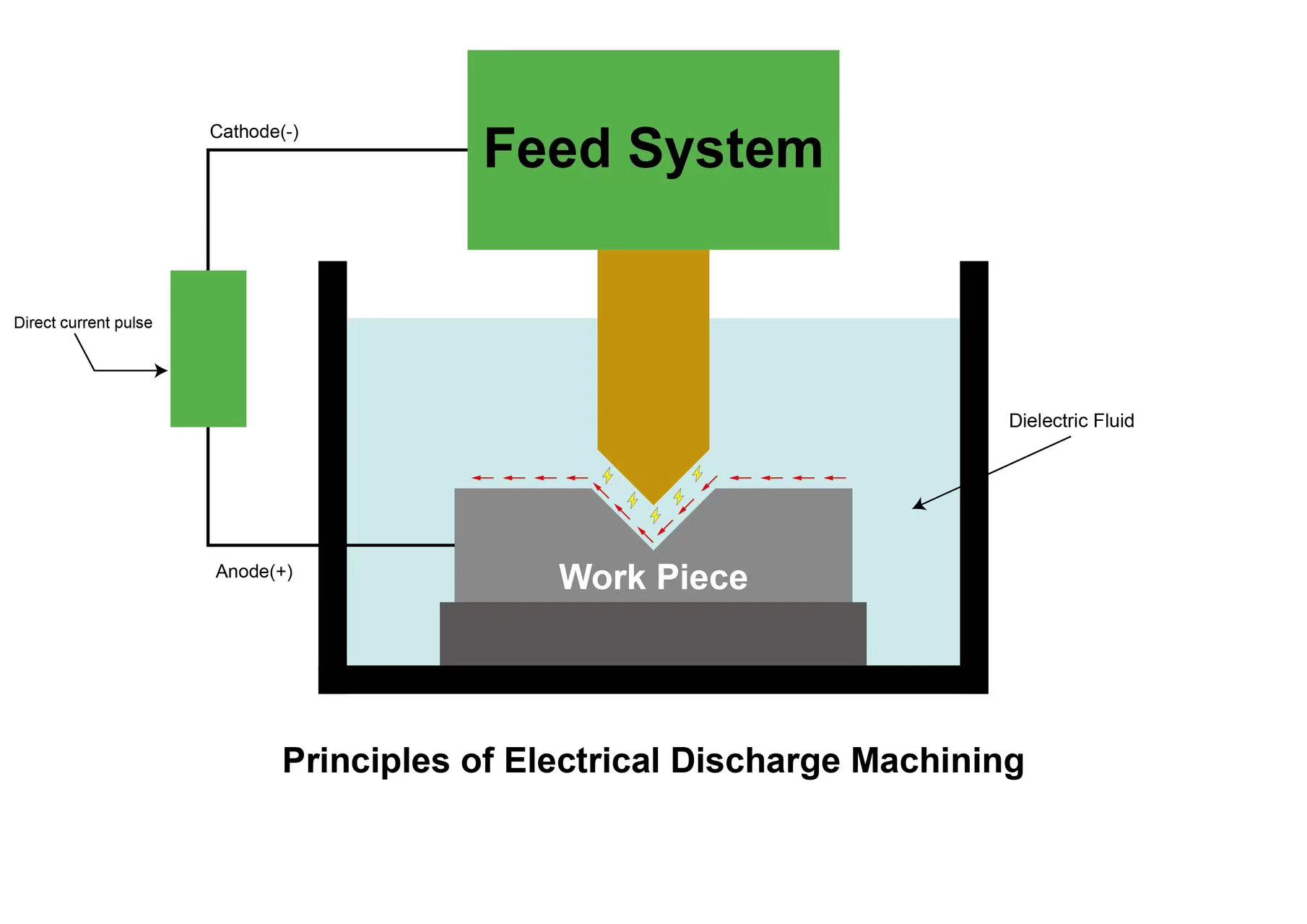

Three conditions are required for lightning to occur. 1. The clouds and the ground accumulate different charges, forming a voltage difference. 2. The distance between the clouds and the ground is small enough. 3. Non-conductive air medium, the conductivity increases due to rainy weather. When the three conditions are met, the originally non-conductive air will break through by an electric arc, and a large amount of heat will be released.

Like lightning, these three elements are also required for the generation of electric sparks. Two electrodes accumulate charges, a sufficiently small gap distance, and a medium with suitable conductivity.

In principle, an EDM machine is a machine that can precisely control these three factors to produce suitable sparks for processing conductive materials.

Solid electrical conductors, known as electrodes, are used to accumulate different charges and form a voltage difference. Typically, the tool electrode is referred to as the electrode while the workpiece electrode is called the workpiece. The spark is visible proof of the flow of electricity and generates intense heat, with temperatures soaring as high as 8000 to 12000 degrees Celsius. This heat melts or vaporizes almost any conductive material. The two electrodes are separated by a very narrow gap, and the electrical current is discharged repeatedly and rapidly up to millions of times per second without ever touching each other. Adaptive machine controls are used to maintain the spark gap, also known as the discharge gap or electrode gap, at a consistent and stable distance during the electric discharge machining process.

In electrical discharge machining, the spark is precisely controlled and confined to the surface of the material being worked on. Consequently, the EDM process typically has no impact on the heat treatment below the surface. The tool and workpiece are both immersed in a dielectric fluid, which is non-conductive and usually made up of deionized water.

The spark always occurs within the dielectric fluid, and the conductivity of the deionized water is carefully regulated to provide an optimal environment for the EDM process. In addition to facilitating the machining process, the deionized water cools the workpiece and carries away the small metal particles that are eroded during the process.

Types of Electrical Discharge Machining

The categorization of EDM into three distinct types enables you to have alternative options in case one method fails to satisfy your requirements. The three categories of electrical discharge machining include:

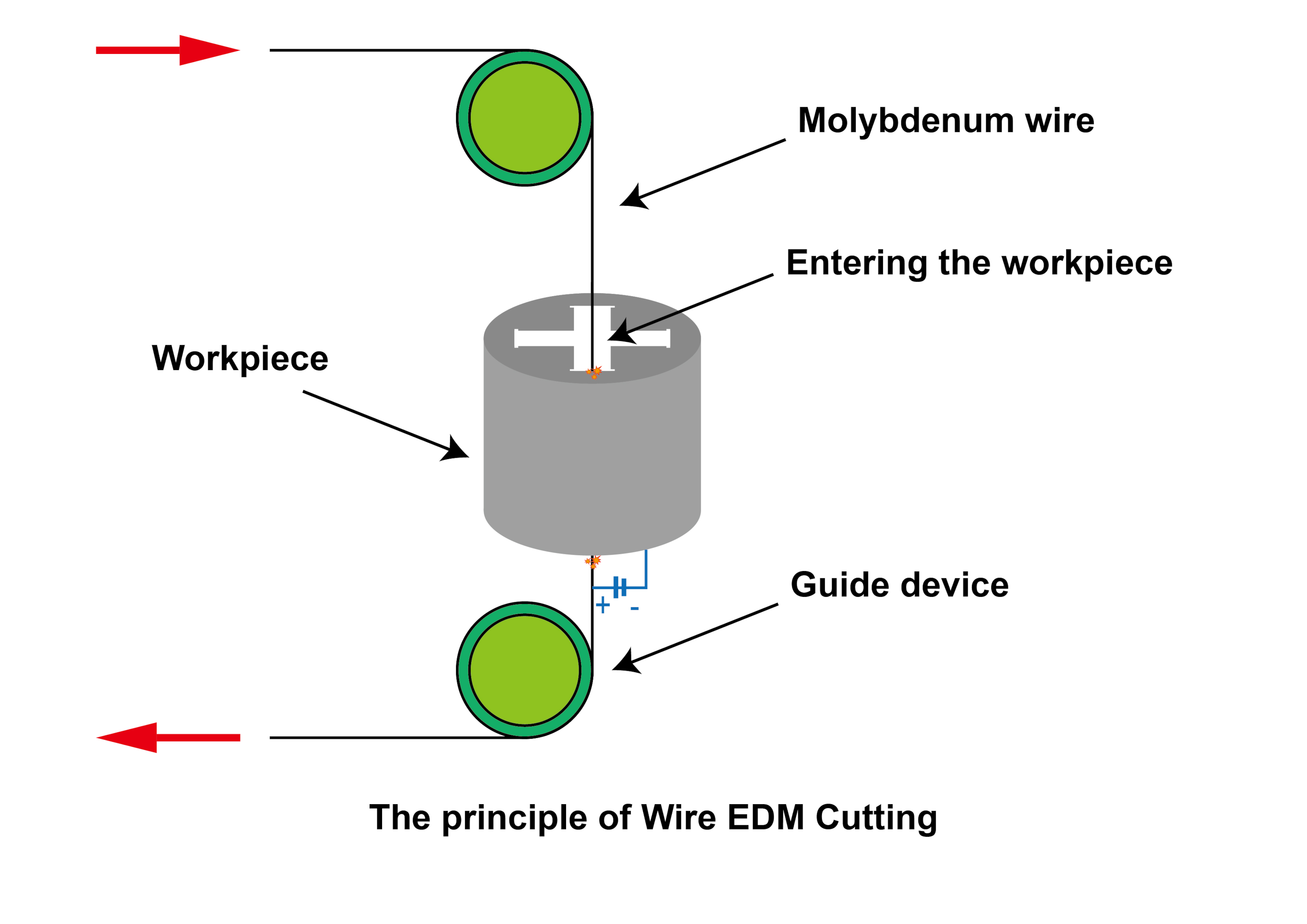

Wire EDM

Wire EDM (Electrical Discharge Machining) is a non-contact machining process that uses a thin, electrically charged wire to cut through a workpiece. The wire is guided along a pre-programmed path, which is usually controlled by a computer-aided design (CAD) system. The workpiece is submerged in a dielectric fluid to provide insulation and flush away the eroded material. As electrical current passes through the wire and the workpiece, sparks are generated that erode the material, resulting in a precise and accurate cut.

Hole EDM

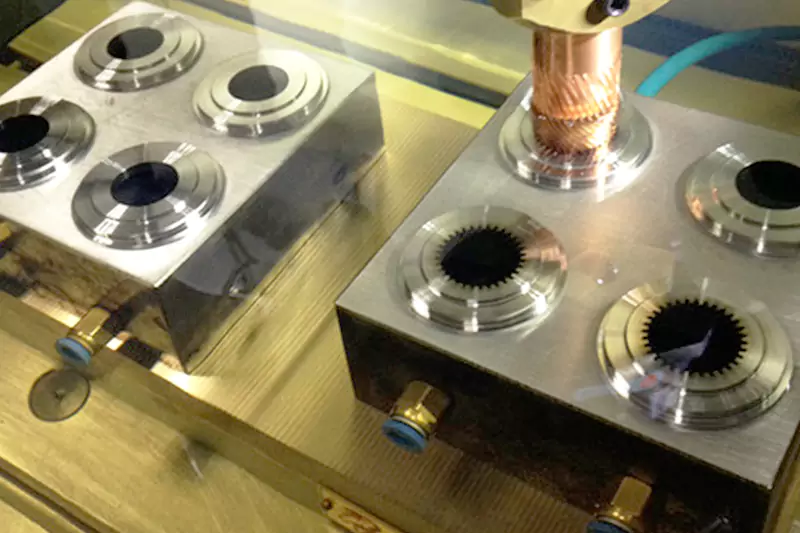

Hole EDM (Electrical Discharge Machining) is a process used to create precise and accurate holes in hard and difficult-to-machine materials. The process uses a tool electrode, typically made of copper or graphite, and a workpiece electrode. The tool is positioned close to the workpiece and a voltage difference is applied between the two electrodes, creating a spark or electrical discharge that erodes the material. This process is repeated until the desired hole size and shape are achieved.

Sinker EDM

Sinker EDM (Electrical Discharge Machining) is a process that uses a shaped electrode, typically made of graphite or copper, to erode material from a workpiece. The electrode is submerged in a dielectric fluid and positioned close to the workpiece, which is also submerged in the fluid. An electrical discharge or spark is generated between the electrode and the workpiece, which erodes the material and creates the desired shape.

Mirro EDM

So-called mirror EDM is basically a kind of Sinker EDM, but it creates a very fine surface on the workpieces. The surface’s roughness is better than 0.02 Ra or generally regard as a mirror surface.

The secret lies in the dielectric fluid. In order to achieve better surface roughness, the energy released by each spark should be decreased so the spark burns less metal each time and create a smaller ‘scar’ on the workpiece surface. This is done by adding very fine conductive powders (micro-powders) into the dielectric fluid so that the conductivity of the fluid increase a little and hence spark can be triggered easier and with less energy.

After conductive micro-powders enter the discharge gap, they act as multiple small conductors between the electrodes, which also distorts the electric field in the gap, reduces the breakdown strength of the insulating medium in the gap, and makes discharge more likely to occur, thereby increasing the size of the discharge gap.

The increased discharge gap reduces the inducing effect of the electric erosion products on the discharge and is conducive to the flow and discharge of the electric erosion products, reducing the concentration of discharge and making the discharge uniformly distributed on the machined surface.

With the increase of the discharge gap and the thickening of the discharge channel, the heated area of the machined surface increases while the heating intensity decreases under the same discharge pulse energy, resulting in large and shallow discharge craters on the surface.

At the same time, the increase of the discharge gap reduces the ability of the discharge to eject molten metal, causing more molten metal to solidify on the surface of the workpiece, further reducing the depth of the discharge crater. Therefore, the formation of large and shallow discharge craters on the machined surface is the fundamental reason for reducing the surface roughness in the powder-mixed electrical discharge machining process.

Advantages of Electrical Discharge Machining

Electrical Discharge Machining (EDM) offers several advantages over traditional machining processes such as milling, drilling, and grinding. Some of the key advantages of EDM include:

Ability to machine hard and difficult-to-machine materials

EDM can machine materials that are difficult or impossible to machine with conventional processes, including hardened tool steels, carbides, and titanium alloys.

Precision and accuracy

EDM can achieve very high levels of precision and accuracy, making it ideal for machining small or intricate components with complex geometries.

No physical contact

Since EDM is a non-contact machining process, there is no physical contact between the tool and the workpiece. This means that there is no tool wear and no residual stresses in the workpiece.

No burrs or surface damage

EDM can produce a very fine finish without creating burrs or surface damage on the workpiece.

Flexibility

EDM is highly flexible and can be used to create a wide range of shapes and geometries, including deep cavities, narrow slots, and complex shapes.

Automation

EDM machines can be easily automated using computer numerical control (CNC) systems, allowing for high-volume production and consistent quality.

Disadvantages of Electrical Discharge Machining

While Electrical Discharge Machining (EDM) offers several advantages over conventional machining processes, it also has some disadvantages that should be considered. Some of the key disadvantages of conventional EDM include:

The limited material removal rate

EDM is a relatively slow process and the material removal rate is limited compared to other machining processes such as milling and turning.

Cost

EDM can be a costly process, particularly for high-volume production runs.

Surface finish

Although EDM can produce a very fine finish, it may not be as smooth as that achieved by other machining processes.

Complexity

EDM is a complex process that requires specialized equipment and skilled operators.

Environmental impact

EDM produces a significant amount of waste material, including used dielectric fluid and electrode materials, which can have an environmental impact if not properly disposed of.

Safety

EDM involves the use of high-voltage electrical discharges, which can be hazardous if proper safety measures are not followed.

Applications of Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a versatile machining process that can be applied in various industries for different applications. Some of the common applications of EDM include:

Mold and die making

EDM is commonly used in the mold and die-making industry to create complex and intricate shapes in hard and difficult-to-machine materials such as tungsten carbide, hardened tool steels, and titanium alloys.

Aerospace

EDM is used in the aerospace industry to create components such as turbine blades, compressor blades, and aerospace engine components.

Medical manufacturing

EDM is used to create medical implants, surgical instruments, and other medical devices that require high precision and accuracy.

Automotive manufacturing

EDM is used in the automotive industry to create components such as fuel injectors, gears, and engine components.

Electronics manufacturing

EDM is used in the electronics industry to create small, intricate components such as microchips and printed circuit boards.

Tool and die repair

EDM is also used in tool and die repair to repair damaged or worn-out components.

Overall, EDM is a valuable machining process that offers unique advantages for certain applications, particularly those involving hard and difficult-to-machine materials or components with complex geometries.

Conclusion

In conclusion, Electrical Discharge Machining (EDM) is a highly precise and accurate machining process that uses electrical energy to erode workpiece material. EDM is a versatile machining process that can be applied in various industries for different applications. EDM offers unique advantages for certain applications, particularly those involving hard and difficult-to-machine materials or components with complex geometries.

Although EDM has some disadvantages, such as limited material removal rate and higher costs, it remains a valuable machining process in many industries due to its unique capabilities. Overall, EDM plays a crucial role in the manufacturing industry, enabling the creation of intricate and complex parts that would be impossible to make using other machining processes.